Description

Detailed parameter table

| Parameter name | Parameter value |

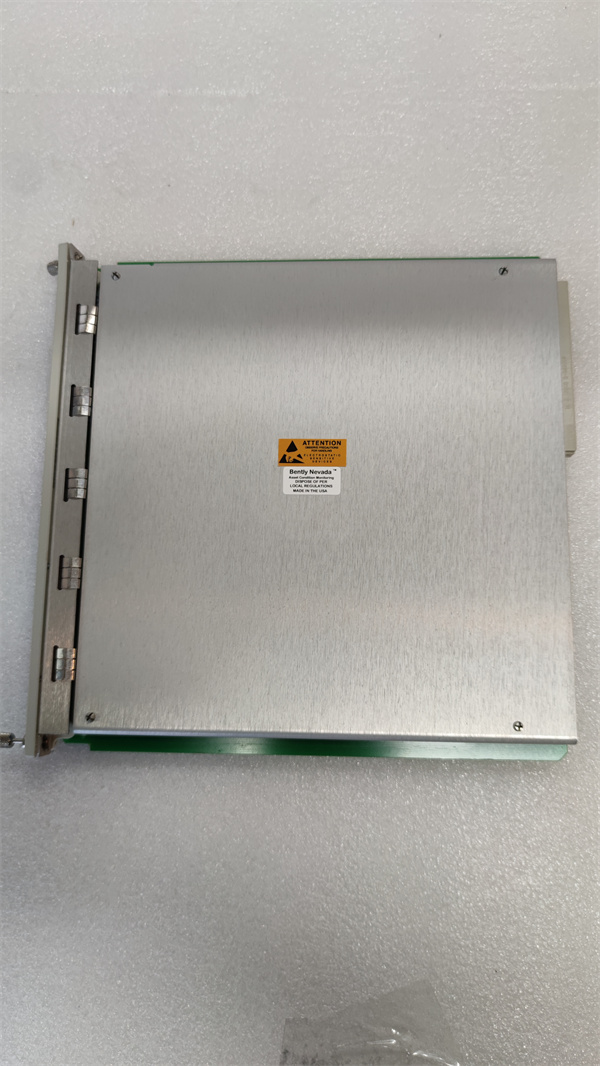

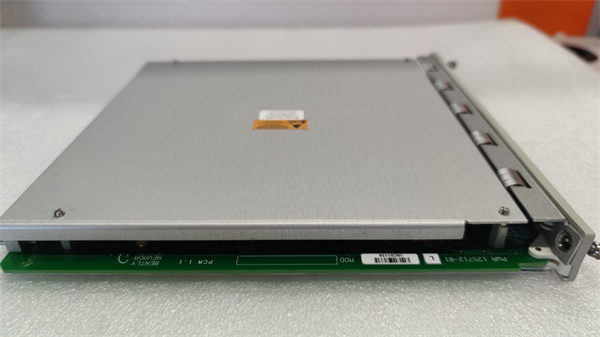

| Product model | 125712-01 (variant of 3500/32) |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System I/O Module |

| Channel configuration | 8 configurable input channels, 4 relay output channels |

| Input type support | 4-20 mA, mV, RTD (Pt100/Pt1000), thermocouple (Type J/K/T/E/R/S/B) |

| Output rating | 5 A @ 250 VAC, 5 A @ 30 VDC per relay |

| Sampling rate | 100 Hz per input channel |

| Accuracy | ±0.1% of reading (analog inputs), ±0.5°C (temperature inputs) |

| Operating voltage | 5 VDC, ±15 VDC (from 125744-02 rack backplane) |

| Power consumption | 6 W typical, 8 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Compatibility | 125744-02 racks, 140734-01 gateways, 136711-01 sensor cables |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 125712-01

Product introduction

The 125712-01 from Bently Nevada is the standard production variant of the 3500/32 input/output module, serving as a critical interface component in 3500 Machinery Protection Systems. This precision-engineered module enables the seamless integration of diverse process and temperature measurements into machinery health monitoring strategies, bridging specialized vibration monitoring components with general industrial sensors. As the most widely deployed variant of the 3500/32 series, 125712-01 provides the flexible I/O capabilities needed to create comprehensive protection solutions.

Bently Nevada’s 125712-01 module connects directly to the 125744-02 rack backplane, consolidating data from temperature sensors, pressure transmitters, and other process instruments alongside vibration data from 136711-01 connected sensors. Its measurements are integrated into the system data stream, accessible through 140734-01 communication gateways for both real-time monitoring and historical analysis. This integration empowers users to develop protection logic that combines machinery condition and process parameters, enhancing diagnostic capabilities and enabling more informed decision-making.

