Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

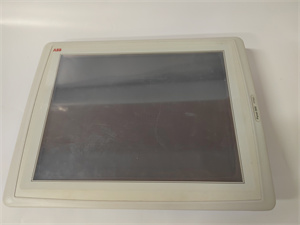

| Product Model | PP865 3BSE042236R1 |

| Manufacturer | ABB |

| Product Category | 15-inch TFT Operator Panel (Industrial HMI) |

| Front Panel Dimensions (W×H×D) | 398×304×6 mm |

| Mounting Depth | 60 mm (160 mm including clearance) |

| Front Panel Seal | IP66 |

| Rear Panel Seal | IP20 |

| Keyboard/Front Panel Material | Touch screen: Polyester on glass (1 million touch operations), Overlay: Autotex F157/F207 |

| Reverse Side Material | Powder – coated aluminum |

| Weight | 3.7 kg |

| Serial Ports | RS 422/RS 485 (25 – pin D – sub, female), RS232c (9 – pin D – sub, male) |

| Ethernet | Shielded RJ45 |

| USB Ports | Host type A (USB 1.1, max 500mA output), Device type B (USB 1.1) |

| Compact Flash Slot | Type I and II |

| Flash Memory (Application Storage) | 12 MB (including fonts) |

| Real – Time Clock | ± 20 ppm + ambient temp/supply voltage errors (max 1 min/month at 25 °C) |

| Battery Type | CR2450 (UL & CUL: Sanyo or Panasonic), minimum lifetime: 3 years, rechargeable |

| Power Consumption | Normal: 1.2 A, maximum: 1.7 A |

| Display Type | TFT – LCD (1024×768 pixels, 64 k color) |

| Backlight Lifetime | > 35,000 h at + 25 °C ambient |

| Active Display Area (W×H) | 304.1×228.1 mm |

| Fuse Type | Internal DC fuse, 3.15 A T (5×20 mm) |

| Power Supply | + 24 V DC (20 – 30 V DC), 3 – pin jack block |

| CE Compliance | IEC 60950, IEC 61558 – 2 – 4 |

| UL & CUL Compliance | Class II power supplies |

| Operating Temperature | Vertical installation: 0 °C to + 50 °C, Horizontal installation: 0 °C to + 40 °C |

| Storage Temperature | – 20 °C to + 70 °C |

| Relative Humidity | 5 – 85% (non – condensing) |

| Certifications | CE, UL 1604 Class I div 2, UL 508, UL 50 4x (indoor), DNV, NEMA 4x (indoor) |

| Noise Immunity | EN 61000 – 6 – 4 emission & EN 61000 – 6 – 2 immunity |

ABB PP865 3BSE042236R1

Product Introduction

ABB PP865 3BSE042236R1 is a 15 – inch TFT operator panel, meticulously engineered for industrial automation applications. As part of ABB’s high – end industrial HMI product line, it serves as a crucial interface between operators and industrial processes.

This operator panel provides a user – friendly interface that allows operators to monitor and control complex industrial processes with ease. The high – resolution TFT – LCD display, featuring 1024×768 pixels and 64k colors, offers crisp and accurate visualization of process data. Whether it is used in a manufacturing plant to oversee production lines or in a power generation facility to manage energy – related processes, PP865 3BSE042236R1 ensures that operators can access and act on critical information promptly. It also integrates well with ABB’s Panel 800 system, enhancing the overall automation environment’s coherence.

Core Advantages and Technical Highlights

- Exceptional Display Quality: The 1024×768 pixel resolution of the TFT – LCD display ensures that every detail of the process data, from complex graphs to numerical values, is presented clearly. In industries like pharmaceuticals, where precise monitoring of process variables is crucial for product quality, the sharp display enables operators to detect even the slightest changes accurately.

- Intuitive Touch Screen Interaction: With a touch screen made of polyester on glass, capable of withstanding 1 million touch operations, the panel offers an intuitive way for operators to interact with the HMI. In a fast – paced automotive manufacturing environment, workers can quickly navigate through different control screens, start or stop processes, and adjust parameters, reducing the time spent on manual input and minimizing errors.

- Function Keys for Added Control: In addition to touch screen functionality, the inclusion of function keys provides operators with additional control options. In a chemical plant, where emergency shutdowns or quick – access to specific process controls are necessary, these function keys can be programmed to perform critical functions instantly, enhancing safety and operational efficiency.

- Seamless System Integration: The PP865 3BSE042236R1‘s compatibility with ABB’s Panel 800 system simplifies the integration process. In a large – scale industrial complex with multiple ABB – based automation systems, this seamless integration ensures that data flows smoothly between different components, enabling unified control and monitoring across the entire facility.

