Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 1900/55 |

| Manufacturer | Bently Nevada |

| Product category | HMI Interface Panel |

| Series affiliation | 1900 Machinery Protection System |

| Compatible controllers | 1900/27 machinery protection controller |

| Display type | 4-line backlit LCD display |

| User interface | 16-button keypad with tactile feedback |

| Status indicators | 8 LED indicators for system and alarm status |

| Communication interface | RS-485 (Modbus RTU) for connection to 1900/27 |

| Operating voltage | 18-30 VDC (powered via controller or external supply) |

| Power consumption | Max 3W |

| Operating temperature | -20°C to +65°C (-4°F to +149°F) |

| Enclosure rating | NEMA 4X (IP66) when panel-mounted |

| Mounting type | 19-inch rack mount or panel mount |

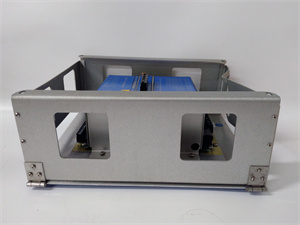

BENTLY 1900/55

Product introduction

The 1900/55 from Bently Nevada is a dedicated HMI interface panel designed specifically for seamless integration with the 1900/27 machinery protection controller. This compact interface serves as the primary local control and visualization hub for the 1900 series protection system, providing operators with real-time access to machinery health data, alarm status, and system configuration. Bently Nevada’s 1900/55 bridges the gap between complex protection system data and operational decision-making, offering intuitive interaction with the 1900/27 controller in industrial environments.

Bently Nevada’s 1900/55 enhances the functionality of the 1900/27 by providing a user-friendly interface for system monitoring and control. Its backlit display presents critical information in a clear, organized format, while the tactile keypad allows for easy navigation through menus, alarm acknowledgment, and configuration adjustments. The 1900/55 ensures that operators can quickly assess machinery status, respond to alarms, and perform essential system functions without requiring specialized technical knowledge, making it an indispensable companion to the 1900/27 in industrial monitoring applications.

Core advantages and technical highlights

Intuitive operation: The 1900/55 features a 4-line backlit LCD display that clearly presents critical information from the 1900/27 controller, including real-time measurements, alarm status, and system diagnostics. Its 16-button keypad with dedicated function keys simplifies navigation through menus, allowing operators to quickly access specific machinery parameters or system functions. This intuitive design reduces training requirements and enables faster response to alarm conditions.

Seamless integration: Specifically engineered for the 1900 series, the 1900/55 establishes reliable communication with the 1900/27 controller via RS-485 Modbus RTU protocol. This native integration ensures accurate data transmission and synchronized operation between the interface panel and protection controller, eliminating compatibility issues common with third-party HMI solutions. The interface automatically recognizes connected sensors and configured parameters from the 1900/27, simplifying system setup.

Industrial durability: Matching the rugged performance of the 1900/27, the 1900/55 features a NEMA 4X (IP66) rated enclosure when panel-mounted, making it suitable for harsh industrial environments. Its wide operating temperature range (-20°C to +65°C) ensures reliable operation in extreme conditions, from freezing outdoor installations to hot factory floors, while its vibration-resistant design maintains functionality in dynamic machinery environments.

Enhanced status visualization: The 1900/55 incorporates 8 dedicated LED indicators that provide at-a-glance status of system health and alarm conditions. These visual indicators complement the detailed display information, allowing operators to quickly assess system status from a distance. The combination of visual alerts and detailed textual information ensures that critical issues are never missed, improving overall system responsiveness.

Typical application scenarios

In oil and gas production facilities, the 1900/55 serves as the local operator interface for 1900/27-protected equipment such as pumps, compressors, and turbines. Mounted near machinery or in local control rooms, it allows on-site personnel to monitor vibration levels, bearing temperatures, and operational status without accessing centralized control systems. When alarms occur, operators can acknowledge alerts, view detailed fault information, and initiate diagnostic checks directly through the 1900/55, facilitating faster troubleshooting and resolution.

Power generation plants utilize the 1900/55 alongside the 1900/27 to provide local monitoring of auxiliary equipment including boiler feed pumps, cooling tower fans, and induced draft fans. The interface panel enables maintenance technicians to check machinery health parameters during rounds, adjust alarm thresholds when necessary, and review historical alarm data to identify emerging issues. Its rugged design withstands the dusty, high-temperature environments common in power plant operations.

Manufacturing facilities deploy the 1900/55 in production areas where the 1900/27 protects critical rotating equipment on assembly lines and processing stations. The interface panel allows line operators to monitor equipment condition during production runs, ensuring that machinery operates within safe parameters. In the event of abnormal conditions, the 1900/55 provides clear guidance on required actions, helping operators make informed decisions that balance production continuity with equipment protection.

BENTLY 1900/55

Related model recommendations

1900/27 (Bently Nevada): Machinery protection controller that forms the core system with the 1900/55 interface panel.

1900/16 (Bently Nevada): Expansion module whose data is visualized and controlled through the 1900/55.

60M100-00 (Bently Nevada): Advanced display unit that can complement the 1900/55 for centralized monitoring.

330180-90-01 (Bently Nevada): Proximity sensor whose measurements are displayed on the 1900/55.

133819-01 (Bently Nevada): Signal conditioner whose processed data appears on the 1900/55 interface.

24765-02-00 (Bently Nevada): Case expansion transducer whose data is accessible through the 1900/55.

125840-01 (Bently Nevada): Power supply module that can provide power to both the 1900/55 and 1900/27.

3500/92 (Bently Nevada): Communication gateway that can extend data from the 1900/27 and 1900/55 to plant networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 1900/55, ensure the mounting location provides clear visibility for operators and is protected from direct physical impact. Verify compatibility with the connected 1900/27 controller and confirm communication cabling meets RS-485 specifications (twisted pair, shielded). Required tools include mounting hardware, torque screwdrivers, and a multimeter for power verification. Inspect the 1900/55 for shipping damage, particularly checking the display screen and keypad functionality. Plan cable routes to minimize electromagnetic interference from nearby power cables.

Maintenance suggestions: Conduct quarterly inspections of the 1900/55 to ensure the display remains legible and all keypad buttons function properly. Clean the front panel with a soft, dry cloth; avoid chemical cleaners that may damage the display or keypad. Verify LED indicators illuminate correctly during system startup. Check communication connections periodically to ensure secure, corrosion-free connections with the 1900/27. Backup system configurations through the interface or connected controller. If display issues occur, first check power supply integrity before troubleshooting communication with the 1900/27 controller.

Service and guarantee commitment

Bently Nevada provides the 1900/55 with a 24-month warranty covering manufacturing defects and component failures from the date of shipment. Our technical support team offers expert assistance for integration with the 1900/27 controller, configuration, and troubleshooting of the 1900/55 interface panel.

We offer specialized training on effectively utilizing the 1900/55 with the 1900/27 system, ensuring your operators can maximize system functionality. Beyond the warranty period, our service agreements include preventive maintenance checks and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures the 1900/55 delivers reliable interface functionality throughout its operational lifecycle, backed by our global network of service professionals and application engineers.