Description

Detailed parameter table

| Parameter name | Parameter value |

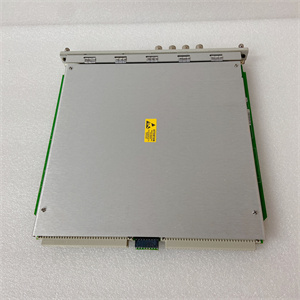

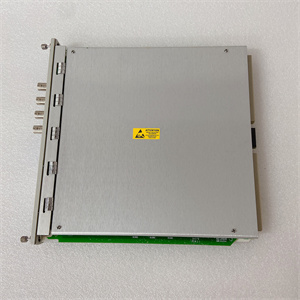

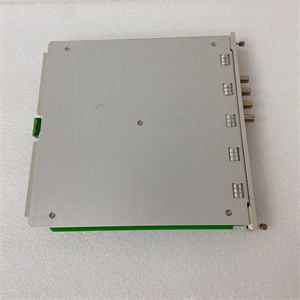

| Product model | 140734-01 (variant of 3500/40M) |

| Manufacturer | Bently Nevada |

| Product category | Industrial Communication Gateway Module |

| Communication ports | 2× Ethernet (10/100BASE-T), 1× RS-485, 1× USB service port |

| Supported protocols | Modbus TCP/IP, OPC DA, Bently Nevada proprietary protocol |

| Data transfer rate | Up to 100 Mbps |

| Maximum connected nodes | 32 devices in distributed configurations |

| Operating voltage | 5 VDC, ±15 VDC (from 3500 system power supply) |

| Power consumption | 7 W typical, 9 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Protection features | Network isolation, surge protection, redundant communication support |

| Compatibility | 3500/60 163179-01 displays, 176449-01 cables, all 3500 monitors |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 140734-01

Product introduction

The 140734-01 from Bently Nevada is the production variant of the 3500/40M communication gateway, serving as the critical data distribution hub within 3500 Machinery Protection Systems. This precision-engineered module acts as the connectivity backbone that links machinery sensors, monitoring modules, and visualization systems, ensuring seamless data flow throughout industrial automation architectures. As the standardized implementation of the 3500/40M platform, 140734-01 aggregates critical health data from sensors connected via 176449-01 cables and distributes it to operational decision-makers through interfaces like the 3500/60 163179-01 display module.

Bently Nevada’s 140734-01 addresses the fundamental need for reliable industrial communication in safety-critical monitoring applications. Its robust design ensures that vibration, temperature, and position data maintain integrity during transmission, while its multi-protocol support enables integration with both specialized machinery health systems and general-purpose automation platforms. By serving as the central communication node, 140734-01 ensures that critical machinery information is available to operators, maintenance teams, and enterprise systems exactly when and where it is needed.

Core advantages and technical highlights

Industrial-grade communication reliability: The 140734-01 features enhanced signal processing that maintains data integrity even in electrically noisy industrial environments. Its network isolation and surge protection mechanisms shield sensitive communication circuits from power disturbances and electromagnetic interference, ensuring uninterrupted data transmission between field sensors and 3500/60 163179-01 displays.

Dual-protocol flexibility: Supporting both Modbus TCP/IP and OPC DA protocols, 140734-01 enables seamless data exchange with diverse industrial systems. This dual capability allows the module to simultaneously feed real-time data to SCADA systems for operational control and to asset management software for predictive maintenance analysis, eliminating the need for separate communication pathways.

Redundant data pathways: Equipped with two independent Ethernet ports with automatic failover, 140734-01 guarantees continuous communication even during network outages. This redundancy is particularly valuable for safety-critical applications where communication interruptions could delay detection of machinery issues, ensuring protection system data always reaches monitoring personnel via 3500/60 163179-01 displays.

Optimized data management: The module implements intelligent filtering and prioritization that ensures time-sensitive alarm data receives transmission priority over historical trending information. This selective handling optimizes network bandwidth while guaranteeing that critical alerts reach operators without delay, supporting timely intervention in potential machinery failure scenarios.

Typical application scenarios

In power generation facilities, 140734-01 serves as the communication nerve center for turbine and generator protection systems. It collects vibration data from sensors connected via 176449-01 cables across multiple units, then distributes this information to local 3500/60 163179-01 displays for immediate operator visibility and to plant historians via Modbus TCP/IP for long-term performance analysis. This dual distribution ensures both real-time protection and historical trending capabilities are maintained simultaneously.

Oil and gas compressor stations utilize 140734-01 to connect geographically dispersed monitoring systems to central control rooms. The module aggregates data from remote 3500/70M monitors, transmitting critical machinery health information through redundant pathways to both on-site 3500/60 163179-01 displays and enterprise SCADA systems. Its robust design ensures reliable communication even in remote locations with harsh environmental conditions and challenging network infrastructure.

Manufacturing plants deploy 140734-01 to create unified visibility across diverse production line machinery. The module consolidates data from pumps, motors, and gearboxes throughout the facility, making this information available to maintenance teams via shop-floor 3500/60 163179-01 displays while simultaneously feeding OPC DA data to production management systems. This integration supports both machinery protection and process optimization initiatives.

BENTLY 140734-01

Related model recommendations

3500/40M: Base communication gateway platform that incorporates the 140734-01 variant.

3500/60 163179-01: Display module that visualizes data distributed by 140734-01.

176449-01: Sensor cable providing input data to systems connected through 140734-01.

3500/22M: Power supply module that provides operating power to 140734-01.

3500/70M: Reciprocating machinery monitor whose data is aggregated by 140734-01.

3500/15: Relay module whose status is transmitted through 140734-01.

125720-01: Temperature transmitter integrated into data streams via 140734-01.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 140734-01, verify compatibility with existing 3500 system components and ensure the 3500/20 rack has an available slot. Confirm the system power supply can support the additional load. Gather required tools including torque screwdrivers, network cable testers, and configuration laptops. Inspect the module for shipping damage, paying particular attention to Ethernet ports and backplane connectors. Plan network topology in advance, especially for redundant configurations requiring separate paths to 3500/60 163179-01 displays.

Maintenance suggestions: Include 140734-01 in quarterly maintenance checks, verifying status LEDs indicate normal operation and confirming network link integrity. Review communication logs regularly to identify potential issues like packet loss or connection interruptions. Test redundant failover functionality semi-annually by isolating primary network connections and verifying automatic switchover. Keep firmware updated during scheduled maintenance windows. Clean ventilation openings periodically to prevent thermal issues and ensure reliable operation in control cabinet environments.

Service and guarantee commitment

Bently Nevada provides 140734-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions. This warranty includes coverage for communication reliability, protocol functionality, and mechanical integrity. Our technical support team offers expert assistance with network configuration, protocol implementation, and integration with 3500/60 163179-01 displays and other system components.

We provide specialized training on gateway operation, redundancy management, and troubleshooting specific to 140734-01. Beyond the warranty period, our service agreements include technical support, firmware updates, and expedited replacement options to minimize downtime. Bently Nevada’s commitment to quality ensures 140734-01 delivers reliable communication performance throughout its operational lifecycle, backed by our global service network.