Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 1X35668 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Sensor mounting hardware kit for proximity probes |

| Compatible sensors | 3300 series proximity probes (e.g., 330130-080-00-CN) |

| Material composition | Stainless steel (316 grade) components, nickel-plated brass adapters |

| Kit contents | Mounting bracket, locknut, spacer, washer, cable gland, and installation tools |

| Bracket dimensions | 65mm x 45mm x 10mm (length x width x thickness) |

| Adjustment range | ±5mm vertical/horizontal positioning adjustment |

| Temperature rating | -54°C to 204°C (-65°F to 400°F) |

| Corrosion resistance | IP68 rated for harsh environments |

| Weight | 0.25 kg (0.55 lbs) |

| Compliance | RoHS, CE, ATEX Zone 2 compliant |

| Application suitability | Indoor/outdoor, hazardous and non-hazardous areas |

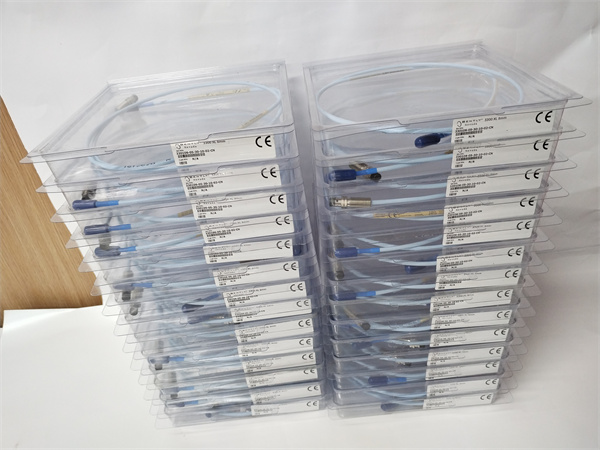

BENTLEY 330130-080-00-CN

Product introduction

The 1X35668 from Bently Nevada is a precision-engineered sensor mounting hardware kit, specifically designed to secure proximity probes in industrial machinery monitoring systems. As a critical accessory in Bently Nevada’s 3300 series ecosystem, the 1X35668 provides a robust, adjustable mounting solution that ensures optimal sensor positioning for accurate vibration and shaft position measurements.

Crafted from high-grade materials, this mounting kit addresses the unique challenges of installing proximity probes in harsh industrial environments. It ensures proper alignment between sensors and rotating machinery components—such as turbine shafts, motor rotors, and compressor journals—while protecting delicate sensor cables from mechanical stress and environmental damage. Whether deployed in power generation, oil and gas, or chemical processing facilities, the 1X35668 enhances measurement reliability by maintaining consistent sensor positioning even under extreme operating conditions.

Core advantages and technical highlights

Industrial-grade durability: The 1X35668 features 316 stainless steel components and nickel-plated brass adapters, providing exceptional resistance to corrosion, high temperatures, and chemical exposure. This material selection makes it ideal for installations in coastal, offshore, or chemical processing environments where standard hardware would degrade quickly. The kit’s robust construction ensures long-term stability, preventing sensor drift that could compromise measurement accuracy.

Precision adjustment capabilities: Unlike fixed mounting solutions, the 1X35668 offers ±5mm of vertical and horizontal adjustment, allowing technicians to fine-tune probe positioning during installation. This adjustability is critical for achieving the optimal 0.5mm-1.0mm gap required for proximity probe operation, ensuring accurate measurement of shaft vibration and displacement. The kit’s incremental adjustment mechanism enables precise calibration without damaging sensitive sensor tips.

Integrated cable protection: The 1X35668 includes a specialized cable gland and strain relief system that secures probe cables while preventing moisture ingress and mechanical stress. This feature protects vulnerable cable connections from vibration-induced fatigue and environmental contaminants, extending sensor service life and reducing maintenance requirements. The cable management design also minimizes electromagnetic interference (EMI) by maintaining proper cable routing away from noise sources.

