Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 330180-91-CN |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Calibration tool for vibration sensors |

| Calibration type | Portable dynamic calibration system |

| Compatible sensors | 3300 series velocity sensors, proximity probes, and accelerometers |

| Frequency range | 1 Hz to 10,000 Hz |

| Amplitude range | 0.01 mm to 50 mm peak-to-peak (displacement); 0.1 mm/s to 100 mm/s (velocity) |

| Accuracy | ±1% of reading (frequency); ±2% of reading (amplitude) |

| Display type | 4.3-inch color LCD with touchscreen interface |

| Power source | Rechargeable lithium-ion battery (8 hours continuous use) |

| Data storage | 32 GB internal memory, supports USB data export |

| Dimensions | 220mm x 150mm x 80mm (width x height x depth) |

| Weight | 1.2 kg (2.65 lbs) |

| Operating temperature | 0°C to 50°C (32°F to 122°F) |

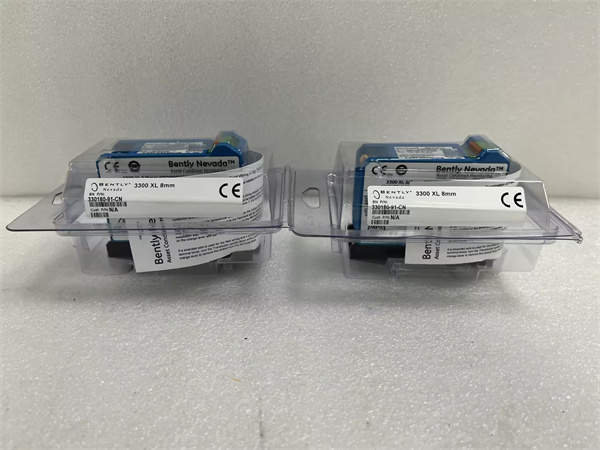

BENTLEY 330180-91-CN

Product introduction

The 330180-91-CN from Bently Nevada is a state-of-the-art portable calibration tool, specifically designed to verify and calibrate vibration sensors in industrial machinery monitoring systems. As an essential accessory in Bently Nevada’s 3300 series ecosystem, the 330180-91-CN ensures that sensors like velocity probes, proximity transducers, and accelerometers maintain accurate measurement performance over time.

Engineered for field and workshop use, the 330180-91-CN simplifies the calibration process with its intuitive interface and broad compatibility. It generates precise vibration signals across a wide frequency and amplitude range, allowing technicians to validate sensor output against known standards. By ensuring sensor accuracy, the 330180-91-CN plays a critical role in maintaining reliable machinery health monitoring—helping prevent false alarms, missed faults, and costly downtime in industries ranging from power generation to manufacturing.

Core advantages and technical highlights

Versatile compatibility: The 330180-91-CN supports calibration of nearly all Bently Nevada 3300 series sensors, including velocity sensors like the 330106-05-30-10-02-CN, proximity probes, and accelerometers. This versatility eliminates the need for multiple calibration tools, streamlining maintenance workflows and reducing equipment costs. It also works with select third-party sensors, making it a flexible solution for mixed-system environments.

Precision performance: With ±1% frequency accuracy and ±2% amplitude accuracy, the 330180-91-CN delivers laboratory-grade results in a portable form factor. Its ability to generate stable vibrations from 1 Hz to 10,000 Hz covers the full measurement range of most industrial sensors, ensuring comprehensive calibration. This precision is critical for maintaining the integrity of vibration data used in predictive maintenance programs.

Field-friendly design: The 330180-91-CN is built for industrial environments, with a rugged housing that withstands drops and vibrations. Its rechargeable battery provides 8 hours of continuous use—enough for a full day of on-site calibrations—while the lightweight (1.2 kg) design reduces technician fatigue during extended use. The touchscreen interface simplifies operation, allowing even less-experienced users to perform accurate calibrations with minimal training.

Typical application scenarios

In power plant maintenance, the 330180-91-CN is used during scheduled outages to calibrate vibration sensors on turbines, generators, and pumps. By verifying the accuracy of sensors like the 330106-05-30-10-02-CN mounted on turbine bearings, it ensures that vibration data used to assess machinery health is reliable. This is particularly critical for preventing false shutdowns of critical power generation equipment, which can result in significant revenue losses.

Within oil and gas refineries, the 330180-91-CN supports calibration of sensors in hazardous areas (when used with appropriate safety protocols). Technicians use it to validate proximity probes and velocity sensors on compressors and pipeline pumps, ensuring that measurements of shaft vibration and position are accurate. This helps refineries comply with industry safety standards and avoid unplanned shutdowns due to sensor drift.

In manufacturing facilities with predictive maintenance programs, the 330180-91-CN is part of routine sensor maintenance schedules. It calibrates vibration sensors on motors, fans, and conveyor systems, ensuring that early warning systems for bearing wear or imbalance are trustworthy. By maintaining sensor accuracy, the 330180-91-CN helps extend equipment life and reduce maintenance costs.

BENTLEY 330180-91-CN

Related model recommendations

330180-90-CN: A basic version of the 330180-91-CN with a narrower frequency range (1 Hz to 5,000 Hz), suitable for simpler calibration tasks.

330180-92-CN: An advanced model with automated calibration sequences, offering enhanced data logging compared to the 330180-91-CN.

330106-05-30-10-02-CN: A velocity sensor commonly calibrated using the 330180-91-CN, ideal for vibration monitoring in rotating machinery.

330130-080-00-CN: A proximity probe that pairs with the 330180-91-CN for calibration of shaft displacement measurements.

330150-020-00-00: A cable extension kit often used with sensors calibrated by the 330180-91-CN, ensuring proper signal transmission during testing.

3500/22-01-00: A display module that integrates data from sensors calibrated with the 330180-91-CN, providing visual monitoring of machinery health.

330138-040-00-05: A signal conditioner that, when paired with the 330180-91-CN, ensures both sensor and conditioning electronics are calibrated as a system.

Installation, commissioning and maintenance instructions

Setup preparation: Before using the 330180-91-CN, ensure the work area is clean and free from excessive vibration or electromagnetic interference. Charge the battery fully (4 hours) before field use to avoid interruptions. For sensor calibration, secure the sensor to the 330180-91-CN’s vibration table using compatible mounting hardware—match the sensor’s mounting thread (e.g., 5/8-18 UNF for the 330106-05-30-10-02-CN) to ensure proper coupling. Connect the sensor output to the calibration tool’s input port using shielded cables to minimize noise.

Maintenance suggestions: Inspect the 330180-91-CN before each use for physical damage, especially to the vibration table and connectors. Clean the touchscreen with a soft, dry cloth to maintain responsiveness. Calibrate the tool itself annually using Bently Nevada’s factory standards to ensure its accuracy. Store the device in the provided carrying case when not in use, and avoid exposure to extreme temperatures or moisture. Replace the battery every 2-3 years (or when runtime drops below 4 hours) with a genuine Bently Nevada replacement to maintain performance.

Service and guarantee commitment

The 330180-91-CN is backed by a 2-year warranty, covering defects in materials and workmanship under normal use conditions. Bently Nevada’s technical support team provides expert assistance for setup, troubleshooting, and calibration procedures, with 24/7 availability for critical issues.

We offer specialized training courses for the 330180-91-CN, teaching technicians how to perform accurate sensor calibrations and interpret results. For customers requiring traceable calibration, we provide factory certification services that document the 330180-91-CN’s performance against international standards. With Bently Nevada’s commitment to quality, the 330180-91-CN ensures reliable sensor calibration, supporting the integrity of your machinery monitoring systems for years to come.