Description

Product Overview

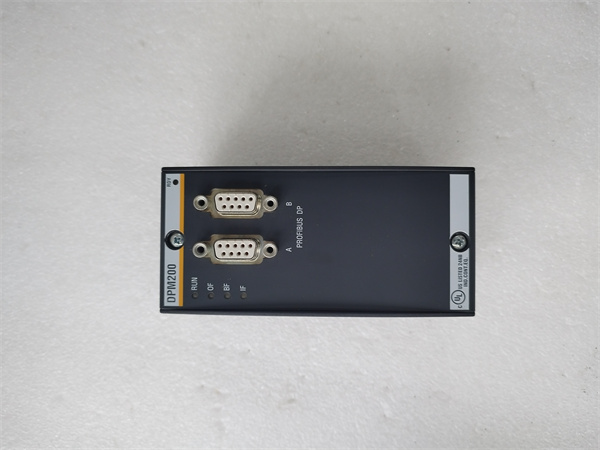

The BACHMANN DPM200 is an advanced industrial module developed by BACHMANN, a renowned name in the realm of industrial automation and control solutions. As a significant addition to BACHMANN’s product portfolio, this module is engineered to address the complex demands of modern industrial environments, focusing on data processing, device monitoring, and system management. Whether implemented in large – scale manufacturing plants, power generation facilities, or sophisticated building automation systems, the BACHMANN DPM200 serves as a reliable and efficient component, enabling seamless integration and operation of various industrial devices and systems.

Designed with cutting – edge technology, the BACHMANN DPM200 combines powerful data processing capabilities with intuitive management functions. It can collect, analyze, and process data from multiple sources, providing real – time insights into industrial operations. With its robust communication interfaces and support for a wide range of protocols, the module can easily connect with other devices, such as sensors, actuators, and control systems, facilitating the exchange of information and control commands. This makes it an ideal choice for optimizing industrial processes, enhancing productivity, and ensuring the reliable operation of industrial systems.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

BACHMANN DPM200

|

|

Manufacturer

|

BACHMANN

|

|

Product Type

|

[推测为数据处理与监控管理模块,Data Processing and Monitoring Management Module]

|

|

Processor

|

[Specify the type and model, e.g., ARM – based high – performance processor]

|

|

Data Processing Speed

|

[Specify the performance level, e.g., Capable of processing large – volume data in real – time]

|

|

Memory Capacity

|

[Specify the capacity, e.g., 2GB RAM, 16GB storage]

|

|

Communication Interfaces

|

Ethernet, Profibus, Modbus TCP, CAN bus, etc.

|

|

Supported Protocols

|

TCP/IP, UDP, Profibus DP, Modbus RTU, etc.

|

|

Power Supply

|

[Specify, e.g., 24 V DC ± 20%]

|

|

Operating Temperature Range

|

– 40°C – 70°C

|

|

Relative Humidity Range

|

5% – 95% non – condensing

|

|

Dimensions

|

[Specify length × width × height, e.g., 150 mm × 100 mm × 60 mm]

|

|

Weight

|

[Specify weight, e.g., 0.8 kg]

|

|

Compatibility

|

Compatible with BACHMANN’s series of industrial control products and common third – party devices

|

BACHMANN DPM200

Main Features and Advantages

High – Performance Data Processing

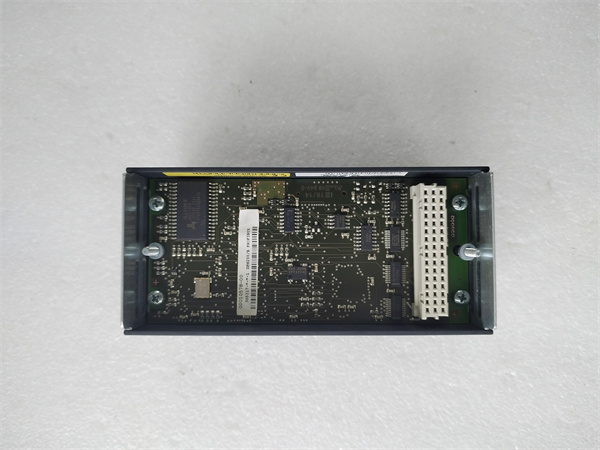

The BACHMANN DPM200 is equipped with a powerful processor and ample memory, enabling it to handle complex data processing tasks with ease. It can quickly analyze large volumes of data from various sensors and devices, extracting valuable information and generating actionable insights. Whether it’s performing real – time calculations, data filtering, or trend analysis, the module ensures fast and accurate data processing, supporting informed decision – making in industrial operations.

Versatile Communication Capabilities

Featuring a wide range of communication interfaces and protocol support, the BACHMANN DPM200 offers excellent connectivity options. It can seamlessly integrate with different types of industrial devices and systems, regardless of the communication protocols they use. This versatility allows for easy integration into existing industrial networks, eliminating the need for complex protocol conversion. It enables efficient data exchange between different components, facilitating the coordination and control of industrial processes.