Typical application scenarios

In gas turbine power plants, the 1X35668 is used to mount proximity probes on turbine casings for shaft vibration monitoring. Its high-temperature tolerance (up to 204°C) withstands the thermal conditions near turbine exhaust sections, while the corrosion-resistant materials resist degradation from turbine oils and combustion byproducts. The adjustable mounting allows precise alignment with turbine shafts, ensuring accurate measurement of rotor imbalance and misalignment.

Within offshore oil platforms, the 1X35668 secures proximity probes on subsea pump motors and compressor shafts. Its 316 stainless steel construction resists saltwater corrosion and humidity, while the IP68 rating prevents water ingress during platform washdowns or flooding events. The kit’s ATEX compliance makes it suitable for hazardous areas where flammable gases may be present.

In chemical processing facilities, the 1X35668 provides reliable mounting for proximity probes monitoring agitator shafts and mixer rotors. Its chemical-resistant materials withstand exposure to process fluids and cleaning agents, while the secure locking mechanism prevents sensor movement during equipment operation. The adjustable bracket accommodates thermal expansion/contraction of machinery, maintaining optimal probe-to-shaft clearance despite temperature fluctuations.

BENTLEY 330106-05-30-10-02-CN

Related model recommendations

1X35669: A heavy-duty variant of the 1X35668 with extended bracket length for larger machinery installations.

1X35670: A low-profile version of the 1X35668 designed for space-constrained applications.

330130-080-00-CN: A proximity probe commonly paired with the 1X35668 mounting kit.

129478-01: A sensor cable that integrates with the 1X35668’s cable gland system.

330180-91-CN: A calibration tool used with systems installed using the 1X35668 kit.

133292-01: A junction box compatible with sensor installations using the 1X35668 hardware.

125760-01: A signal conditioner that processes data from probes mounted with the 1X35668 kit.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 1X35668, verify that the mounting surface is clean, flat, and capable of supporting the hardware and sensor weight. Ensure the installation area allows for the recommended sensor-to-target clearance (typically 0.5mm-1.0mm). Prepare the mounting location by removing debris, rust, or paint that could affect bracket stability. Gather required tools (included in the kit) and ensure work area is properly isolated from machinery operation.

Mounting procedure: Secure the base bracket to the machinery frame using appropriate fasteners (not included, selected based on surface material). Attach the proximity probe to the adjustable mounting block using the provided locknut, leaving sufficient thread for position adjustment. Connect the sensor cable to the probe and route through the cable gland, tightening the gland to create a waterproof seal. Position the probe to achieve the target gap using the adjustment screws, then lock the position using the locking hardware. Verify alignment using a dial indicator before final tightening.

Maintenance suggestions: Inspect the 1X35668 mounting hardware quarterly for signs of loosening, corrosion, or damage. Retighten any hardware showing movement using the provided tools, being careful not to disturb sensor alignment. Clean stainless steel components with a mild detergent to remove accumulated debris or chemical residues. Check cable gland integrity during each inspection to ensure moisture sealing remains effective. In high-vibration environments, perform monthly inspections to maintain proper sensor positioning.

Service and guarantee commitment

The 1X35668 is backed by a 3-year warranty covering defects in materials and workmanship under normal operating conditions. Bently Nevada’s global technical support team provides expert guidance on installation techniques, alignment procedures, and maintenance best practices, with 24/7 availability for critical system inquiries.

We offer detailed installation guides and alignment templates specific to the 1X35668, ensuring proper integration with 3300 series proximity probes. Training modules cover optimal mounting techniques for various machinery types, helping technicians achieve accurate sensor positioning. For customers requiring custom mounting solutions, our engineering team can modify the 1X35668 design to meet unique application requirements. Backed by Bently Nevada’s expertise in industrial sensor systems, the 1X35668 delivers reliable mounting performance you can trust in critical machinery monitoring applications.