Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 146031-02 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

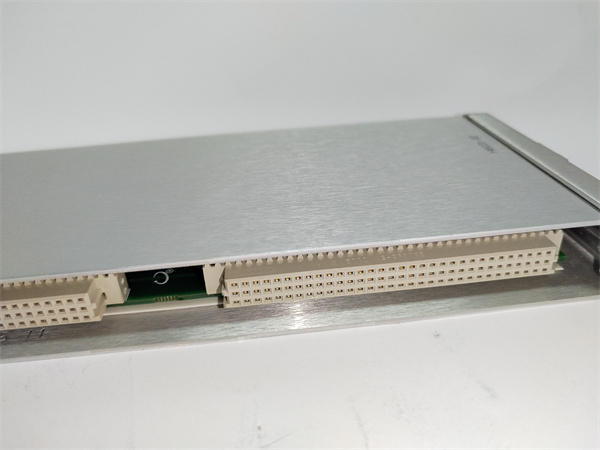

| Product category | High-density signal termination panel for machinery monitoring systems |

| Input channels | 32-channels (fully isolated) |

| Input type | Proximity probes, velocity sensors, accelerometers, temperature sensors |

| Connector type | MIL-C-5015 (field side); terminal block (system side) |

| Isolation rating | 2.5kVrms channel-to-channel and channel-to-ground |

| Operating voltage | 24V DC ±10% |

| Operating temperature | -40°C to 70°C (-40°F to 158°F) |

| Physical dimensions | 483mm x 350mm x 100mm (width x height x depth) |

| Mounting method | Panel mount with DIN rail compatibility |

| Weight | 5.2 kg (11.5 lbs) |

| Compliance | CE, RoHS, ATEX Zone 2, IECEx |

| Compatibility | 3300 series sensors, 3500 monitoring systems, 1900/65A controllers |

BENTLY 146031-02

Product introduction

The 146031-02 from Bently Nevada is a high-density 32-channel signal termination panel, engineered to serve as a centralized connectivity hub for large-scale machinery monitoring systems in industrial environments. As an expanded version of the popular 146031-01, this termination panel builds on its predecessor’s reliability while doubling the channel capacity, making it ideal for complex monitoring applications with numerous sensor points.

Designed to streamline sensor integration in large facilities, the 146031-02 consolidates connections from a wide range of sensors—including proximity probes like the 330130-040-01-00, accelerometers, and temperature devices—into a single, organized panel. Its isolated channels prevent signal interference and ground loops, ensuring measurement integrity even in electrically noisy industrial settings. When paired with high-performance cables such as the 00E04600EFD8 and monitoring controllers like the 1900/65A-01-01-01-00-00, it forms a robust infrastructure for comprehensive machinery health monitoring in power generation, petrochemical, and manufacturing facilities.

Core advantages and technical highlights

Expanded channel capacity: The 146031-02 features 32 fully isolated channels—double the capacity of the 146031-01—enabling centralized termination for large machinery trains or multiple equipment assets. This high-density design reduces the number of panels required for complex monitoring systems, saving valuable rack space in control rooms while simplifying wiring infrastructure and system management.

Enhanced signal isolation: Maintaining the same industry-leading 2.5kVrms isolation between channels and from channels to ground as its predecessor, the 146031-02 provides superior protection against electrical noise, transient voltages, and ground loops. This isolation ensures measurement accuracy even in environments with multiple connected systems and high electromagnetic interference (EMI), such as near large motors, generators, or variable frequency drives.

Modular organization: The panel features a modular channel layout with clear labeling and grouped connectors, simplifying installation, identification, and maintenance. Each set of 16 channels includes dedicated power distribution and status indicators, allowing for systematic troubleshooting and reducing downtime during maintenance activities. This organized structure minimizes wiring errors and eases system expansion.

Industrial-grade durability: Constructed with rugged materials and robust MIL-C-5015 connectors, the 146031-02 withstands harsh industrial environments, including temperature extremes, humidity, and vibration. The field-side connectors provide secure, moisture-resistant connections for sensor cables, while the panel’s sturdy housing protects internal components from dust and physical damage. The design supports extended operation in demanding conditions without performance degradation.

