Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/22M |

| Manufacturer | Bently Nevada |

| Product category | Primary Power Supply Module for Machinery Protection Systems |

| Series affiliation | 3500 Machinery Protection System |

| Output voltage | 5 VDC (3 A), ±15 VDC (1 A each) |

| Input voltage range | 100-240 VAC (50/60 Hz) or 18-32 VDC |

| Maximum power rating | 30 W |

| Efficiency | >85% at full load |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Protection mechanisms | Overvoltage, overcurrent, and short circuit protection |

| Redundancy support | N+1 redundant configuration capability |

| Key variants | 3500/22M 138607-01 (standard industrial grade) |

| Compatibility | All 3500 series modules, including 3500/15, 3500/61, 127610-01 |

| Certifications | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Diagnostic features | Power status LEDs, voltage monitoring, fault reporting via system bus |

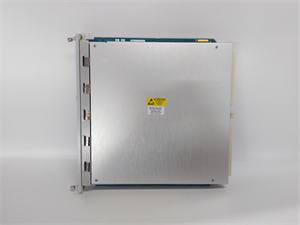

BENTLY 3500/22M

Product introduction

The 3500/22M from Bently Nevada represents the cornerstone power supply solution for 3500 Machinery Protection Systems, delivering the stable and reliable electrical power required for continuous machinery monitoring and protection. As the primary energy source for the entire 3500 ecosystem, this rack-mount power supply converts incoming AC or DC power into precisely regulated DC outputs that energize all critical system components—from sensors and monitoring modules to display interfaces and protective relays like the 127610-01 assembly.

Bently Nevada engineered the 3500/22M to address the unique power requirements of safety-critical machinery protection applications, where even momentary power interruptions could compromise equipment safety. Its robust design ensures consistent operation across varying load conditions and input power fluctuations, making it the ideal power solution for industries ranging from power generation and oil & gas to manufacturing and chemical processing. The 3500/22M 138607-01 variant, as the standard implementation of this platform, embodies these principles with specific hardware optimized for industrial environments.

Core advantages and technical highlights

Precision voltage regulation

At the heart of the 3500/22M is its advanced regulation circuitry that maintains output voltages within tight tolerances (±2% for 5 VDC, ±3% for ±15 VDC) regardless of input variations or load changes. This stability is critical for sensitive electronics in modules like the 3500/61 display and 127610-01 relay assemblies, preventing measurement errors and false alarms that could result from voltage fluctuations.

Dual input capability

The 3500/22M uniquely supports both AC (100-240 VAC) and DC (18-32 VDC) input sources, providing unmatched flexibility in installation. This dual capability allows seamless integration into diverse industrial power systems—from standard AC mains in control rooms to DC power grids in hazardous locations or remote installations, eliminating the need for external power converters.

Comprehensive protection suite

Equipped with multi-layer protection mechanisms, the 3500/22M safeguards both itself and connected components. Overvoltage protection prevents voltage spikes from reaching sensitive electronics, overcurrent protection limits damage during fault conditions, and short circuit protection ensures safe operation even with accidental wiring errors—critical for protecting expensive modules like the 3500/15 relay module.

Redundancy readiness

The 3500/22M is designed for N+1 redundancy, allowing multiple power supplies to operate in parallel. This configuration ensures uninterrupted system operation even if one supply fails, with automatic load sharing between units. Redundancy is particularly valuable in safety-critical applications where protection system downtime could lead to equipment damage or production losses.

Variant specifications: 3500/22M 138607-01

The 3500/22M 138607-01 serves as the standard production variant of the 3500/22M platform, incorporating all core features with hardware optimized for industrial reliability. This variant includes enhanced thermal management for extended operation at maximum load, reinforced connectors for vibration resistance, and factory-calibrated regulation circuits that maintain performance throughout the product lifecycle. It retains full compatibility with all 3500 series components, making it the default choice for new installations and system upgrades.

Typical application scenarios

Power generation

In turbine and generator protection systems, 3500/22M units are installed in redundant pairs to provide uninterrupted power to vibration monitors, temperature transmitters, and safety relays. During mains power fluctuations common in power plants, the stable output ensures protection systems continue monitoring critical parameters and can actuate 127610-01 relays to trigger shutdowns if necessary.

Oil and gas production

In compressor stations and pipeline facilities, the 3500/22M operates from 24 VDC control power systems, delivering reliable power to explosion-proof monitoring equipment. Its robust design withstands the electrical noise and environmental conditions typical in these facilities, ensuring protection systems remain operational even in harsh environments.

Manufacturing

On production lines, 3500/22M power supplies provide clean power to machinery protection systems monitoring motors, pumps, and gearboxes. Their ability to filter electrical noise from factory equipment ensures accurate measurements from sensors and reliable operation of emergency stop relays, enhancing both equipment protection and worker safety.

BENTLY 3500/22M

System integration ecosystem

The 3500/22M forms the power backbone of the 3500 system, supporting key components including:

3500/15 relay modules with 127610-01 assemblies

3500/61 display modules

3500/34 communication gateways

125720-01 temperature transmitters

135137-01 input modules

3500/70M reciprocating machinery monitors

Its standardized rack-mount design fits seamlessly into 3500/20 system racks, creating a unified protection system where all components receive regulated power from a common, reliable source.

Installation and maintenance guidelines

Installation best practices

Mount the 3500/22M in the bottom slots of the 3500/20 rack to facilitate power distribution to upper modules. For redundant configurations, install supplies in separate rack locations and connect to independent input power sources. Use appropriately sized wiring for input connections (18-22 AWG) and ensure proper grounding to minimize noise and enhance safety.

Maintenance procedures

Perform quarterly inspections to verify status LEDs indicate normal operation. Measure output voltages annually using a calibrated multimeter to ensure regulation remains within specifications. In redundant systems, test failover capability semi-annually by temporarily disconnecting one supply. Clean ventilation openings regularly to prevent thermal degradation. Plan replacement of units after 5-7 years of operation to maintain reliability.

Service and warranty

Bently Nevada provides a 36-month warranty for all 3500/22M units, covering manufacturing defects and performance issues. The warranty includes the 3500/22M 138607-01 variant and guarantees voltage regulation accuracy, protection feature functionality, and mechanical integrity under normal operating conditions. Technical support includes assistance with installation, redundancy configuration, and troubleshooting, with global service coverage ensuring prompt response to service needs. Extended service agreements are available to provide preventive maintenance, calibration verification, and expedited replacement services beyond the standard warranty period.