Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 330130-045-00-00 |

| Manufacturer | Bently Nevada (a division of GE Vernova) |

| Product category | Proximity probe for machinery vibration and position monitoring |

| Measurement principle | Eddy current technology |

| Target material | Ferromagnetic metals (steel, iron alloys) |

| Measurement range | 0 to 4.5mm (0 to 0.177in) linear displacement |

| Frequency response | 0Hz to 10kHz |

| Output signal | -2V to -10V DC (proportional to gap) |

| Operating temperature | -54°C to 204°C (-65°F to 400°F) |

| Probe length | 152mm (6.0in) |

| Probe diameter | 11mm (0.43in) |

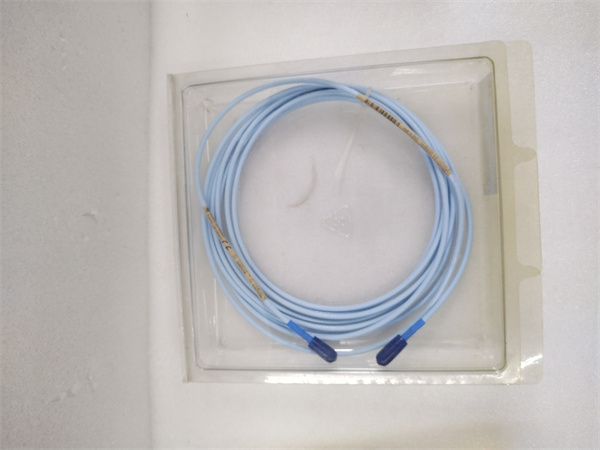

| Cable length | 7.6m (25ft) standard (integral shielded cable) |

| Connector type | MIL-C-5015 compatible with enhanced sealing |

| Material construction | Inconel 718 probe tip, 316 stainless steel housing |

| Weight | 0.42 kg (0.93 lbs) |

| Compliance | CE, RoHS, ATEX Zone 1/2 compliant, IECEx |

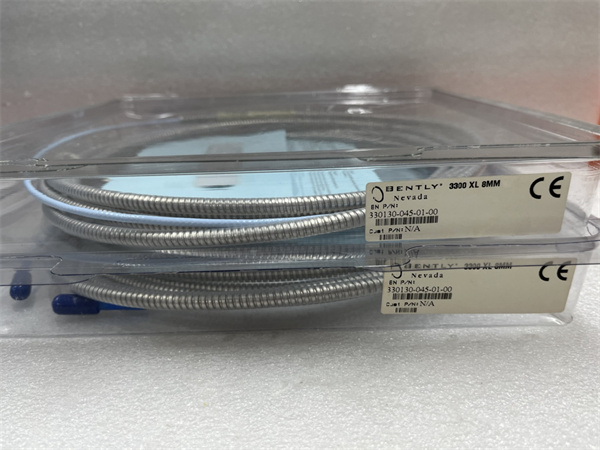

BENTLY 330130-045-00-00

Product introduction

The 330130-045-00-00 from Bently Nevada is a high-performance proximity probe, representing an enhanced variant in the 3300 series machinery protection system—renowned as the industry benchmark for monitoring critical rotating equipment. Leveraging advanced eddy current technology, this proximity probe delivers precise non-contact measurement of shaft displacement, vibration, and position in the most demanding industrial environments.

As an upgraded version of the 330130-040-00-00, the 330130-045-00-00 offers an extended measurement range and enhanced temperature tolerance, making it ideal for applications requiring greater displacement monitoring capability and operation in higher-temperature environments. When paired with compatible signal conditioners like the 125760-01 and mounting hardware such as the 1X35668 kit, this probe forms a robust foundation for predictive maintenance programs, enabling early detection of machinery issues before they escalate into costly failures.

Core advantages and technical highlights

Extended measurement capability: The 330130-045-00-00 provides an expanded 4.5mm measurement range (0.5mm more than the 330130-040-00-00), making it suitable for machinery with greater expected shaft movement, such as large industrial pumps, turbines, and compressors. This extended range maintains exceptional linearity with typical error below ±1% of full scale, ensuring accurate measurement of both subtle vibrations and larger displacement events.

Enhanced temperature resilience: With an operating temperature range extended to 204°C (35°F higher than the 330130-040-00-00), the 330130-045-00-00 excels in high-heat environments like gas turbine enclosures, steam turbine auxiliaries, and high-temperature process pumps. Its Inconel 718 probe tip and 316 stainless steel housing resist thermal degradation, maintaining measurement accuracy even under prolonged exposure to extreme temperatures.

