Description

Detailed parameter table

| Parameter name | Parameter value |

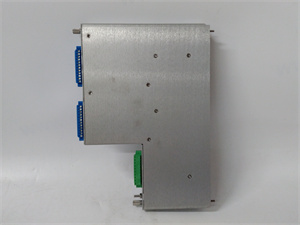

| Product model | 135489-03 |

| Manufacturer | Bently Nevada |

| Product category | Enhanced System Interface Module |

| Series affiliation | 3300 XL Machinery Monitoring System |

| Interface type | 12-channel analog input, 8-channel digital input, 6-channel relay output |

| Analog input range | 0-10 VDC, 4-20 mA (configurable per channel) |

| Digital input type | Dry contact, 24 VDC logic |

| Relay rating | 5 A @ 250 VAC, 5 A @ 30 VDC (resistive load) |

| Communication protocol | Internal system bus, Modbus TCP/IP (integrated), compatible with 135473-01 |

| Operating voltage | 24 VDC (powered by 125800-01 power supply) |

| Power consumption | 4.5 W typical, 6.5 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 19-inch rack mount (2U height) |

| Dimensions | 89 mm (H) × 483 mm (W) × 170 mm (D) (3.5″ × 19.0″ × 6.7″) |

| Protection features | Input isolation, surge protection, overvoltage protection, reverse polarity protection |

| Compatibility | 136188-01 signal input modules, 135473-01 communication modules, 136719-01 expansion modules |

| Certification | UL, CE, RoHS compliant, API 670 compatible |

BENTLY 135489-03

Product introduction

The 135489-03 from Bently Nevada is an enhanced system interface module designed as a centralized control hub in mid-to-large scale 3300 XL Machinery Monitoring Systems. This 2U rack-mount module builds on the capabilities of standard interface modules by offering expanded input/output channels, integrated Ethernet communication, and advanced processing capabilities—serving as the critical nexus between field sensors, expansion modules, and enterprise monitoring systems. Bently Nevada’s 135489-03 acts as the intelligent processing center for machinery health data, aggregating measurements from signal input modules like the 136188-01, enabling localized protection actions, and facilitating seamless data transmission to both local HMIs and remote monitoring platforms.

Bently Nevada’s 135489-03 addresses the complexity of modern industrial monitoring environments where machinery data must be simultaneously analyzed for immediate protection, visualized for operators, and stored for historical trending. Powered by the 125800-01 power supply, it maintains the integrity of calibrated measurements from sensors like the 330180-90-05 while providing enhanced processing to identify subtle fault patterns. Its expanded channel capacity and integrated communication eliminate the need for external network adapters, simplifying system architecture in applications requiring comprehensive monitoring of multiple machinery assets.

Core advantages and technical highlights

Expanded monitoring capacity: The 135489-03 features 12 analog input channels (up from 8 in standard models) that can simultaneously process signals from multiple 136188-01 signal input modules and other conditioning equipment. This expanded capacity allows comprehensive monitoring of complex machinery trains or multiple independent assets from a single interface module, reducing system complexity and cost.

Integrated Ethernet communication: Unlike basic interface modules, the 135489-03 includes built-in Modbus TCP/IP connectivity alongside traditional RS-485, enabling direct connection to industrial Ethernet networks without requiring external communication modules like the 135473-01. This integration simplifies connectivity to SCADA systems, asset management platforms, and cloud-based monitoring solutions.

Advanced processing capabilities: The module incorporates enhanced onboard processing that performs real-time analysis of incoming signals, including peak detection, trend calculation, and alarm condition evaluation. This local processing reduces latency in protection actions while 减轻 the burden on central monitoring systems by pre-processing data before transmission.

Flexible protection configuration: Equipped with 6 programmable relay outputs (expandable to 12 via expansion modules), the 135489-03 supports complex protection logic that can coordinate actions across multiple machinery components. Relay programming includes time-delayed actions, latching/unlatching configurations, and cross-channel interlocks to prevent nuisance trips in complex systems.

Typical application scenarios

In power generation facilities, the 135489-03 serves as the central interface for combined cycle turbine systems, aggregating data from 136188-01 modules monitoring gas turbines, steam turbines, and generators. Its 12 analog inputs process vibration, position, and temperature signals, while digital inputs track operational status (valve positions, load settings). The module’s relays trigger protective actions like alarm annunciators or shutdown sequences, while its Modbus TCP/IP interface streams data to both local 1900/55-0Z-01-01-01 HMIs and plant-wide DCS systems, providing comprehensive visibility to operators and engineers.

