Description

Detailed parameter table

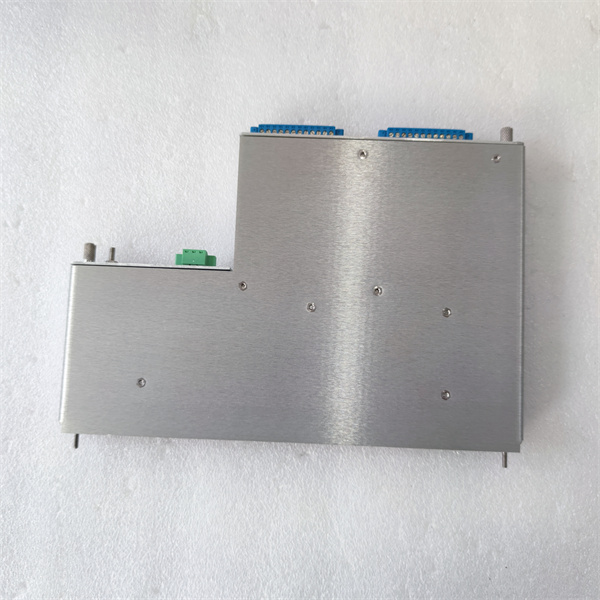

| Parameter name | Parameter value |

| Product model | 135489-04 |

| Manufacturer | Bently Nevada |

| Product category | System Interface Module |

| Series affiliation | 3300 XL Machinery Monitoring System |

| Interface type | 8-channel analog input, 4-channel relay output |

| Input range | 0-10 VDC, 4-20 mA (configurable per channel) |

| Relay rating | 5 A @ 250 VAC, 5 A @ 30 VDC (resistive load) |

| Communication protocol | Internal system bus, compatible with 135473-01 Modbus gateway |

| Operating voltage | 24 VDC (powered by 125800-01 power supply) |

| Power consumption | 3.5 W typical, 5.0 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 19-inch rack mount (2U height) |

| Dimensions | 89 mm (H) × 483 mm (W) × 160 mm (D) (3.5″ × 19.0″ × 6.3″) |

| Protection features | Input isolation, overvoltage protection, short circuit protection |

| Compatibility | 135613-02 signal conditioners, 135473-01 communication modules, 1900/27 controllers |

| Certification | UL, CE, RoHS compliant |

BENTLY 135489-04

Product introduction

The 135489-04 from Bently Nevada is a versatile system interface module designed as a central aggregation point in 3300 XL Machinery Monitoring Systems. This 2U rack-mount module combines analog signal acquisition with programmable relay outputs, serving as the critical link between sensor conditioning equipment and both local protection systems and remote monitoring networks. Bently Nevada’s 135489-04 acts as the operational hub of machinery protection systems, collecting processed sensor data, enabling local alarm functionality, and providing a standardized interface to communication modules like the 135473-01 for integration with broader industrial control systems.

Bently Nevada’s 135489-04 addresses the need for centralized signal management in complex monitoring applications, where data from multiple sensors must be aggregated, processed, and distributed to both protection relays and data acquisition systems. Powered by the 125800-01 power supply, this module maintains the integrity of measurements from calibrated sensors while providing configurable alarm logic to trigger protective actions—ensuring both comprehensive monitoring and reliable machinery protection. Its flexible design makes it suitable for everything from simple machine protection systems to complex multi-point monitoring architectures.

Core advantages and technical highlights

Flexible signal aggregation: The 135489-04 features 8 configurable analog input channels that accept both voltage (0-10 VDC) and current (4-20 mA) signals from 135613-02 signal conditioners and other monitoring equipment. This flexibility allows it to consolidate data from various sensor types, creating a centralized collection point for machinery health parameters measured by calibrated systems using tools like the 330130-080-00-00.

Integrated protection capability: Equipped with 4 programmable relay outputs, the module provides local protection functionality that can trigger alarms or shutdown sequences without relying on external systems. This critical capability ensures rapid response to machinery faults, with relay logic configurable to respond to specific threshold crossings in the input signals from 330180-90-05 sensors and other monitoring devices.

Dual-path data distribution: The 135489-04 simultaneously supports local protection actions through its relay outputs and data transmission to higher-level systems via integration with 135473-01 communication modules. This dual functionality ensures that critical machinery health data is both used for immediate protection and made available for long-term analysis, supporting both operational safety and predictive maintenance programs.

Industrial-grade reliability: Built with input isolation and comprehensive protection features, the module maintains performance in harsh industrial environments. Its rugged construction ensures reliable operation across a 0°C to +60°C temperature range, while overvoltage and short circuit protection safeguards both the module and connected equipment from electrical anomalies.

