Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 133292-01 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Sensor termination junction box |

| Channel count | 4-channel input/output configuration |

| Connector type | MIL-C-5015 compatible connectors (input/output); terminal block for power |

| Cable compatibility | Compatible with 3300 series proximity probes and velocity sensors |

| Operating voltage | 24V DC (power input) |

| Operating temperature | -40°C to 85°C (-40°F to 185°F) |

| Enclosure rating | IP66 (NEMA 4X) for dust and water resistance |

| Housing material | Die-cast aluminum with epoxy coating |

| Dimensions | 150mm x 120mm x 80mm (width x height x depth) |

| Mounting method | Wall or surface mount with stainless steel hardware |

| Weight | 1.2 kg (2.65 lbs) |

| Compliance | CE, RoHS, ATEX Zone 2 (optional) |

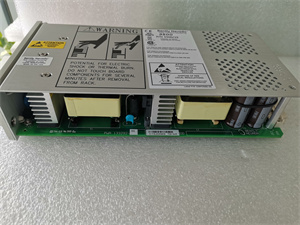

BENTLY 133292-01

Product introduction

The 133292-01 from Bently Nevada is a rugged sensor termination junction box, engineered to provide reliable connection and protection for industrial vibration and position sensors in machinery monitoring systems. As a critical connectivity component in Bently Nevada’s ecosystem, the 133292-01 serves as the interface between field sensors and monitoring modules like the 3500/15 speed monitor, ensuring secure signal transmission in harsh industrial environments.

Designed specifically for 3300 series proximity probes, velocity sensors, and other industrial transducers, the 133292-01 simplifies sensor wiring while protecting connections from environmental hazards. Its 4-channel configuration allows centralized termination of multiple sensors, reducing cable clutter and simplifying maintenance. Whether deployed in power plants, refineries, or manufacturing facilities, the 133292-01 enhances system reliability by safeguarding critical sensor connections against moisture, dust, and mechanical damage.

Core advantages and technical highlights

Industrial-grade protection: The 133292-01 features an IP66 (NEMA 4X) rated enclosure constructed from die-cast aluminum with an epoxy coating, providing superior resistance to water, dust, corrosion, and impact. This robust housing protects sensitive sensor connections from harsh environmental conditions, including washdowns, chemical exposure, and extreme temperatures (-40°C to 85°C). The sealed design ensures reliable operation in both indoor control cabinets and outdoor installations.

Simplified wiring management: With its 4-channel configuration and clearly labeled terminals, the 133292-01 streamlines sensor installation and maintenance. It eliminates the need for complex field wiring by providing a centralized termination point, making it easier to identify, test, and replace individual sensors. The junction box’s organized layout reduces wiring errors during installation and simplifies troubleshooting, minimizing system downtime.

Signal integrity preservation: The 133292-01 incorporates design features that maintain sensor signal integrity, including proper grounding terminals and shield connection points. These features prevent electromagnetic interference (EMI) and radio frequency interference (RFI) from corrupting sensor signals, ensuring accurate data transmission to monitoring modules like the 3500/15. The box’s internal wiring is optimized for low noise, preserving the precision of vibration and speed measurements.

Typical application scenarios

In power generation facilities, the 133292-01 is installed near turbine-generator sets to terminate proximity probes and vibration sensors monitoring shaft position and speed. Mounted on turbine skids or nearby structures, it protects sensor connections from the high temperatures, oil mist, and vibration typical in turbine environments. By centralizing connections for multiple sensors, the 133292-01 simplifies maintenance during planned outages, allowing technicians to quickly access and test sensor connections without navigating complex wiring harnesses.

Within offshore oil platforms, the 133292-01 provides protected termination for sensors monitoring pump and compressor health in harsh marine environments. Its corrosion-resistant housing withstands salt spray and humidity, while the IP66 rating prevents water ingress during platform washdowns. The junction box’s compact design allows installation in space-constrained areas, while its organized wiring facilitates quick sensor replacement during emergency repairs.

In steel mills, the 133292-01 protects sensor connections from the dust, vibration, and temperature extremes common in rolling mill operations. Mounted near motors and gearboxes, it terminates sensors monitoring bearing vibration and shaft position, ensuring reliable data transmission to central monitoring systems. The junction box’s rugged construction withstands the mechanical shocks and vibrations inherent in steel manufacturing, maintaining connection integrity despite constant equipment movement.

BENTLY 133292-01

Related model recommendations

133292-02: An 8-channel variant of the 133292-01, suitable for larger sensor arrays requiring more termination points.

133292-03: A hazardous area-rated version of the 133292-01 with ATEX Zone 1 certification for explosive environments.

3500/15: A speed monitoring module that receives signals via the 133292-01 from proximity probes and magnetic pickups.

330130-080-00-CN: A proximity probe commonly connected through the 133292-01 for shaft position measurement.

128229-01: An extension cable used to connect sensors to the 133292-01 junction box in remote installations.

330180-91-CN: A calibration tool that interfaces with sensors through the 133292-01 during system calibration.

3500/22-01-00: A display module that visualizes data from sensors connected via the 133292-01 junction box.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 133292-01, select a location within 3 meters of the monitored machinery to minimize cable length. Ensure the mounting surface is flat, stable, and protected from direct heat sources. Use the provided stainless steel hardware to secure the junction box, torquing screws to 2.5 Nm (22 in-lbs) for secure mounting. Verify that the installation area meets the environmental specifications (-40°C to 85°C) and that the box is oriented to prevent water pooling on the cover.

Maintenance suggestions: Inspect the 133292-01 quarterly to ensure the cover remains properly sealed—check for signs of damage to the gasket or enclosure. Tighten any loose cover screws to maintain the IP66 rating. Clean the exterior with a damp cloth as needed, avoiding harsh chemicals that could damage the epoxy coating. During sensor maintenance, use the junction box’s labeled terminals to isolate individual sensors for testing or replacement. Ensure all shield connections remain secure to maintain signal integrity, and retighten terminal screws annually to prevent loosening from vibration.

Service and guarantee commitment

The 133292-01 is backed by a 3-year warranty covering defects in materials and workmanship under normal operating conditions. Bently Nevada’s global technical support team provides expert guidance on installation, wiring, and maintenance of the 133292-01, with 24/7 availability for critical system inquiries.

We offer detailed installation guides and wiring diagrams specific to the 133292-01, ensuring proper integration with Bently Nevada sensors and monitoring modules. For customers requiring specialized configurations, our engineering team can provide custom wiring solutions optimized for specific applications. Backed by Bently Nevada’s decades of experience in industrial connectivity, the 133292-01 delivers reliable sensor termination you can trust to protect your machinery monitoring investments.