Superior environmental protection: The 330130-045-00-00 features enhanced sealing and ruggedized construction that exceeds the protection level of the standard model. Its advanced connector design with improved sealing provides superior resistance to moisture, dust, and chemical ingress, while the extended 7.6m shielded cable offers greater flexibility in routing away from heat sources and electrical noise in large machinery installations.

Hazardous area certification: Unlike the standard model, the 330130-045-00-00 carries ATEX Zone 1/2 and IECEx certifications, making it suitable for installation in potentially explosive environments such as refineries, chemical plants, and offshore oil platforms where flammable gases or dust may be present.

Typical application scenarios

In gas turbine power plants, the 330130-045-00-00 is installed in turbine enclosures to monitor shaft vibration and position near the combustion section. Its extended temperature tolerance withstands the high heat environment, while the expanded measurement range accommodates the greater shaft movement typical in these large rotating machines. The probe’s data helps operators detect early signs of rotor imbalance or bearing degradation in critical turbine components.

Within petroleum refineries, the 330130-045-00-00 monitors pump and compressor shafts in hazardous processing areas. Its ATEX certification ensures safe operation in potentially explosive environments, while the enhanced chemical resistance of its 316 stainless steel housing withstands exposure to hydrocarbons and cleaning agents. The extended cable length allows routing to remote junction boxes outside hazardous zones.

In large chemical processing facilities, the 330130-045-00-00 is deployed on high-temperature agitators and reactor mixers. Its ability to operate at 204°C makes it ideal for monitoring equipment near heated vessels, while the expanded measurement range accommodates the larger shaft movements common in these machines. The probe’s reliable performance helps prevent unplanned downtime in continuous production processes.

BENTLY 330130-045-00-00

Related model recommendations

330130-040-00-00: The standard-range counterpart with 4.0mm measurement capability for applications with moderate shaft movement requirements.

330130-085-00-CN: A larger-range variant with 8.5mm measurement capability for machinery with significant displacement potential.

1X35668: A precision mounting hardware kit optimized for secure installation of the 330130-045-00-00 in high-vibration environments.

125760-01: A signal conditioner that processes the probe’s output for integration with control systems and data acquisition platforms.

129478-01: A compatible extension cable for installations requiring lengths beyond the probe’s integral 7.6m cable.

330180-91-CN: A calibration tool specifically designed to verify the performance of the 330130-045-00-00 probe.

133292-01: A hazardous-area-rated junction box that provides secure termination for the probe in explosive environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 330130-045-00-00, verify the mounting surface can support the probe and 1X35668 hardware in high-temperature conditions. Ensure the target shaft material is ferromagnetic and clean of debris that could affect measurements. For hazardous area installations, confirm the location classification matches the probe’s ATEX Zone 1/2 rating. Plan cable routing to maintain the minimum bend radius (15mm static, 30mm dynamic) and avoid contact with surfaces exceeding 204°C.

Mounting procedure: Secure the 1X35668 bracket to a rigid, thermally stable surface using high-temperature fasteners. Attach the 330130-045-00-00 probe and adjust to achieve the recommended 0.75mm-1.5mm initial gap—slightly wider than the standard model to accommodate its extended range. Use a precision multimeter to verify the -2V to -10V output corresponds correctly to the gap setting. In hazardous areas, ensure all connections comply with local explosion protection regulations and use certified cable glands.

Maintenance suggestions: Inspect the 330130-045-00-00 quarterly, with special attention to the probe tip condition and cable insulation integrity in high-heat areas. Clean the Inconel tip with a non-abrasive cloth if contaminated. Verify gap voltage monthly in critical applications, adjusting using the mounting hardware as needed. Check connector seals regularly to ensure environmental protection remains intact. Perform annual calibration with the 330180-91-CN tool, and in hazardous areas, ensure maintenance procedures follow lockout/tagout and explosion protection protocols.

Service and guarantee commitment

The 330130-045-00-00 is backed by a 2-year warranty covering defects in materials and workmanship under normal operating conditions, with extended warranty options available for critical applications. Bently Nevada’s global technical support team provides specialized assistance for high-temperature and hazardous area installations, with 24/7 availability for critical system issues.

We offer specialized training on installation in hazardous environments and high-temperature applications specific to the 330130-045-00-00, including proper gap setting, cable management, and certification compliance. Calibration services include hazardous area verification to maintain certification validity. Backed by Bently Nevada’s expertise in extreme environment monitoring, the 330130-045-00-00 delivers reliable performance you can trust in your most demanding machinery protection applications.