Typical application scenarios

In power generation facilities, the 135489-04 serves as the central interface for turbine and generator monitoring systems, collecting vibration and position data from multiple 135613-02 signal conditioners. Its relay outputs are configured to trigger alarms or protective shutdowns when measurements exceed critical thresholds, while simultaneously transmitting data to the 135473-01 module for integration with plant SCADA systems. This configuration provides both immediate machinery protection and visibility to control room operators via 1900/55-0Z-01-01-01 HMIs, enhancing both safety and operational awareness.

Oil and gas processing plants utilize the 135489-04 in compressor train monitoring systems, aggregating data from 330180-90-05 sensors connected through 330108-91-05 cables and signal conditioners. The module’s relays are programmed to activate local alarm annunciators and safety interlocks during abnormal conditions, while its integration with the 135473-01 ensures this data is available to centralized asset management platforms. This setup enables both immediate fault response and remote monitoring of distributed compressor stations.

Manufacturing facilities deploy the 135489-04 to monitor production line machinery, collecting vibration data from motors, pumps, and gearboxes across multiple production cells. The module consolidates this information, triggering maintenance alerts through its relay outputs when early fault indicators are detected, while simultaneously sending data to MES systems via the 135473-01 communication module. This integration supports condition-based maintenance by providing both real-time alerts and historical trend data for analysis.

BENTLY 135489-04

Related model recommendations

135473-01 (Bently Nevada): Communication module that transmits data from 135489-04 to SCADA systems.

135613-02 (Bently Nevada): Signal conditioner whose outputs connect to 135489-04 inputs.

125800-01 (Bently Nevada): Power supply module that provides 24 VDC to the 135489-04.

1900/27 (Bently Nevada): Controller that interfaces with 135489-04 for advanced monitoring.

330180-90-05 (Bently Nevada): Proximity sensor whose measurements are processed by 135489-04.

330130-080-00-00 (Bently Nevada): Calibration fixture used with systems incorporating 135489-04.

1900/55-0Z-01-01-01 (Bently Nevada): HMI that displays data from the 135489-04 module.

330108-91-05 (Bently Nevada): Extension cable in sensor systems connected to 135489-04.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 135489-04, verify compatibility with connected signal conditioners and communication modules. Ensure the mounting rack provides adequate ventilation and is within the 0°C to +60°C operating temperature range. Required tools include a screwdriver set, wire strippers, multimeter, and laptop for configuration. Confirm that the 125800-01 power supply can accommodate the module’s power requirements alongside other system components. Inspect the module for shipping damage, checking for loose connectors or damaged terminals.

Wiring and configuration: Mount the 135489-04 in the 19-inch rack using provided hardware, ensuring secure installation. Connect the 24 VDC power supply from the 125800-01, verifying correct polarity. Wire analog inputs from 135613-02 signal conditioners using shielded twisted-pair cable, ensuring proper shield grounding. Connect relay outputs to alarm devices or interlock systems, following appropriate wiring practices for power circuits. Establish communication with the 135473-01 module using the internal system bus. Use configuration software to set input types, scaling, and relay logic parameters.

Commissioning procedures: After wiring and configuration, power on the system and verify proper operation of all input channels using known signals from the 330130-080-00-00 calibration fixture. Test relay functionality by simulating threshold crossings and confirming proper activation/deactivation. Verify communication with the 135473-01 module by checking data transmission to SCADA systems or 1900/55-0Z-01-01-01 HMIs. Document all configuration parameters and test results as part of the commissioning record.

Maintenance suggestions: Conduct quarterly visual inspections of the 135489-04 to check for loose connections, dust accumulation, or signs of overheating. Verify power supply voltage remains within 24 VDC ±1% using a multimeter. Test relay operation periodically by triggering manual test functions and confirming proper contact operation. During scheduled maintenance, recalibrate input channels using known reference signals to ensure measurement accuracy. Clean ventilation openings as needed to maintain proper cooling. If input signal issues occur, check connections to 135613-02 modules before suspecting module failure.

Service and guarantee commitment

Bently Nevada provides the 135489-04 with a 24-month warranty covering manufacturing defects and component failures under normal operating conditions. Our technical support team offers expert guidance on proper installation, wiring, configuration, and integration with 135473-01 communication modules, 135613-02 signal conditioners, and 125800-01 power supplies.

We offer specialized training on system configuration, relay logic programming, and integration best practices for systems using the 135489-04. Beyond the warranty period, our service agreements include calibration verification, performance testing, configuration support, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures the 135489-04 delivers reliable system interface functionality throughout its operational lifecycle, backed by our global network of service professionals.