Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 22810-01-05-50-02 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Vibration transmitter with built-in sensor |

| Measurement principle | Piezoelectric accelerometer with integrated signal conditioning |

| Measurement range | 0-50mm/s peak velocity (configurable); 0-5g acceleration |

| Frequency response | 1Hz to 10kHz |

| Output signal | 4-20mA analog output (proportional to vibration velocity) |

| Operating voltage | 18-30V DC |

| Operating temperature | -40°C to 85°C (-40°F to 185°F) |

| Physical dimensions | 38mm diameter x 55mm length (1.5in x 2.2in) |

| Mounting method | 10-32 UNF stud mount; magnetic base option available |

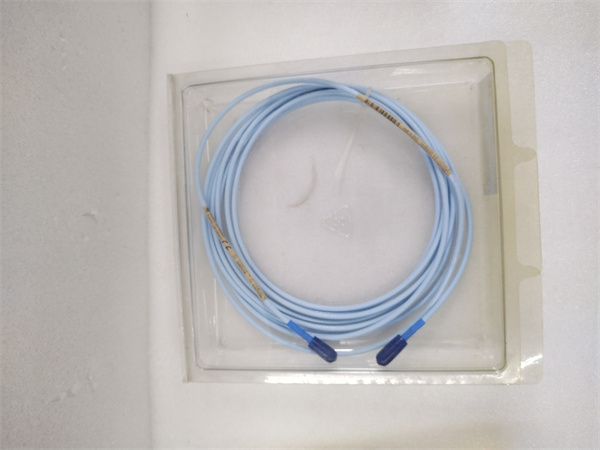

| Cable length | 5m (16.4ft) integral shielded cable |

| Connector type | M12 circular connector with IP67 rating |

| Material construction | 316 stainless steel housing, hermetically sealed |

| Weight | 220g (7.8oz) |

| Compliance | CE, RoHS, ATEX Zone 2, IECEx, ISO 10816-3 |

BENTLY 330130-045-00-00

Product introduction

The 22810-01-05-50-02 from Bently Nevada is an all-in-one vibration transmitter, combining a piezoelectric accelerometer with integrated signal conditioning in a compact, rugged package. As a key component in Bently Nevada’s machinery health monitoring portfolio, this device simplifies vibration monitoring by delivering industry-standard 4-20mA output directly from the sensor, eliminating the need for separate signal conditioners in basic to mid-range monitoring applications.

Designed for ease of integration into industrial control systems, the 22810-01-05-50-02 measures vibration velocity (0-50mm/s peak) and acceleration (0-5g) from machine surfaces, making it suitable for monitoring motors, pumps, fans, and other rotating equipment. Its 5m integral cable and M12 connector ensure straightforward installation, while the stainless steel construction ensures reliable operation in harsh industrial environments. Whether deployed in manufacturing plants, power facilities, or processing industries, this transmitter provides critical vibration data for predictive maintenance and condition monitoring programs.

Core advantages and technical highlights

Integrated design simplicity: The 22810-01-05-50-02 combines sensor and signal conditioning in one device, reducing installation complexity and eliminating potential signal loss points between separate components. This all-in-one design simplifies system architecture, lowers inventory requirements, and reduces wiring costs compared to traditional sensor+conditioner setups. The integrated electronics convert raw vibration data directly to a 4-20mA signal proportional to vibration velocity, easily interpreted by PLCs, DCS, and SCADA systems.

Industrial-grade reliability: Encased in a hermetically sealed 316 stainless steel housing, the 22810-01-05-50-02 withstands extreme temperatures (-40°C to 85°C), moisture, dust, and chemical exposure. Its IP67-rated M12 connector ensures secure, waterproof connections, while the rugged cable design resists abrasion and mechanical stress. The transmitter’s robust construction survives shocks up to 500g and vibrations up to 20g, ensuring reliable operation in high-vibration environments like industrial mills and offshore platforms.

Flexible configuration: The 22810-01-05-50-02 offers configurable measurement ranges and output scaling to match specific machinery requirements, with factory or field calibration options available. Its broad frequency response (1Hz to 10kHz) captures both low-frequency structural vibrations and high-frequency bearing defects, providing comprehensive machinery health data. The transmitter supports direct connection to standard industrial control systems without specialized interface modules.

