Description

Detailed parameter table

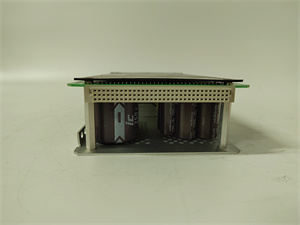

| Parameter name | Parameter value |

| Product model | 127610-01 (integral to 3500/15 relay module) |

| Manufacturer | Bently Nevada |

| Product category | Relay Output Module Core Assembly |

| Series affiliation | 3500 Machinery Protection System |

| Output channels | 8 Form C relay outputs (changeover contacts) |

| Contact rating | 5 A @ 250 VAC, 5 A @ 30 VDC resistive load |

| Response time | <10 ms from command to contact operation |

| Operating voltage | 5 VDC, ±15 VDC (powered by 3500/05-01-02-00-00-01) |

| Power consumption | 6 W typical, 8 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Protection features | Relay contact monitoring, overcurrent protection |

| Compatibility | 125720-01 transmitters, 3500/61 displays, 3500/34 gateways |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Diagnostic features | Contact weld detection, status LEDs per channel |

BENTLY 127610-01

Product introduction

The 127610-01 from Bently Nevada represents the core relay assembly within the 3500/15 relay output module, serving as the critical actuation component in 3500 Machinery Protection Systems. This precision-engineered assembly converts digital protection commands into physical relay operations, enabling automated safety actions when machinery parameters exceed safe thresholds. As the operational heart of the 3500/15 module, the 127610-01 acts as the system’s executive element, translating analytical insights from monitoring devices like the 125720-01 temperature transmitter into tangible protective responses.

Bently Nevada’s 127610-01 addresses industrial safety requirements where reliable protection actuation is mission-critical. Its 8-channel relay configuration provides flexible mapping to specific machinery conditions, ensuring appropriate responses—from warning alarms to emergency shutdowns—when abnormal temperatures, vibrations, or pressures are detected. This assembly ensures that critical protection decisions from the 3500 system are executed with millisecond precision, preventing equipment damage and ensuring operational safety.

Core advantages and technical highlights

Precision actuation capability: The 127610-01 features high-integrity Form C relays with <10 ms response time, ensuring rapid execution of protection sequences when triggered by 125720-01 temperature alarms or vibration alerts. This speed is critical for preventing catastrophic damage to rotating machinery during upset conditions.

Enhanced fault tolerance: Equipped with continuous contact monitoring, the assembly detects potential failures like welded contacts or open coils before they compromise protection. Diagnostic data is transmitted to 3500/61 displays, providing advance warning of relay issues during routine operations.

Flexible protection mapping: Each of the 8 independent relays can be programmatically assigned to specific protection scenarios, allowing system designers to create tiered response strategies. This flexibility enables customized safety protocols that balance operational availability with equipment protection.

Robust industrial design: Built to withstand harsh industrial environments, the 127610-01 maintains reliable operation across a 0°C to +60°C temperature range. Its rugged construction ensures consistent performance in vibration-prone settings typical of power generation, oil and gas, and manufacturing facilities.

Typical application scenarios

In turbine protection systems, the 127610-01 assembly acts as the final safety layer, with relays triggering turbine trips, fuel isolation, and auxiliary cooling activation when 125720-01 transmitters detect excessive bearing temperatures. This rapid response prevents bearing seizure and catastrophic turbine damage during temperature excursions.

Oil and gas compressor installations utilize the 127610-01 to implement multi-stage protection, with dedicated relays for warning alarms, compressor unloading, and emergency shutdown. When vibration or temperature thresholds are crossed, the assembly activates pre-configured responses while providing status updates to 3500/61 displays for operator visibility.

Manufacturing facilities integrate the 127610-01 into production line safety systems, where relays control motor disconnects, conveyor stops, and process interlocks. The assembly ensures immediate isolation of faulty equipment when 125720-01 transmitters detect overheating motors, preventing production line damage and ensuring worker safety.

BENTLY 127610-01

Related model ecosystem

3500/15 (Bently Nevada): Housing module containing the 127610-01 relay assembly.

125720-01 (Bently Nevada): Temperature transmitter whose alarms trigger relay actions.

3500/61 (Bently Nevada): Display module monitoring 127610-01 relay status.

3500/34 (Bently Nevada): Gateway transmitting relay status to enterprise systems.

3500/05-01-02-00-00-01 (Bently Nevada): Power supply for the relay system.

3500/20 (Bently Nevada): Rack housing the 3500/15 module with 127610-01.

135137-01 (Bently Nevada): Input module providing trigger signals to the relays.

Maintenance and service

The 127610-01 requires periodic maintenance as part of the 3500/15 module service schedule, including quarterly verification of LED status indicators against 3500/61 display reports. During scheduled shutdowns, perform relay operation tests to ensure contact integrity, particularly for relays that rarely actuate under normal conditions. Inspect contacts for arcing or wear and verify resistance with a multimeter.

Bently Nevada provides a 36-month warranty for the 127610-01 assembly, covering manufacturing defects and performance issues. Our service agreements include functional testing, contact cleaning, and expedited replacement to ensure protection system availability. Technical support is available for relay configuration, protection strategy development, and diagnostic interpretation specific to this critical safety component.