Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 136719-01 |

| Manufacturer | Bently Nevada |

| Product category | Expansion Interface Module |

| Series affiliation | 3300 XL Machinery Monitoring System |

| Interface type | 16-channel analog input, 8-channel digital input, 4-channel relay output |

| Analog input range | 0-10 VDC, 4-20 mA (configurable per channel) |

| Digital input type | Dry contact, 24 VDC logic |

| Relay rating | 5 A @ 250 VAC, 5 A @ 30 VDC (resistive load) |

| Communication protocol | Internal system bus, compatible with 135489-04 interface modules |

| Operating voltage | 24 VDC (powered by 125800-01 power supply) |

| Power consumption | 5.0 W typical, 7.5 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

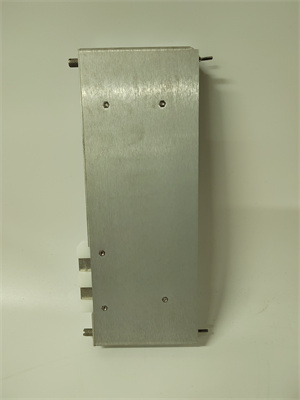

| Form factor | 19-inch rack mount (3U height) |

| Dimensions | 133 mm (H) × 483 mm (W) × 180 mm (D) (5.2″ × 19.0″ × 7.1″) |

| Protection features | Channel isolation, surge protection, overvoltage protection |

| Compatibility | 135489-04 system interfaces, 135613-02 signal conditioners, 135473-01 communication modules |

| Certification | UL, CE, RoHS compliant |

BENTLY 136719-01

Product introduction

The 136719-01 from Bently Nevada is a high-capacity expansion interface module designed to extend the monitoring capabilities of 3300 XL Machinery Monitoring Systems. This 3U rack-mount module provides additional analog and digital input channels alongside programmable relay outputs, enabling scalable system expansion for complex machinery monitoring applications. Bently Nevada’s 136719-01 serves as a flexible extension to core interface modules like the 135489-04, allowing system designers to accommodate more sensors and monitoring points without compromising performance or reliability.

Bently Nevada’s 136719-01 addresses the challenge of scaling monitoring systems in large industrial facilities where multiple machinery assets require comprehensive monitoring. By providing 16 analog inputs, it can aggregate data from additional 135613-02 signal conditioners connected to sensors like the 330180-90-05, while its digital inputs capture discrete machinery status signals. Powered by the 125800-01 power supply and integrated with communication modules via the 135489-04, this expansion module ensures that extended monitoring networks maintain the same data integrity and protection capabilities as the core system.

Core advantages and technical highlights

Scalable monitoring capacity: The 136719-01 features 16 configurable analog input channels that expand the system’s ability to monitor additional sensors beyond the capacity of the 135489-04 base module. This scalability allows monitoring systems to grow alongside facility needs, accommodating new machinery or additional measurement points on existing equipment while maintaining centralized data collection.

Hybrid signal acquisition: Combining analog and digital inputs, the module captures both continuous vibration/position data from 330180-90-05 sensors and discrete status signals (like valve positions or motor run status) from machinery. This hybrid capability provides a more complete picture of machinery health and operational status, enhancing diagnostic capabilities.

Integrated expansion architecture: Designed to work seamlessly with 135489-04 system interface modules via the internal system bus, the 136719-01 ensures that expanded systems maintain unified data flow and protection logic. This integration eliminates communication bottlenecks between base and expansion modules, ensuring consistent performance across the entire monitoring network.

Enhanced protection functionality: Equipped with 4 programmable relay outputs, the module extends the system’s protective action capabilities to new monitoring points. Relay logic can be configured to respond to both local input conditions and signals from the core 135489-04 module, enabling coordinated protection strategies across extended machinery trains.

Typical application scenarios

In large power generation facilities, the 136719-01 expands turbine monitoring systems by adding channels for auxiliary equipment like pumps, fans, and lube oil systems. Connected to the core 135489-04 module, it aggregates data from additional 135613-02 signal conditioners monitoring these secondary assets, while its digital inputs track equipment status signals. The module’s relays are configured to trigger localized alarms or interlocks for auxiliary systems, while data flows through the 135473-01 to plant SCADA for comprehensive visibility.