Hassle-free installation: With its integral 5m cable, M12 connector, and versatile mounting options (10-32 stud or optional magnetic base), the 22810-01-05-50-02 simplifies installation in space-constrained locations. The plug-and-play design reduces setup time, while the shielded cable minimizes electromagnetic interference (EMI) from nearby motors and drives.

BENTLY 330130-040-00-00

Typical application scenarios

In water and wastewater treatment plants, the 22810-01-05-50-02 monitors pump and blower vibration, providing critical data to prevent unplanned downtime. Mounted directly on pump bearing housings, it detects early signs of impeller imbalance, bearing wear, and cavitation through vibration velocity measurements. The transmitter’s corrosion-resistant stainless steel housing withstands the humid, chemically exposed environment, while the 4-20mA output integrates seamlessly with the plant’s SCADA system for centralized monitoring.

Within food and beverage processing facilities, the 22810-01-05-50-02 monitors mixing equipment, conveyors, and bottling machinery. Its hermetic sealing and washdown-resistant design survive frequent cleaning cycles, while the vibration data helps maintain production quality by detecting equipment issues that could affect product consistency. The transmitter’s ATEX certification allows safe operation in areas with potentially explosive dust atmospheres.

In manufacturing facilities, the 22810-01-05-50-02 provides widespread vibration monitoring across production lines, with multiple transmitters connected to a central PLC. This cost-effective solution enables condition monitoring of motors, gearboxes, and compressors, identifying maintenance needs before equipment failures disrupt production schedules. The transmitter’s simple integration reduces the barrier to implementing predictive maintenance programs.

Related model recommendations

22810-01-05-25-02: A lower-range variant of the 22810-01-05-50-02 with 0-25mm/s velocity range for less dynamic machinery.

22810-01-05-50-03: A high-temperature version with extended -40°C to 125°C operating range for extreme heat applications.

1X35668: A mounting adapter kit for secure installation of the 22810-01-05-50-02 in challenging locations.

129478-01: A compatible extension cable for installations requiring longer than 5m cable length.

330180-91-CN: A calibration tool for verifying the performance of the 22810-01-05-50-02 transmitter.

133292-01: A junction box for centralized connection of multiple 22810-01-05-50-02 transmitters.

3500/22-01-00: A display module that visualizes vibration data from the 22810-01-05-50-02 in control rooms.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 22810-01-05-50-02, select a mounting location on the machine casing near bearing housings for optimal vibration transfer. Ensure the surface is clean, flat, and free of paint or corrosion. For hazardous area installations, verify the location classification matches the transmitter’s ATEX Zone 2 rating. Plan cable routing to avoid sharp edges, moving parts, and EMI sources, maintaining the minimum bend radius of 25mm.

Mounting procedure: Secure the 22810-01-05-50-02 using the 10-32 UNF stud, torquing to 3.5 Nm (31 in-lbs) for proper vibration transfer. For temporary installations, use the optional magnetic base accessory. Connect the M12 connector to the field wiring, ensuring the connector is fully seated and the locking ring is tightened to achieve IP67 sealing. Connect the 18-30V DC power supply and verify the 4-20mA output corresponds to ambient vibration levels.

Maintenance suggestions: Inspect the 22810-01-05-50-02 quarterly for signs of physical damage, loose mounting, or cable wear. Verify the mounting torque remains at specification, as loose mounting can cause measurement errors. Check the M12 connector for corrosion or damage, particularly in humid environments. Clean the housing with a mild detergent if contaminated, avoiding abrasive materials. Perform calibration verification annually using a vibration calibrator to ensure measurement accuracy.

Service and guarantee commitment

The 22810-01-05-50-02 is backed by a 2-year warranty covering defects in materials and workmanship under normal operating conditions. Bently Nevada’s global technical support team provides expert assistance for installation, configuration, and troubleshooting, with 24/7 availability for critical system issues.

We offer factory calibration services for the 22810-01-05-50-02, ensuring compliance with ISO 10816-3 standards for machinery vibration. Technical documentation includes wiring diagrams, mounting guidelines, and application notes to maximize performance. Training programs cover vibration monitoring principles and transmitter integration, helping users effectively interpret data from the 22810-01-05-50-02. Backed by Bently Nevada’s expertise in industrial condition monitoring, this transmitter delivers reliable performance for protecting your machinery assets.