Scalable system integration: The termination panel is fully compatible with Bently Nevada’s 3300 series sensors, 3500 monitoring systems, and 1900/65A controllers, ensuring seamless integration into existing and new monitoring architectures. Its terminal block system-side connections simplify integration with various monitoring equipment, providing flexibility for system expansions or upgrades as facility needs evolve.

Typical application scenarios

In combined cycle power plants, the 146031-02 serves as the central termination point for monitoring an entire gas turbine train, including the turbine, generator, lube oil system, and auxiliary equipment. It consolidates signals from dozens of 330130-040-01-00 proximity probes, accelerometers, and temperature sensors, providing isolated connections to the plant’s 3500 monitoring system. This centralized approach simplifies maintenance during outages and ensures reliable signal transmission in the electrically complex power generation environment.

Within large petrochemical refineries, the 146031-02 is installed in hazardous area control rooms, terminating signals from sensors monitoring multiple compressor trains, pump stations, and heat exchangers. Its ATEX Zone 2 certification ensures safe operation in potentially explosive environments, while the high channel count allows comprehensive monitoring of interconnected process equipment. The panel’s organized layout facilitates quick sensor swapping during maintenance without disrupting entire monitoring loops.

In manufacturing facilities with extensive production lines, the 146031-02 provides centralized sensor termination for multiple production lines, including motors, gearboxes, conveyors, and processing equipment. It connects to a variety of sensors throughout the facility, consolidating their signals for transmission to plant-wide monitoring systems and DCS. This approach simplifies the integration of machinery health data into production management systems, enabling coordinated maintenance scheduling and maximizing overall equipment effectiveness (OEE).

BENTLY 146031-02

Related model recommendations

146031-01: The 16-channel variant of the 146031-02 for smaller monitoring applications.

330130-040-01-00: A proximity probe commonly connected through the 146031-02 panel.

00E04600EFD8: A high-temperature sensor cable ideal for connecting sensors to the panel.

125720-01: A signal conditioning module that integrates with the termination panel.

3500/15: A redundant power supply module for the 146031-02 in critical applications.

1900/65A-01-01-01-00-00: A machinery protection controller compatible with the panel.

1X35668: Cable management hardware for organizing connections to the 146031-02.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 146031-02, ensure the mounting location is in a clean, dry enclosure with adequate ventilation and sufficient space for wiring (minimum 300mm clearance). Verify the panel has appropriate support for its weight. Plan sensor cable routing to the panel, using shielded cables like the 00E04600EFD8 to minimize EMI. For hazardous area installations, confirm the location classification matches the panel’s ATEX Zone 2 rating.

Mounting procedure: Secure the 146031-02 to the panel or DIN rail using appropriate fasteners, ensuring a stable mounting that minimizes vibration transfer. Connect the 24V DC power supply, observing correct polarity and ensuring the supply is properly regulated and fused. Route sensor cables to the field-side MIL-C-5015 connectors, securing each connection with proper torque (1.5 Nm). Connect system-side wiring to the terminal blocks, following the provided wiring diagram for correct signal routing and maintaining proper wire management.

Maintenance suggestions: Inspect the 146031-02 quarterly for loose connections, dust accumulation, or signs of overheating. Clean dust from ventilation slots using compressed air to maintain thermal performance. Verify proper isolation between channels using a megohmmeter during annual maintenance. Check all connectors for corrosion, particularly in humid environments, and clean with a dry cloth if necessary. Label unused channels to prevent accidental connection and maintain detailed documentation of all wiring changes and channel assignments.

Service and guarantee commitment

The 146031-02 is backed by a 3-year warranty covering defects in materials and workmanship under normal operating conditions. Bently Nevada’s global technical support team provides expert assistance for panel configuration, wiring, and troubleshooting, with 24/7 availability for critical system issues.

We offer detailed wiring diagrams and installation guides specific to the 146031-02, ensuring proper integration with sensors and monitoring systems. Training programs cover termination best practices, isolation verification, and maintenance procedures to maximize system reliability. For large-scale installations, we provide on-site commissioning support to ensure proper system integration and optimal performance. Backed by Bently Nevada’s expertise in industrial monitoring infrastructure, the 146031-02 delivers robust signal termination performance you can trust for your most complex machinery protection systems.