Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 140734-02 (specific variant of 3500/42M) |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Vibration Monitor |

| Channel configuration | 4 independent monitoring channels |

| Measurement type | Radial vibration, axial position, differential expansion |

| Frequency range | 0.1 Hz to 10 kHz |

| Sampling rate | 256 samples per second per channel (continuous), 12,800 sps (transient) |

| Accuracy | ±0.2% of full scale |

| Alarm capability | Configurable dual alarm levels per channel (Alert, Danger) |

| Communication support | Integrated data communication for network integration |

| Operating voltage | 5 VDC, ±15 VDC (from 125744-02 rack backplane) |

| Power consumption | 8 W typical, 10 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

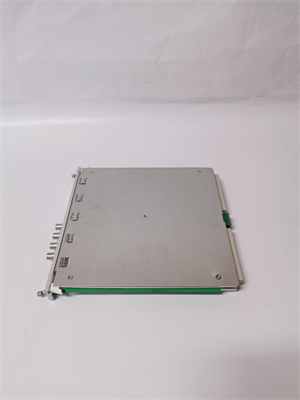

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 125744-02 racks, 1900/65A-01-02-01-00-00 monitors, 136711-01 cables |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 140734-02

Product introduction

The 140734-02 from Bently Nevada is a high-performance vibration monitoring module and a specific variant of the 3500/42M series, serving as a core measurement component in 3500 Machinery Protection Systems. This 2-slot module is uniquely positioned to combine precise machinery parameter monitoring with enhanced communication capabilities, making it a critical data hub in industrial monitoring architectures. Unlike standard monitoring modules, 140734-02 emphasizes seamless data integration across plant-wide systems while maintaining the measurement accuracy that defines the 3500 series.

Bently Nevada’s 140734-02 acts as the vital interface between sensor inputs and both local protection logic and enterprise-level maintenance systems. It converts raw signals from proximity probes, vibration sensors, and expansion transducers (connected via 136711-01 cables) into actionable machinery health metrics. Installed in 125744-02 racks and configured through 136180-01 modules, it provides real-time protection through configurable alarms while enabling data sharing with complementary systems like the 1900/65A-01-02-01-00-00 for distributed monitoring setups. This module is particularly valued in applications requiring both centralized protection and decentralized data access across multiple operational areas.

Core advantages and technical highlights

Enhanced communication architecture: A defining feature of 140734-02 is its robust integrated communication capabilities, which enable seamless data transmission to both local display modules and remote enterprise systems. This architecture facilitates integrated monitoring networks where critical vibration data can be shared with distributed 1900/65A-01-02-01-00-00 monitors, providing consistent visibility across plant operations. The module supports standardized industrial protocols, ensuring compatibility with diverse SCADA and asset management systems.

Precision measurement technology: 140734-02 delivers exceptional measurement accuracy of ±0.2% full scale across its four channels, supporting radial vibration, axial position, and differential expansion measurements. Its 0.1 Hz to 10 kHz frequency range ensures capture of both low-frequency positional changes (critical for thrust bearing monitoring) and high-frequency vibration components (essential for detecting early-stage bearing defects), providing comprehensive machinery health assessment.

Configurable protection strategies: Each channel features independently programmable dual alarm levels (Alert and Danger) with adjustable time delays and latching behavior. This flexibility allows customization of protection logic to match specific machinery types and operational requirements, balancing protection sensitivity with operational availability. Alarm parameters can be easily configured through 136180-01 modules to implement consistent protection philosophies across plant-wide systems.

Seamless ecosystem integration: The module maintains full compatibility with key 3500 series components, including 125744-02 racks, 133388-01 transient monitors, and 3500/60 163179-01 display modules. Its communication capabilities extend this integration to 1900 series devices, enabling hybrid monitoring architectures that combine the advanced protection capabilities of 3500 systems with the distributed monitoring flexibility of 1900 series devices.

