Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 138607-01 (standard variant of 3500/22M) |

| Manufacturer | Bently Nevada |

| Product category | Industrial Grade Power Supply Module |

| Series affiliation | 3500 Machinery Protection System |

| Output voltage | 5 VDC (3 A), ±15 VDC (1 A each) |

| Input voltage range | 100-240 VAC (50/60 Hz) or 18-32 VDC |

| Maximum power rating | 30 W |

| Efficiency | >85% at full load |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Enhanced features | Reinforced connectors, industrial-grade thermal management |

| Protection mechanisms | Overvoltage, overcurrent, and short circuit protection |

| Redundancy support | N+1 redundant configuration capability |

| Compatibility | All 3500 series modules, including 3500/15, 3500/61, 127610-01 |

| Certifications | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Diagnostic features | Power status LEDs, voltage monitoring, fault reporting via system bus |

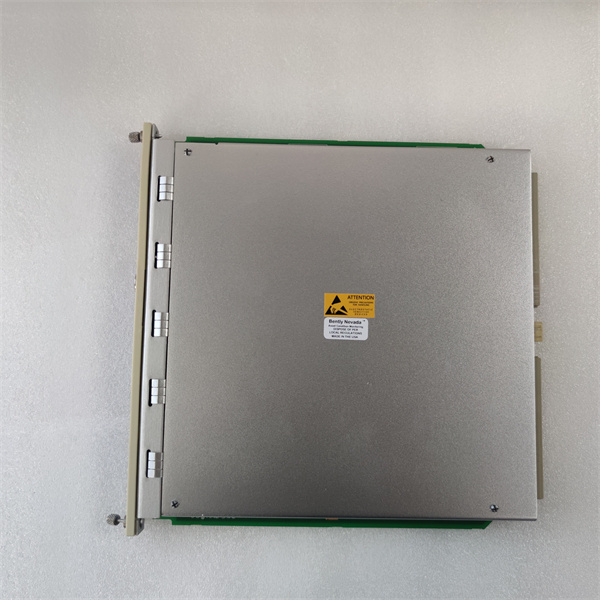

BENTLY 138607-01

Product introduction

The 138607-01 from Bently Nevada is the standard industrial-grade variant of the 3500/22M power supply module, serving as the reliable energy source for 3500 Machinery Protection Systems. This specifically engineered unit delivers stable, regulated power to all critical components within the 3500 ecosystem, from sensor modules to protective relays like the 127610-01 assembly. As the production-standard implementation of the 3500/22M platform, the 138607-01 incorporates hardware optimizations that make it the default choice for industrial machinery protection applications requiring uncompromising reliability.

Bently Nevada’s 138607-01 builds upon the core design of the 3500/22M with enhancements tailored for harsh industrial environments. Its robust construction ensures consistent performance in vibration-prone settings, while specialized thermal management allows extended operation at maximum load—critical for protection systems where power interruptions could lead to equipment damage or safety incidents. This variant forms the power backbone of countless 3500 installations across power generation, oil and gas, and manufacturing sectors.

Core advantages and technical highlights

Industrialized construction

The 138607-01 features reinforced connectors with enhanced vibration resistance, ensuring secure electrical connections in machinery environments where constant vibration could loosen standard connectors. This mechanical robustness prevents intermittent power issues that might compromise protection system operation.

Enhanced thermal management

This variant incorporates upgraded heat dissipation components that maintain stable operation at full 30W load across the entire 0°C to +60°C operating range. The improved thermal design prevents performance degradation during extended high-temperature operation, a critical advantage in unconditioned industrial spaces.

Factory-calibrated precision

Each 138607-01 undergoes rigorous factory calibration to ensure voltage regulation within tight tolerances (±2% for 5 VDC, ±3% for ±15 VDC) throughout its operational lifecycle. This calibration ensures consistent power delivery to sensitive components like 3500/61 displays and measurement modules, maintaining system accuracy over time.

Seamless system integration

As the standard 3500/22M variant, the 138607-01 offers plug-and-play compatibility with all 3500 series components. Its standardized rack-mount design fits perfectly into 3500/20 system racks, enabling straightforward integration into new installations or existing system upgrades.

Application focus

Critical power generation systems

In turbine and generator protection applications, the 138607-01 provides the stable power required for continuous monitoring by vibration sensors and temperature transmitters. Its ability to maintain regulation during voltage fluctuations ensures protection relays like the 127610-01 remain operational during grid disturbances common in power generation facilities.

Harsh environment installations

Oil and gas compressor stations and pipeline facilities benefit from the 138607-01‘s rugged design, which withstands the electrical noise, temperature extremes, and mechanical vibration typical in these environments. Its dual input capability allows operation from either AC mains or 24 VDC control systems common in hazardous areas.

High-availability manufacturing systems

Production facilities rely on the 138607-01 for powering machinery protection systems monitoring critical production equipment. Its redundancy capability enables N+1 configurations that prevent unplanned downtime due to power supply failures, supporting continuous manufacturing operations.

BENTLY 138607-01

Integration ecosystem

The 138607-01 serves as the power foundation for key 3500 components:

3500/15 relay modules containing 127610-01 relay assemblies

3500/61 display modules requiring stable power for accurate visualization

3500/34 communication gateways for data transmission

125720-01 temperature transmitters and 135137-01 input modules

3500/70M reciprocating machinery monitors

Its reliable power delivery ensures all these components work in harmony to provide comprehensive machinery protection.

Installation and maintenance

Installation guidelines

Mount the 138607-01 in the lower section of 3500/20 racks to optimize power distribution. For redundant configurations, install multiple units with separate input power sources to ensure fault tolerance. Use 18-22 AWG wiring for input connections and ensure proper grounding to minimize electrical noise.

Maintenance recommendations

Perform quarterly visual inspections to verify status LEDs indicate normal operation. Measure output voltages annually using calibrated equipment to confirm regulation remains within specifications. Clean ventilation openings regularly to maintain thermal performance. In redundant systems, test failover capability semi-annually by temporarily isolating one unit.

Service and warranty

The 138607-01 is covered by Bently Nevada’s 36-month warranty, which guarantees manufacturing quality and performance under normal operating conditions. This warranty includes coverage for voltage regulation accuracy, protection features, and mechanical integrity. Technical support is available for installation assistance, redundancy configuration, and troubleshooting. Extended service agreements provide additional coverage for preventive maintenance, calibration verification, and expedited replacement to ensure maximum system availability.