- Rugged and Reliable Design: With an IP66 – sealed front panel and powder – coated aluminum rear panel, the operator panel is built to withstand harsh industrial environments. In mining operations, where dust and water splashes are common, or in food and beverage production facilities with frequent wash – down procedures, PP865 3BSE042236R1can continue to operate reliably, minimizing downtime due to equipment failure.

ABB PP865 3BSE042236R1

Typical Application Scenarios

- Manufacturing Industry: In automotive manufacturing plants, ABB PP865 3BSE042236R1is used to monitor and control the entire production line. Operators can view real – time data on vehicle assembly progress, check for any bottlenecks, and adjust conveyor speeds or robotic arm movements directly from the panel. This helps in maintaining high production efficiency and product quality.

- Chemical and Pharmaceutical Sectors: In chemical plants, the panel is used to monitor and control chemical reactions. Operators can adjust temperature, pressure, and flow rates in real – time, ensuring that reactions occur under optimal conditions. In pharmaceutical manufacturing, it is used to oversee the production of drugs, ensuring compliance with strict quality control standards by accurately monitoring process parameters.

- Power Generation and Energy Management: In power plants, PP865 3BSE042236R1allows operators to monitor the performance of generators, transformers, and other electrical equipment. They can adjust power output, manage grid connections, and respond to any faults or fluctuations in the power supply. In renewable energy facilities such as wind farms, it helps in monitoring the operation of wind turbines, including blade pitch adjustment and power generation optimization.

- Water Treatment and Environmental Monitoring: In water treatment plants, operators use the panel to monitor the water treatment process, including filtration, disinfection, and chemical dosing. They can adjust the operation of pumps, valves, and other equipment to ensure the production of clean water. In environmental monitoring stations, it is used to display data from various sensors, such as air quality monitors and water quality sensors, allowing for quick assessment of environmental conditions.

Related Model Recommendations

- PP860: A smaller – sized alternative to PP865 3BSE042236R1, with a different screen size but similar functionality. It is suitable for applications where space is limited, such as in small – scale industrial control cabinets or in certain mobile equipment control scenarios.

- PP880: An advanced model in the series, offering higher – resolution displays and more powerful processing capabilities. It is designed for applications that require handling of large amounts of data and complex graphical interfaces, such as in high – end process control systems or in large – scale data – intensive monitoring applications.

- Panel 800 – related Accessories: Products like specific cables, mounting brackets, and expansion modules that are designed to work in tandem with PP865 3BSE042236R1to enhance its functionality. For example, specialized cables can improve the stability of communication connections, and expansion modules can add extra I/O capabilities.

- ABB PLCs: ABB’s range of programmable logic controllers, which can be integrated with PP865 3BSE042236R1to form a complete automation control system. Different PLC models offer varying levels of processing power and I/O capacities, suitable for different scales of industrial applications.

- ABB Inverters: These can be controlled and monitored through PP865 3BSE042236R1in applications where variable – speed drives are used, such as in conveyor systems or in pumps and fans where energy – efficient speed control is required.

Installation, Commissioning and Maintenance Instructions

- Installation Preparation: Before installing ABB PP865 3BSE042236R1, ensure that the installation location meets the temperature and humidity requirements (operating temperature: 0 °C to + 50 °C for vertical installation and 0 °C to + 40 °C for horizontal installation; relative humidity: 5 – 85% non – condensing). Prepare the necessary tools, such as screwdrivers and wire strippers. Check the power supply to ensure it is within the specified range of + 24 V DC (20 – 30 V DC). Mounting should be done in a location that is easily accessible for operation and maintenance, and proper grounding should be ensured to protect against electrical interference.

- Maintenance Suggestions: Regularly clean the touch screen and the front panel of PP865 3BSE042236R1using a soft, dry cloth to keep the display clear and the touch screen responsive. Periodically check the connections of all ports (serial, Ethernet, USB) to ensure they are secure. If the backlight brightness decreases over time, consider replacing the backlight unit. The real – time clock battery (CR2450) should be replaced every 3 years to maintain accurate timekeeping. In case of any software – related issues, follow ABB’s recommended procedures for software updates and troubleshooting.

Service and Guarantee Commitment

ABB stands firmly behind PP865 3BSE042236R1 with a comprehensive service and guarantee package. The product comes with a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. ABB’s global network of technical support teams is available to provide assistance at any stage, from installation guidance to troubleshooting complex issues. In the event of a product failure, ABB ensures quick response times, with access to a vast inventory of spare parts to minimize downtime. Additionally, ABB offers training programs to help customers make the most of the panel’s features, and continuous product improvement initiatives ensure that the PP865 3BSE042236R1 remains at the forefront of industrial HMI technology, providing long – term value and reliability to customers.