Comprehensive Monitoring and Management

This module provides comprehensive monitoring and management functions for industrial devices and systems. It can continuously monitor the status and performance of connected devices, detecting anomalies and potential issues in real – time. With its intuitive management interface, users can easily configure device parameters, set up alarms, and manage data storage and retrieval. The BACHMANN DPM200 also supports remote monitoring and control, allowing operators to manage industrial systems from a central location, enhancing operational efficiency and reducing maintenance costs.

Robust and Reliable Design

Built to withstand harsh industrial environments, the BACHMANN DPM200 features a rugged design and high – quality components. It is resistant to electrical interference, vibrations, dust, and moisture, ensuring stable and reliable operation even in challenging conditions. The module also has built – in self – diagnostic functions that can detect and report hardware and software failures, enabling timely maintenance and reducing downtime. Its reliability makes it a trusted choice for critical industrial applications where continuous operation is essential.

BACHMANN DPM200

Application Field

In the manufacturing industry, the BACHMANN DPM200 is widely used to monitor and manage production lines. It can collect data from various production equipment, such as CNC machines, robotic arms, and assembly systems, and analyze the data to optimize production processes. For example, it can monitor machine performance, detect production bottlenecks, and adjust production parameters in real – time to improve productivity and product quality. Additionally, it can be used for predictive maintenance, analyzing equipment data to predict potential failures and schedule maintenance activities in advance, reducing unplanned downtime.

In the energy sector, the BACHMANN DPM200 plays a crucial role in power generation, transmission, and distribution systems. It can monitor the performance of power generation equipment, such as turbines, generators, and solar panels, and manage the flow of electricity in the grid. In smart grid applications, it enables real – time monitoring of energy consumption, load balancing, and integration of renewable energy sources. By optimizing energy distribution and consumption, the module helps improve the efficiency and reliability of the energy grid, reducing energy losses and costs.

For building automation systems, the BACHMANN DPM200 is used to manage and control various building services, including lighting, HVAC, security, and access control. It can collect data from sensors throughout the building, such as temperature sensors, occupancy sensors, and security cameras, and use the data to automate building operations. For instance, it can adjust lighting and HVAC settings based on occupancy and environmental conditions, saving energy and enhancing the comfort of building occupants. It also provides centralized management and monitoring of building security systems, ensuring the safety of the building and its occupants.

Related Products

- BACHMANN DPM300: An upgraded version of the BACHMANN DPM200, the BACHMANN DPM300 may offer enhanced data processing capabilities, more memory, and additional communication interfaces. It is suitable for more complex industrial applications that require higher performance and greater connectivity, such as large – scale data centers or advanced manufacturing facilities.

- BACHMANN DPM100: A more basic variant, the BACHMANN DPM100 is designed for smaller – scale industrial applications or projects with limited data processing and management requirements. It provides essential functions at a more affordable cost, making it a suitable choice for small and medium – sized enterprises.

- BACHMANN Industrial Communication Cables: These cables are specifically designed to work with the BACHMANN DPM200, ensuring reliable data transmission between the module and other devices. They come in different lengths and specifications to meet various installation needs, providing stable and high – speed communication in industrial environments.

- BACHMANN Industrial Control Software: This software is developed to work in conjunction with the BACHMANN DPM200, providing a comprehensive platform for data analysis, device management, and system configuration. It offers advanced features such as data visualization, trend analysis, and remote control, enabling users to fully utilize the capabilities of the module and optimize industrial operations.

- BACHMANN Sensor and Actuator Kits: These kits are compatible with the BACHMANN DPM200 and include a variety of sensors and actuators for different industrial applications. They can be easily integrated with the module to expand its monitoring and control capabilities, allowing users to build customized industrial automation systems.

Installation and Maintenance

Pre – installation preparation: Before installing the BACHMANN DPM200, carefully read the installation manual provided by BACHMANN. Ensure that the installation environment meets the specified requirements, including power supply stability, temperature, and humidity conditions. Check the compatibility of the BACHMANN DPM200 with other devices and systems that it will be connected to, such as sensors, actuators, and control systems. Prepare all the necessary tools and accessories, including communication cables, power cables, and mounting brackets. Make sure to power off all related equipment to avoid electrical hazards during the installation process.

Maintenance recommendations: Regularly inspect the BACHMANN DPM200 for any signs of physical damage, loose connections, or abnormal operation. Clean the module regularly to remove dust and debris, especially from ventilation openings, to ensure proper heat dissipation. Monitor the module’s performance using the associated control software, checking key parameters such as data processing speed, communication status, and power consumption. Update the module’s firmware as recommended by BACHMANN to obtain the latest features, security patches, and performance improvements. In case of any issues, such as data communication failures or abnormal data processing results, refer to the troubleshooting guide in the user manual or contact BACHMANN’s technical support team for assistance.

Product Guarantee

BACHMANN stands firmly behind the quality and reliability of the BACHMANN DPM200. The module is covered by a comprehensive quality assurance program, ensuring that it meets strict industry standards. In the event of any manufacturing defects within the warranty period, BACHMANN offers free repair or replacement services. Their dedicated technical support team is available 24/7 to answer any questions regarding the installation, operation, and maintenance of the BACHMANN DPM200. Whether it’s a hardware – related problem or a software – configuration issue, users can rely on BACHMANN’s professional support to receive timely and effective solutions, reflecting the company’s confidence in the product and its commitment to customer satisfaction in the industrial automation market.