Description

Detailed parameter table

| Parameter name | Parameter value |

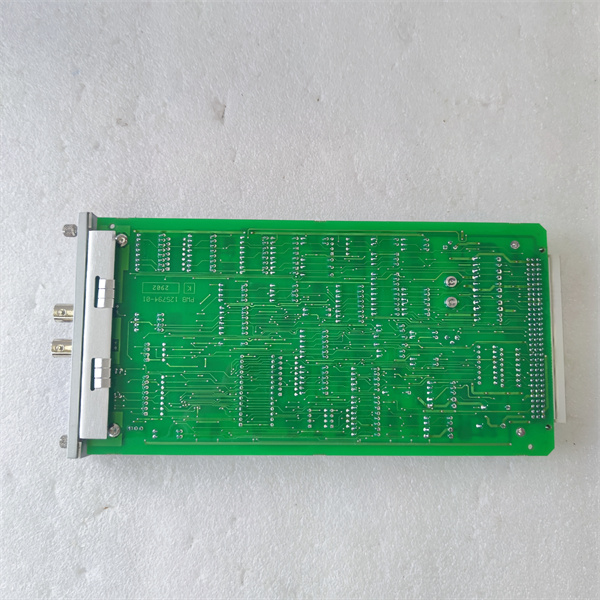

| Product model | 3500/25-01-01-00 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Relay Output Module |

| Relay channels | 8 independent Form C (changeover) relays |

| Relay rating | 5 A @ 250 VAC, 5 A @ 30 VDC |

| Response time | <10 ms |

| Input signals | Digital alarm inputs from 3500 system modules |

| Configuration | Software-configurable logic, latching/non-latching modes |

| Communication interface | 3500 system backplane, integrated with 3500/92 136188-02 |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15-05-05-00 power supply) |

| Power consumption | 6 W typical, 8 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 3500/33-01-00 process monitors, 3500/40M 176449-01 vibration monitors |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved

Product introduction |

BENTLY 3500/25-01-01-00

The 3500/25-01-01-00 from Bently Nevada is a critical relay output module designed to translate alarm signals from the 3500 Machinery Protection System into actionable protective actions, serving as the safety enforcement component in industrial monitoring architectures. This 2-slot rack-mounted module features 8 independent relays that convert digital alarm outputs from monitoring modules into physical control signals, enabling automated responses to machinery health and process condition deviations.

Unlike generic industrial relays, 3500/25-01-01-00 is engineered specifically for seamless integration with the 3500 system ecosystem, ensuring reliable execution of protective logic based on alarms from process monitors like 3500/33-01-00 and vibration monitors such as 3500/40M 176449-01. It works in close coordination with the 3500/92 136188-02 rack interface to implement configurable safety strategies, bridging the gap between monitoring data and equipment protection.

In industrial safety systems, 3500/25-01-01-00 plays an indispensable role in preventing machinery damage and ensuring operational safety by triggering timely protective actions. Its robust relay design and configurable logic make it suitable for medium-complexity protection scenarios across manufacturing, power generation, and medium-duty oil and gas facilities, where reliable alarm response is critical for asset protection and personnel safety.

Core advantages and technical highlights

Flexible relay configuration: 3500/25-01-01-00 features 8 independently configurable Form C (changeover) relays that can be individually programmed to respond to specific alarm conditions from monitoring modules like 3500/33-01-00. Each relay supports both latching and non-latching operation modes, with software-configurable logic that enables complex protection strategies—from simple alarm-to-relay mapping to logic combinations requiring multiple alarm conditions to be met before triggering a response.

Reliable high-current switching: The module’s relays are rated for 5 A at 250 VAC/30 VDC, providing sufficient current handling capability to control contactors, valves, alarms, and shutdown circuits in industrial machinery. This robust switching capacity ensures that protective actions are executed reliably even in demanding applications, while the relays’ mechanical design supports millions of operations for long service life in critical safety roles.

Seamless system integration: 3500/25-01-01-00 communicates directly with the 3500 backplane, receiving real-time alarm status from all connected monitoring modules including 3500/33-01-00 process monitors and vibration sensors. This integration with the 3500/92 136188-02 interface enables centralized configuration of relay logic, status monitoring, and diagnostic reporting, ensuring protection strategies remain aligned with overall system configuration.

