Description

Detailed parameter table

| Parameter name | Parameter value |

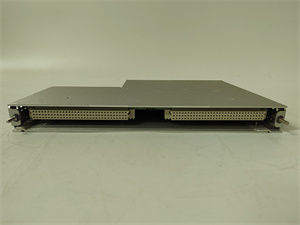

| Product model | 135473-01 |

| Manufacturer | Bently Nevada |

| Product category | Communication Interface Module |

| Series affiliation | 3300 XL Machinery Monitoring System |

| Communication protocol | Modbus RTU/ASCII over RS-485 |

| Interface type | 2-channel RS-485 (isolated) |

| Data transfer rate | 1200 to 115200 baud (configurable) |

| Input compatibility | 135613-02 signal conditioners, 1900/27 controllers |

| Operating voltage | 24 VDC (powered by 125800-01 power supply) |

| Power consumption | 0.8 W typical, 1.2 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 19-inch rack mount (1U height) |

| Dimensions | 44 mm (H) × 483 mm (W) × 120 mm (D) (1.7″ × 19.0″ × 4.7″) |

| Protection features | Isolation (2.5 kV), surge protection, overvoltage protection |

| Compatibility | SCADA systems, HMI panels, 1900/55-0Z-01-01-01 HMIs, PLCs |

| Certification | UL, CE, RoHS compliant |

BENTLY 135473-01

Product introduction

The 135473-01 from Bently Nevada is a specialized communication interface module designed to serve as the data gateway in 3300 XL Machinery Monitoring Systems. This compact module enables seamless connectivity between machinery monitoring components and industrial control networks, translating sensor and conditioner data into standardized Modbus protocol for integration with SCADA systems, HMIs, and PLCs. Bently Nevada’s 135473-01 acts as the critical communication bridge between field-level monitoring equipment like the 135613-02 signal conditioner and higher-level data acquisition systems, ensuring that vibration, position, and machinery health data flows reliably across the industrial network.

Bently Nevada’s 135473-01 addresses the challenge of integrating specialized machinery monitoring equipment into broader industrial control architectures. By converting proprietary sensor data into industry-standard Modbus protocol, it enables centralized monitoring and analysis of critical machinery parameters. Powered by the same 125800-01 power supply that supports other system components, this module maintains the integrity of data generated by calibrated sensors and processed by conditioning modules, ensuring that decision-makers have access to accurate, real-time machinery health information.

Core advantages and technical highlights

Industrial-grade communication reliability: The 135473-01 features isolated RS-485 interfaces with 2.5 kV isolation, protecting sensitive monitoring equipment from ground loops and electrical noise common in industrial environments. This isolation ensures reliable data transmission even in electrically harsh conditions, preserving the integrity of measurements from systems calibrated with tools like the 330130-080-00-00.

Flexible Modbus integration: Supporting both Modbus RTU and ASCII protocols with configurable baud rates (1200 to 115200), the 135473-01 offers versatile integration with virtually all industrial control systems. This flexibility allows it to connect seamlessly with SCADA platforms, PLCs, and HMIs like the 1900/55-0Z-01-01-01, providing system designers with multiple options for data visualization and analysis.

Dual-channel redundancy: Equipped with two independent RS-485 channels, the 135473-01 supports redundant communication architectures, eliminating single points of failure in critical monitoring systems. This redundancy ensures continuous data flow even if one communication path experiences issues, maintaining visibility of machinery health status in mission-critical applications.

Efficient system integration: The module’s compact 1U design and standardized communication protocol simplify integration into existing monitoring systems. It directly interfaces with 135613-02 signal conditioners and 1900/27 controllers, consolidating data from multiple sensors and conditioning channels into a single network interface—reducing wiring complexity and simplifying system expansion.

Typical application scenarios

In power generation facilities, the 135473-01 serves as the communication hub between turbine monitoring systems and plant-wide SCADA networks. It collects processed data from 135613-02 signal conditioners monitoring turbine vibration and position, converting this information into Modbus protocol for transmission to centralized control rooms. The module’s redundant RS-485 channels ensure that critical turbine health data remains available to operators via 1900/55-0Z-01-01-01 HMIs and plant historians, supporting both real-time decision-making and long-term performance analysis.

