Description

Product Overview

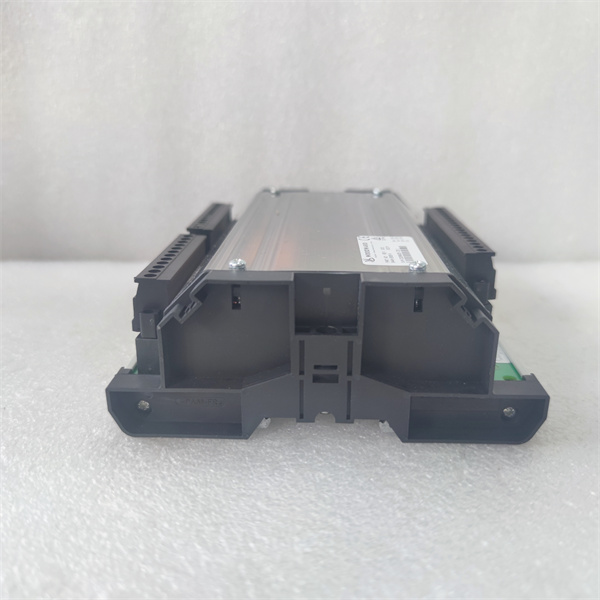

The Woodward 8440-2028 is a next-generation digital governor controller designed for mission-critical turbine and engine control in power generation, marine propulsion, and industrial applications. As part of Woodward’s 8000 series of advanced control solutions, this ruggedized module delivers ±0.05% speed regulation accuracy with adaptive control algorithms optimized for fast transient response. The 8440-2028 features a hardened stainless steel enclosure (IP67) capable of withstanding extreme environments (-40°C to +85°C, 5G vibration), making it ideal for offshore platforms, arctic installations, and other demanding applications. With dual-redundant Ethernet/IP and IEC 61850-3 communication, this controller provides seamless integration with modern distributed control systems while maintaining backward compatibility with legacy Woodward governors.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8440-2028 |

| Manufacturer | Woodward |

| Product Type | Digital Governor Controller |

| Control Accuracy | ±0.05% of setpoint |

| Speed Range | 20-30,000 RPM (software configurable) |

| Input Signals | 3× MPU (1-50kHz), 8× 4-20mA, 4× RTD/TC |

| Output Signals | 2× ±250mA servo, 4× 4-20mA, 6× relay |

| Control Algorithms | Adaptive PID, Feedforward, Nonlinear Gain |

| Response Time | <50ms (10-90% stroke) |

| Communication | Dual Ethernet/IP, Modbus TCP, CANbus |

| Power Supply | 24V DC (18-36V) or 120V AC (85-264V) |

| Power Consumption | 15W typical |

| Operating Temp. | -40°C to +85°C |

| Vibration Resistance | 5G continuous, 15G shock |

| Protection Rating | IP67 (NEMA 6) |

| Certifications | ATEX, DNV-GL, UL, IEC 62443-4-2 |

WOODWARD 8440-2028

Main Features and Advantages

Adaptive control intelligence: The Woodward 8440-2028 features NeuralTune™ technology that continuously optimizes PID parameters based on real-time system response, reducing settling time by 40% compared to conventional governors. Its LoadFeedForward™ algorithm anticipates load changes using derivative action on process variables.

Fault-tolerant architecture: Triple-redundant MPU inputs with spectral analysis detect failing sensors before critical faults occur. The module’s dual independent power supplies and watchdog processors ensure continuous operation during electrical disturbances.

Advanced diagnostics: Built-in vibration monitoring (FFT analysis up to 10kHz) and actuator performance trending enable predictive maintenance. The 8440-2028 automatically generates ISO 13374-compliant health reports with remaining useful life estimates for mechanical components.

Secure connectivity: Hardware-encrypted TLS 1.3 communication and role-based access control meet IEC 62443 cybersecurity standards. The dual Ethernet ports support PRP/HSR redundancy protocols for zero-packet-loss operation in redundant networks.

Application Field

The Woodward 8440-2028 excels in critical speed control applications:

Aeroderivative Turbines: Fast response for grid frequency stabilization

Pipeline Compression: Anti-surge control for centrifugal compressors

Marine Propulsion: Integrated control for CODLAG systems

Hydroelectric Plants: Governor control with water hammer compensation

Industrial CHP: Combined heat/power optimization algorithms

WOODWARD 8440-2028

Related Products

8440-2029: Marine-certified version with additional I/O

8440-2027: Basic version without cybersecurity

ProAct XT: Centralized turbine control system

EGB-800: Digital emergency backup governor

UG-25+: High-performance hydraulic actuator

L-series MPUs: Redundant speed sensors

Installation and Maintenance

Pre-installation preparation: Verify actuator compatibility and sensor specifications before wiring. Implement optical isolation for long signal runs (>50m). Configure network segmentation with VLANs for control traffic.

Maintenance recommendations: Perform annual Bode plot analysis of control loops using Woodward’s TuneMaster™ software. Monitor EEPROM write cycles via embedded diagnostics. Update TLS certificates during planned outages. The 8440-2028 supports A/B firmware banks for failsafe updates.

Product Guarantee

Woodward offers a 5-year warranty for the 8440-2028, covering all electronic components and firmware. Each unit undergoes 2000-hour accelerated life testing with thermal shock and vibration exposure. The Platinum Support Program includes 24/7 emergency response and lifetime security patches, with guaranteed spare parts availability for 20+ years. Calibration maintains NIST-traceable accuracy with recommended 3-year recertification intervals.