Core advantages and technical highlights

Multi-signal compatibility: The 125712-01 supports a comprehensive range of input types without requiring external signal conditioning, including RTDs, multiple thermocouple types, 4-20 mA loops, and mV-level signals. This versatility eliminates compatibility barriers, allowing users to connect diverse sensors directly to the module and simplify overall system architecture.

Precision measurement: Equipped with high-performance analog-to-digital converters and advanced cold-junction compensation, 125712-01 delivers consistent measurement accuracy across all input types. This precision ensures that temperature, pressure, and process variables are monitored with the same reliability as vibration data, enabling meaningful correlation between process conditions and equipment health.

Configurable relay logic: Four independently programmable relays in 125712-01 provide flexible actuation capabilities for alarms, shutdowns, or control functions. Relay behavior can be customized to respond to complex conditions involving both module inputs and data from other 3500 system components, supporting sophisticated protection strategies tailored to specific machinery requirements.

Plug-and-play integration: Designed exclusively for 3500 series racks, 125712-01 connects directly to the 125744-02 backplane for both power and communication. This integration ensures automatic system recognition, immediate data availability to all connected components, and simplified configuration through standard 3500 software tools.

Typical application scenarios

In power generation facilities, 125712-01 modules installed in 125744-02 racks form a critical component of turbine protection systems. They monitor bearing temperatures via RTD inputs, lubrication system pressures through 4-20 mA transmitters, and control valve positions, integrating this data with vibration measurements from 136711-01 connected sensors. The module’s relays provide essential actuation for cooling system adjustments, alarm notifications, and emergency shutdown sequences based on combined machinery health and process conditions.

Oil and gas processing plants utilize 125712-01 to integrate process parameters into compressor protection systems. The module connects to thermocouples monitoring interstage temperatures, pressure transmitters measuring discharge pressure, and seal gas flow sensors, providing the process context needed to interpret vibration data accurately. Its configurable relays trigger appropriate responses—from maintenance alerts to emergency shutdowns—based on predefined thresholds for combined parameters.

Manufacturing facilities deploy 125712-01 in production line machinery protection systems, connecting to motor winding temperature sensors, hydraulic pressure transmitters, and lubricant quality monitors. By correlating this process data with vibration measurements, the module helps distinguish between mechanical faults and process-induced issues, enabling more targeted maintenance and reducing unnecessary production downtime.

BENTLY 125712-01

Related model recommendations

3500/32: Base I/O module series that includes the 125712-01 variant.

125744-02: Rack assembly that houses and powers 125712-01 modules.

140734-01: Communication gateway that transmits data from 125712-01 to external systems.

136711-01: Sensor cable whose vibration data complements 125712-01 measurements.

3500/22M: Power supply module that provides operating power to 125712-01 via rack.

3500/60 163179-01: Display module that visualizes data from 125712-01 inputs.

3500/42M: Vibration monitor whose data is combined with 125712-01 measurements.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 125712-01, verify compatibility with the target 125744-02 rack firmware version and ensure the power supply can accommodate the additional load. Gather required tools including torque screwdriver, multimeter, and configuration laptop with 3500 software. Inspect the module for shipping damage, particularly checking input/output connectors and backplane pins. Review sensor specifications to confirm compatibility with module input ranges and wiring requirements.

Maintenance suggestions: Include 125712-01 in quarterly system inspections, verifying status LEDs indicate normal operation and checking communication with the system controller. Perform annual calibration using certified standards to maintain measurement accuracy, with special attention to temperature inputs requiring cold-junction verification. Test relay outputs during scheduled maintenance by activating each relay manually and verifying contact operation with a multimeter. Keep module firmware updated to ensure compatibility with latest system features and 140734-01 communication protocols.

Service and guarantee commitment

Bently Nevada provides 125712-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, relay functionality, and communication capabilities. Our technical support team offers expert guidance on configuration, calibration procedures, and integration with 125744-02 racks and other 3500 system components.

We offer specialized training on 125712-01 programming, signal conditioning, and protection logic development specific to industrial applications. Beyond the warranty period, our service agreements include calibration verification, technical support, and expedited replacement services to minimize system downtime. Bently Nevada’s commitment to quality ensures reliable performance of 125712-01 throughout its operational lifecycle, backed by our global network of service professionals.