Typical application scenarios

Multi-plant manufacturing facilities

In large manufacturing complexes with multiple production areas, 140734-02 modules installed in central equipment racks monitor critical rotating machinery such as main drive motors, precision gearboxes, and hydraulic pumps. Their enhanced communication capabilities allow vibration data to be transmitted to distributed 1900/65A-01-02-01-00-00 monitors located in area control rooms, providing localized visibility while maintaining centralized protection logic. This setup ensures maintenance teams in different plant sections have access to relevant machinery health data without compromising the integrity of the core protection system.

Integrated power generation facilities

Power plants utilize 140734-02 modules to monitor turbine-generator sets, capturing vibration data from bearings, axial thrust position, and rotor expansion. The module integrates with plant-wide SCADA systems through its communication interface, while sharing critical measurements with 1900/65A-01-02-01-00-00 monitors in auxiliary control areas. This configuration enables both turbine specialists in central control rooms and auxiliary operators in local control areas to access relevant machinery health information, supporting coordinated maintenance decisions and operational efficiency.

Petrochemical processing complexes

In refinery operations, 140734-02 modules monitor compressor trains, pump stations, and turbine drivers, with their communication features enabling data aggregation into refinery-wide asset management systems. The modules share key vibration metrics with 1900/65A-01-02-01-00-00 monitors located in process unit control rooms, allowing process operators to correlate vibration trends with process conditions. This integration helps distinguish between genuine machinery faults and process-induced vibrations, reducing false alarms while ensuring timely response to critical mechanical issues.

BENTLY 140734-02

Related model recommendations

3500/42M: Base vibration monitoring series that includes the 140734-02 variant.

125744-02: Rack assembly that houses and powers the 140734-02 module.

136180-01: Configuration module for programming monitoring parameters and alarm logic.

1900/65A-01-02-01-00-00: Distributed monitor for localized visualization of shared data.

136711-01: Shielded sensor cable for connecting proximity probes and vibration sensors.

133388-01: Transient monitor for high-speed data capture during alarm conditions.

3500/60 163179-01: Central display module for visualizing data from multiple 3500 modules.

123M4610: USB cable for local configuration and data retrieval.

Installation, commissioning and maintenance instructions

Installation

Before installing 140734-02, verify compatibility with the target 125744-02 rack firmware version and ensure two adjacent slots are available. Confirm the rack power supply can accommodate the 10 W maximum load. Mount the module securely in the rack, ensuring proper backplane connection. Connect sensors using shielded 136711-01 cables, following polarity markings and torque specifications (0.5-0.6 N·m). Establish communication links to enterprise systems and any connected 1900/65A-01-02-01-00-00 monitors, ensuring proper network addressing and protocol configuration.

Commissioning

After installation, configure the module using 136180-01 configuration tools or direct USB connection with 123M4610 cables. Set input types, measurement ranges, and alarm thresholds based on machinery specifications and protection requirements. Establish communication parameters to ensure seamless data sharing with distributed systems. Verify measurement accuracy using calibrated test signals (50 mV/g for accelerometers, 8 mV/mil for proximity probes). Confirm alarm functionality by simulating abnormal conditions and verifying both local and remote alarm indication. Synchronize time settings with other system components to ensure consistent data timestamps across the monitoring network.

Maintenance

Include 140734-02 in quarterly system inspections, verifying status LEDs indicate normal operation, communication links are active, and backplane connections are secure. Perform annual calibration using certified vibration standards to maintain measurement accuracy. Check data transmission integrity to connected systems, including 1900/65A-01-02-01-00-00 monitors, ensuring consistent data flow and no packet loss. Download and archive trend data monthly to support predictive maintenance analysis. Update firmware during scheduled system upgrades to maintain compatibility with the latest configuration tools and communication protocols, following Bently Nevada’s recommended update procedures.

Service and guarantee commitment

Bently Nevada provides the 140734-02 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, communication functionality, and component reliability. Our technical support team offers specialized guidance on system integration, including optimal configuration for communication with 1900/65A-01-02-01-00-00 monitors and enterprise systems.

We offer comprehensive training on module programming, communication setup, and diagnostic interpretation specific to 140734-02. Beyond the warranty period, our service agreements include calibration verification, technical support, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures reliable performance throughout the module’s operational lifecycle, backed by our global network of service professionals available 24/7 for critical support needs.