Oil and gas processing complexes utilize the 135489-03 to monitor multi-compressor stations, where it integrates with 136719-01 expansion modules to collect data from distributed sensor networks. The module processes signals from 330180-90-05 sensors connected via 330108-91-05 cables, using its advanced processing to detect early-stage bearing faults and surge conditions in centrifugal compressors. Its integrated Ethernet allows secure data transmission to remote monitoring centers, supporting both local protection and centralized asset management.

Manufacturing plants deploy the 135489-03 in production lines with multiple critical assets, where it consolidates monitoring data from motors, gearboxes, and conveyors. The module’s expanded input capacity allows simultaneous monitoring of vibration, temperature, and pressure signals, while its relays coordinate localized alarms and maintenance alerts. By connecting to both MES systems via Ethernet and local HMIs, it provides production teams with real-time machinery health data to optimize throughput and prevent unplanned downtime.

BENTLY 135489-03

Related model recommendations

136188-01 (Bently Nevada): Signal input module whose data is processed by 135489-03.

125800-01 (Bently Nevada): Power supply module that provides 24 VDC to the 135489-03.

135473-01 (Bently Nevada): Legacy communication module for systems requiring RS-485 redundancy.

136719-01 (Bently Nevada): Expansion module that extends the 135489-03‘s monitoring capacity.

330180-90-05 (Bently Nevada): Proximity sensor whose measurements are aggregated by 135489-03.

330130-080-00-00 (Bently Nevada): Calibration fixture used with systems incorporating 135489-03.

1900/55-0Z-01-01-01 (Bently Nevada): HMI that displays processed data from 135489-03.

330108-91-05 (Bently Nevada): Extension cable connecting sensors to systems using 135489-03.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 135489-03, verify compatibility with existing system components including 136188-01 modules and expansion units. Ensure the mounting rack provides adequate ventilation and is within the 0°C to +60°C operating range. Required tools include a screwdriver set, wire strippers, torque wrench, multimeter, and laptop with configuration software. Confirm the 125800-01 power supply can accommodate the module’s power requirements alongside other system components. Inspect the module for shipping damage, focusing on connector integrity and circuit board condition.

Wiring and configuration: Mount the 135489-03 in the 19-inch rack using provided hardware, ensuring secure installation to prevent vibration-induced issues. Connect 24 VDC power from the 125800-01 supply, verifying correct polarity. Wire analog inputs from 136188-01 modules and other signal conditioners using shielded twisted-pair cable, with proper shield grounding at the module end. Connect digital inputs to machinery status sensors and relay outputs to alarm/interlock devices. Configure network parameters for the integrated Ethernet port, setting IP address, subnet mask, and gateway to match facility network requirements.

Commissioning procedures: After wiring, power on the system and verify module initialization via front-panel status indicators. Use configuration software to set input types, scaling, alarm thresholds, and relay logic. Calibrate analog input channels using the 330130-080-00-00 fixture to inject known signals and verify measurement accuracy. Test communication functionality by verifying data transmission to both local HMIs and remote systems via Modbus TCP/IP. Validate protection logic by simulating alarm conditions and confirming proper relay activation. Document all configuration parameters and test results as part of the commissioning record.

Maintenance suggestions: Include the 135489-03 in quarterly preventive maintenance routines, checking for loose connections, dust accumulation, and signs of overheating. Verify power supply voltage remains within 24 VDC ±1% using a calibrated multimeter. Test relay operation periodically by activating manual test functions and confirming contact operation with a continuity tester. Inspect Ethernet connectivity by checking network link status and reviewing communication logs for errors. During scheduled shutdowns, recalibrate analog input channels and verify alarm setpoints. Clean ventilation openings to maintain proper cooling and prevent thermal degradation.

Service and guarantee commitment

Bently Nevada provides the 135489-03 with a 30-month warranty covering manufacturing defects and component failures under normal operating conditions—the longest in its product class. Our technical support team offers specialized guidance on system integration, advanced relay logic programming, and network configuration to maximize the module’s capabilities with 136188-01 signal input modules and other system components.

We offer comprehensive training programs on the 135489-03‘s advanced features, including Ethernet integration, complex alarm logic, and system expansion strategies. Beyond the warranty period, our service agreements include priority technical support, calibration verification, performance testing, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures the 135489-03 delivers reliable system interface functionality throughout its operational lifecycle, backed by our global network of service professionals and application engineers.