Oil and gas processing complexes utilize the 136719-01 to extend monitoring coverage across multiple compressor units or pump stations. Each expansion module monitors a dedicated machinery train, with analog inputs connected to 330180-90-05 sensors via 330108-91-05 cables and signal conditioners, and digital inputs tracking operational status. Integrated with the core 135489-04 system, these expansion modules create a unified monitoring network that provides both localized protection and centralized data analysis.

Manufacturing plants deploy the 136719-01 to expand monitoring systems across production lines, adding capacity to monitor additional motors, gearboxes, and conveyors. The module’s analog channels capture vibration data from these assets, while digital inputs track production line status signals. By integrating with the core system via the 135489-04, it ensures that expanded production monitoring maintains consistent data quality and alarm response, supporting facility-wide condition-based maintenance programs.

BENTLY 136719-01

Related model recommendations

135489-04 (Bently Nevada): System interface module that integrates with 136719-01 for expanded systems.

135613-02 (Bently Nevada): Signal conditioner whose outputs connect to 136719-01 analog inputs.

125800-01 (Bently Nevada): Power supply module that provides 24 VDC to the 136719-01.

135473-01 (Bently Nevada): Communication module that transmits aggregated data from expanded systems.

330180-90-05 (Bently Nevada): Proximity sensor whose measurements are processed by 136719-01.

330130-080-00-00 (Bently Nevada): Calibration fixture used with expanded systems incorporating 136719-01.

1900/27 (Bently Nevada): Controller that interfaces with expanded systems via 136719-01.

330108-91-05 (Bently Nevada): Extension cable in sensor systems connected to 136719-01.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 136719-01, verify compatibility with the core 135489-04 module and ensure the mounting rack has sufficient space and ventilation. Confirm the operating environment is within the 0°C to +60°C range. Required tools include a screwdriver set, wire strippers, multimeter, and laptop with configuration software. Check that the 125800-01 power supply can accommodate the additional load from the expansion module. Inspect the module for shipping damage, particularly focusing on connector integrity.

Wiring and integration: Mount the 136719-01 in the 19-inch rack adjacent to the 135489-04 module using provided hardware. Connect the 24 VDC power supply from the 125800-01, ensuring proper polarity. Establish communication with the core system using the internal system bus cable between 136719-01 and 135489-04. Wire analog inputs from additional 135613-02 signal conditioners using shielded twisted-pair cable, with proper shield grounding. Connect digital inputs to machinery status sensors and relay outputs to alarm or interlock devices.

Configuration and commissioning: Use system configuration software to integrate the 136719-01 with the core 135489-04 system, assigning input types, scaling, and addressing. Program relay logic to coordinate with both local inputs and signals from the core system. Verify all analog channels using the 330130-080-00-00 calibration fixture to ensure measurement accuracy. Test digital input functionality by activating connected status sensors and confirming proper detection. Verify communication with the core system and data transmission through the 135473-01 module to SCADA/HMI systems.

Maintenance suggestions: Include the 136719-01 in quarterly visual inspection routines, checking for loose connections, dust accumulation, and signs of overheating. Verify power supply voltage remains within 24 VDC ±1% during each inspection. Test relay operation periodically by triggering manual test functions. During scheduled maintenance, recalibrate analog input channels using known reference signals. Clean ventilation openings to maintain proper cooling. When troubleshooting system issues, verify communication with the 135489-04 before isolating problems to the expansion module.

Service and guarantee commitment

Bently Nevada provides the 136719-01 with a 24-month warranty covering manufacturing defects and component failures under normal operating conditions. Our technical support team offers expert guidance on proper installation, integration with 135489-04 systems, configuration, and troubleshooting of expanded monitoring networks.

We offer specialized training on system expansion strategies, configuration of hybrid input systems, and integration best practices for the 136719-01. Beyond the warranty period, our service agreements include calibration verification, performance testing, and expedited replacement services to minimize downtime in expanded systems. Bently Nevada’s commitment to quality ensures the 136719-01 delivers reliable expansion capabilities throughout its operational lifecycle, backed by our global network of service professionals.