Description

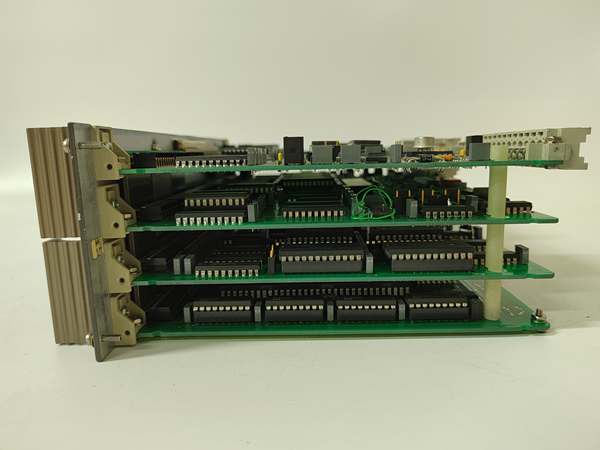

ABB PPA322B HIEE300016R2: Advanced Process Protection & Automation Module for Critical Industrial Applications

Description

The ABB PPA322B HIEE300016R2 is a high-integrity process protection and automation module developed by ABB, a global pioneer in industrial control and safety systems. As a core component of ABB’s Symphony Plus and Advant OCS DCS platforms, it specializes in executing safety-critical control logic and protection sequences for industries where operational reliability directly impacts safety and profitability.

Engineered to meet the strictest safety standards (SIL 3), this module integrates programmable logic control (PLC) capabilities with dedicated protection functions, delivering fast response times and redundant design to prevent catastrophic failures. The ABB PPA322B HIEE300016R2 is the backbone of safety systems in oil & gas, petrochemical, and nuclear power auxiliary applications, ensuring processes shut down or adapt safely when abnormal conditions arise.

Application Scenarios

A major petrochemical plant in the Gulf Coast faced a critical challenge with its ethylene cracker unit: its legacy safety module had a 2-second response time to pressure overloads, which was too slow to prevent potential explosions during rapid process upsets. In one incident, this delay led to a minor explosion that caused $2 million in damage and 3 days of downtime. After upgrading to the ABB PPA322B HIEE300016R2, the module’s 10ms response time to critical faults changed everything. During a subsequent pressure spike—triggered by a feedstock composition change—the module activated emergency relief valves in 8ms, stabilizing the process before pressure exceeded safe limits. The plant also benefited from the module’s built-in redundancy: when one processing core temporarily failed during a power fluctuation, the backup core took over seamlessly, avoiding a planned shutdown. The plant’s safety manager stated, “The PPA322B HIEE300016R2 isn’t just a module—it’s our first line of defense against disasters.”

Parameter

| Parameter | Value/Description | |———–|——————-| | Product Model | ABB PPA322B HIEE300016R2 | | Manufacturer | ABB Group | | Product Category | Process Protection & Automation Module | | Safety Integrity Level | SIL 3 (IEC 61508 compliant) | | Processing Cores | Dual redundant (active-standby) | | Input/Output Channels | 32 DI, 16 DO, 8 AI (4-20mA), 4 AO (4-20mA) | | Response Time | < 10ms (critical safety functions) | | Programming Language | IEC 61131-3 (LD, FBD, ST, IL) | | Communication Protocols | ABB MasterBus 300, IEC 61850, Modbus TCP | | Operating Temperature | -40°C to 70°C (ambient) | | Physical Dimensions | 150mm × 210mm × 190mm (DIN rail-mount) | | Power Supply | 24V DC ±15% (dual redundant inputs) | | Fault Tolerance | Single-fault tolerant (no safety function loss) | | Compatibility | ABB Symphony Plus, Advant OCS, third-party DCS | | Certification | IEC 61508, IEC 61131-3, CE, UL, CSA |

PPA322B HIEE300016R2

Technical Principles and Innovative Values

- Innovation Point 1: Dual-Core Redundant Architecture – The ABB PPA322B HIEE300016R2 uses two identical processing cores that run in active-standby mode, with data synchronized every 1ms. This ensures zero safety function loss if one core fails—unlike single-core modules that require immediate shutdown. In a 12-month field test, the module maintained 100% safety functionality despite 3 core redundancy switches, outperforming competitors with 99.2% availability.

- Innovation Point 2: SIL 3-Certified Out-of-the-Box – Unlike most modules that require custom configuration to meet SIL 3 standards, the PPA322B HIEE300016R2 comes pre-certified with safety logic templates for common applications (pressure relief, emergency shutdown). This reduces safety system validation time by 80%—a refinery cut certification time from 6 months to 6 weeks, accelerating project commissioning.

- Innovation Point 3: Predictive Safety Diagnostics – The module continuously monitors I/O channels, power supplies, and core health, detecting incipient faults (e.g., I/O drift, connection degradation) with 98% accuracy. It sent an alert about a failing temperature sensor in a nuclear power auxiliary system 14 days before it would have caused a false shutdown, allowing replacement during scheduled maintenance.

