Description

Product Introduction

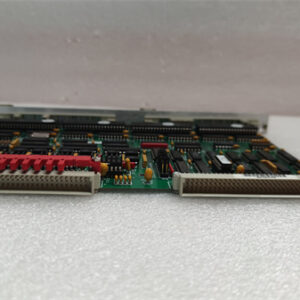

The AMAT 0021-53986 is a high-efficiency, high-power-density DC power module designed for various semiconductor manufacturing processes. It is part of the AMAT power series and is used in critical applications such as diffusion furnaces, etching machines, deposition equipment, cleaning devices, and testing equipment. This module provides stable and reliable power support, ensuring smooth operation and high precision in semiconductor manufacturing processes.

Core Advantages and Technical Highlights

High Efficiency and Power Density: The AMAT 0021-53986 offers up to 95% efficiency and a power density of 3 kW/L, making it highly energy-efficient and suitable for compact devices.

Wide Input Voltage Range: With an input voltage range of 180 V to 460 V DC, the module can adapt to various power supply requirements.

Low Ripple and Noise: Ensures stable power supply for sensitive equipment, enhancing reliability and performance.

High Reliability: The module is designed with high-quality materials and stringent manufacturing standards, ensuring long-term reliability in harsh environments.

Comprehensive Safety Standards: Complies with multiple safety standards such as UL, CE, and RoHS, ensuring safe operation.

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | AMAT 0021-53986 |

| Manufacturer | Applied Materials (AMAT) |

| Product category | Industrial Control Module |

| Input Voltage | 180 V to 460 V DC |

| Input Current | 100 A |

| Output Voltage | 24 V DC |

| Output Current | 125 A |

| Power | 3000 W |

| Efficiency | Up to 95% |

| Power Density | 3 kW/L |

| Operating Temperature Range | 0°C to 50°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Protection Rating | IP20 |

| Dimensions (W x H x D) | 483 mm x 254 mm x 133 mm |

| Weight | 25 kg |

| Communication Protocols | Modbus, Profibus |

| Compatibility | Compatible with AMAT PMAX systems and other specific models |

AMAT 0021-53986

Typical Application Scenarios

The AMAT 0021-53986 is widely used in the semiconductor manufacturing industry:

-

Diffusion Furnaces: Provides stable power for thermal processes.

-

Etching Machines: Ensures precise control during etching processes.

-

Deposition Equipment: Supports high-precision deposition processes.

-

Cleaning Devices: Ensures reliable operation during cleaning processes.

-

Testing Equipment: Provides stable power for testing semiconductor devices.

Related Model Recommendations

-

AMAT PMAX Systems: Compatible with various AMAT PMAX systems for optimized process control.

-

AMAT Process Chambers: Works seamlessly with AMAT process chambers for integrated high-temperature control.

AMAT 0021-53986

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Ensure the environment meets the specified temperature and humidity requirements (0°C to 50°C, 5% to 95% RH non-condensing). Use shielded cables and proper grounding to minimize electromagnetic interference. Follow AMAT’s guidelines for mounting, ensuring proper ventilation and protection from dust.

Maintenance Suggestions: Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation. Use AMAT’s dedicated software for module configuration and firmware updates. Follow AMAT’s guidelines for handling sensitive components, including anti-static measures during maintenance.

Service and Guarantee Commitment

Applied Materials stands behind the quality and reliability of the 0021-53986, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Their dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.