Rapid response capability: With a response time of less than 10 ms from alarm detection to relay activation, the module ensures timely execution of protective actions when critical conditions are detected. This rapid response is essential for preventing machinery damage in scenarios where seconds matter, such as detecting high bearing temperatures from 3500/33-01-00 and immediately activating cooling systems or initiating shutdown procedures.

Typical application scenarios

In manufacturing plants, 3500/25-01-01-00 modules provide protective relay functionality for production line machinery, receiving alarm signals from 3500/33-01-00 monitors tracking bearing temperatures and hydraulic pressures. The module’s relays are configured to trigger cooling system activation when temperature thresholds are exceeded and to sound local alarms for pressure deviations. In critical situations, higher-priority relays initiate controlled shutdowns of conveyor systems or mixers, preventing equipment damage while minimizing production disruption.

Power generation facilities utilize 3500/25-01-01-00 in auxiliary equipment protection systems, where relays respond to vibration alarms from 3500/40M 176449-01 and temperature alarms from 3500/33-01-00. The module implements tiered protection strategies: first activating alarm indicators for minor deviations, then initiating lubrication system adjustments for moderate conditions, and finally triggering emergency shutdowns for critical situations like excessive bearing temperatures combined with abnormal vibration patterns.

Medium-duty oil and gas facilities employ 3500/25-01-01-00 to protect pump stations and compression equipment, with relays controlling isolation valves, pressure relief systems, and emergency shutdown circuits. The module responds to process alarms from 3500/33-01-00 such as high discharge pressure or low suction pressure, activating appropriate protective measures while sending status signals to the central control system via the 3500/92 136188-02 interface. This ensures coordinated protection across interconnected equipment systems.

BENTLY 3500/25-01-01-00

Related model recommendations

3500/33-01-00: Process monitor whose alarm signals trigger this relay module.

3500/92 136188-02: Rack interface module configuring and monitoring this relay unit.

3500/15-05-05-00: Power supply module providing reliable power to this relay module.

3500/40M 176449-01: Vibration monitor whose alarms activate protective relays.

3500/60 163179-01: Display module showing relay activation status and alarms.

3500/05-01-02-00-00-01: Communication module transmitting relay status to SCADA.

177230-01-01-05: Extension cable supporting sensor connections in protected systems.

3500/25-02-01-00: Advanced relay module with enhanced diagnostic capabilities.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/25-01-01-00, verify the 3500 rack has two adjacent slots available and that a 3500/15-05-05-00 power supply is properly installed. Ensure the module is positioned in the rack to allow easy access to relay terminals for field wiring connections. Use appropriately rated wiring (18-14 AWG) for relay outputs based on connected loads, with separate conduit for power and signal wiring to minimize interference. Configure relay logic parameters via the 3500/92 136188-02 interface before final connection of controlled devices.

Maintenance suggestions: Include 3500/25-01-01-00 in quarterly safety system inspections, verifying all 8 relays operate correctly by testing both manual activation and alarm-triggered operation. Check relay contacts for signs of arcing or corrosion during annual maintenance, cleaning or replacing relays as needed. Review event logs in the 3500/92 136188-02 interface to track relay activation history and identify potential issues with protection logic. Test emergency shutdown sequences annually to ensure relays respond correctly to critical alarm combinations from modules like 3500/33-01-00. Coordinate firmware updates with other system components to maintain compatibility.

Service and guarantee commitment

Bently Nevada provides the 3500/25-01-01-00 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including relay reliability, response time, and integration functionality when used with compatible components like 3500/33-01-00 and 3500/92 136188-02. Our technical support team offers expert guidance on relay logic configuration, safety system design, and troubleshooting protective action sequences.

We offer specialized training on 3500 relay system configuration, including best practices for implementing machinery protection strategies and ensuring compliance with safety standards. Beyond the warranty period, our service agreements include technical support, performance verification, and replacement services to maintain the integrity of your safety-critical relay functions. Bently Nevada’s commitment to quality ensures reliable execution of protective actions throughout the module’s operational lifecycle, backed by our global network of service professionals dedicated to safeguarding your critical machinery assets.