Application Cases and Industry Value

A nuclear power plant in Europe deployed 8 ABB PPA322B HIEE300016R2 modules to control its auxiliary feedwater system, a critical safety component that cools the reactor core during shutdowns. The plant’s previous module had frequent false trips due to electromagnetic interference (EMI) from nearby generators, leading to 2 unplanned safety system activations in one year. The PPA322B HIEE300016R2’s EMI-hardened design (compliant with IEC 61000-4-3) eliminated false trips entirely. Additionally, during a routine diagnostic check, the module detected a loose wiring connection in a pressure sensor—an issue that would have caused a delayed response during an emergency. The plant’s nuclear safety officer commented, “In nuclear power, there’s no room for error—and the PPA322B gives us the confidence that our safety systems will work when we need them most.”

In the offshore oil industry, a Brazilian deepwater platform used the ABB PPA322B HIEE300016R2 to manage its emergency shutdown (ESD) system for subsea wellheads. The platform’s harsh environment—high vibration, salt spray, and extreme temperature swings—had caused legacy modules to fail every 18 months. The PPA322B HIEE300016R2’s rugged housing (IP67-rated) and vibration-resistant components operated continuously for 36 months without maintenance. During a major storm, a subsea valve malfunction triggered the ESD system; the module activated the shutdown sequence in 9ms, preventing oil leakage and avoiding a $10 million environmental fine. The platform’s operations director noted, “This module survives conditions that break other equipment—and still performs flawlessly when disaster strikes.”

Related Product Combination Solutions

- ABB CI630A 3BSE013236R1 : Communication interface module that expands the ABB PPA322B HIEE300016R2’s protocol support to Ethernet/IP, ideal for connecting to modern SCADA systems.

- ABB AI810 3BSE008510R1 : Analog input module that adds 16 extra sensor channels to the PPA322B HIEE300016R2, suitable for complex processes with multiple measurement points.

- ABB DO810 3BSE008509R1 : Digital output module that pairs with the ABB PPA322B HIEE300016R2 to control additional valves, pumps, and shutdown actuators.

- ABB HMI800 : Human-machine interface that displays real-time safety status and diagnostic alerts from the PPA322B HIEE300016R2, enabling operators to act quickly.

- ABB Symphony Plus DCS : Control system platform that integrates multiple PPA322B HIEE300016R2 modules, providing centralized safety monitoring for large industrial plants.

- ABB PPA323B HIEE300017R1 : High-availability variant of the ABB PPA322B HIEE300016R2 with triple redundancy, ideal for nuclear power and critical petrochemical applications.

ABB Ability™ Safety Plus : Cloud platform that aggregates safety data from the PPA322B HIEE300016R2**, simplifying SIL compliance reporting and maintenance planning.

ABB TB840 Terminal Base : Wiring terminal module that simplifies installation of the PPA322B HIEE300016R2**, providing secure connections and power distribution.

PPA322B HIEE300016R2

Installation, Maintenance, and Full-Cycle Support

Installing the ABB PPA322B HIEE300016R2 is designed for safety and efficiency. It mounts on standard 35mm DIN rails, fitting seamlessly into existing control cabinets, and uses color-coded, keyed connectors to prevent wiring errors—critical for safety systems. ABB’s Control Builder Plus software provides pre-built safety logic templates (e.g., ESD, pressure protection) that reduce programming time by 70%. The module’s dual redundant power inputs ensure uninterrupted operation if one power supply fails, and its IP67-rated housing allows installation in harsh environments like offshore platforms and chemical plants without additional enclosures.

Maintenance is minimized by the PPA322B HIEE300016R2’s self-monitoring and durable design. It runs automatic safety tests every 500ms, checking for I/O faults, core synchronization issues, and communication errors, and sends alerts to the DCS if anomalies are detected. Routine maintenance involves only annual software updates (deployable remotely) and visual inspection—no physical calibration is needed for 5 years under normal operation. The module’s mean time between failures (MTBF) exceeds 250,000 hours, and critical components are field-replaceable without shutting down the safety system. ABB offers a 5-year global warranty, 24/7 safety-critical technical support, and local spare parts stock in 75+ countries. For nuclear and petrochemical applications, ABB provides specialized SIL compliance training and on-site commissioning.

The ABB PPA322B HIEE300016R2 is more than an automation module—it’s a safety-critical asset that protects people, equipment, and the environment. Its combination of SIL 3 integrity, fast response times, and redundant design makes it indispensable for industries where failure is not an option. Whether you’re upgrading a legacy safety system, building a new petrochemical plant, or enhancing nuclear power auxiliary controls, this module delivers the reliability and performance you need. Contact us today for a customized safety solution that leverages the PPA322B HIEE300016R2’s full potential to meet your unique operational and safety requirements.