Oil and gas processing plants utilize the 135473-01 to integrate compressor and pump monitoring systems into facility-wide asset management platforms. By connecting to 135613-02 modules processing signals from 330180-90-05 sensors, it enables remote monitoring of rotating equipment health across distributed processing units. The module’s rugged design and surge protection ensure reliable operation in the harsh electrical environments common in offshore platforms and refineries.

Manufacturing facilities deploy the 135473-01 to connect production line machinery monitoring systems to MES (Manufacturing Execution Systems) and maintenance management platforms. It aggregates vibration and position data from multiple 135613-02 signal conditioners, making this information available to both operational and maintenance teams. This integration supports condition-based maintenance programs by providing centralized access to machinery health data, helping reduce unplanned downtime and optimize maintenance schedules.

BENTLY 135473-01

Related model recommendations

135613-02 (Bently Nevada): Signal conditioner whose data is transmitted via 135473-01.

125800-01 (Bently Nevada): Power supply module that provides 24 VDC to the 135473-01.

1900/27 (Bently Nevada): Controller that communicates with SCADA via 135473-01.

1900/55-0Z-01-01-01 (Bently Nevada): HMI that receives data through 135473-01.

330180-90-05 (Bently Nevada): Proximity sensor whose measurements are transmitted via 135473-01.

330108-91-05 (Bently Nevada): Extension cable in systems connected via 135473-01.

330130-080-00-00 (Bently Nevada): Calibration fixture used with systems incorporating 135473-01.

135473-02 (Bently Nevada): Ethernet-enabled variant of the 135473-01 for IP-based networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 135473-01, verify compatibility with connected devices (typically 135613-02 signal conditioners and SCADA systems). Ensure the mounting rack provides adequate ventilation and is within the 0°C to +60°C operating temperature range. Required tools include a screwdriver set, wire strippers, and a laptop for configuration. Confirm that the 125800-01 power supply can accommodate the module’s power requirements alongside other system components. Inspect the module for shipping damage, checking for loose connectors or damaged pins.

Wiring and configuration: Mount the 135473-01 in the 19-inch rack using provided hardware, ensuring secure installation to prevent vibration-induced connection issues. Connect the 24 VDC power supply from the 125800-01, verifying correct polarity. Wire the module to 135613-02 signal conditioners using shielded twisted-pair cable, ensuring proper shield grounding. Connect the RS-485 outputs to the target SCADA system or HMI, following recommended wiring practices for differential signaling. Use the configuration software to set baud rate, parity, and Modbus address to match system requirements.

Commissioning procedures: After wiring and configuration, power on the system and verify communication links using diagnostic tools. Confirm that data from connected 135613-02 modules appears correctly in the SCADA system or 1900/55-0Z-01-01-01 HMI. Test both communication channels (if using redundancy) by temporarily disconnecting one channel and verifying continued data flow. Perform a functional test by introducing known sensor inputs using the 330130-080-00-00 calibration fixture and confirming accurate data transmission through the 135473-01.

Maintenance suggestions: Conduct quarterly visual inspections of the 135473-01 to check for loose connections, dust accumulation, or signs of overheating. Verify power supply voltage remains within 24 VDC ±1% using a multimeter. Monitor communication link quality periodically, checking for errors or dropped packets in the SCADA system logs. Clean ventilation openings as needed to maintain proper cooling. During scheduled maintenance, verify isolation integrity and surge protection functionality using appropriate test equipment. If communication issues occur, check cable continuity and termination before suspecting module failure.

Service and guarantee commitment

Bently Nevada provides the 135473-01 with a 24-month warranty covering manufacturing defects and component failures under normal operating conditions. Our technical support team offers expert guidance on proper installation, wiring, and configuration, ensuring optimal integration with 135613-02 signal conditioners, 125800-01 power supplies, and SCADA systems.

We offer specialized training on Modbus protocol implementation and industrial communication best practices for systems using the 135473-01. Beyond the warranty period, our service agreements include communication integrity testing, configuration support, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures the 135473-01 delivers reliable data communication throughout its operational lifecycle, backed by our global network of service professionals.