Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/32 125712-01 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System I/O Module |

| Channel configuration | 8 configurable input channels, 4 relay output channels |

| Input type support | 4-20 mA, mV, RTD, thermocouple (Type J/K/T/E/R/S/B) |

| Output rating | 5 A @ 250 VAC, 5 A @ 30 VDC per relay |

| Sampling rate | 100 Hz per input channel |

| Accuracy | ±0.1% of reading (analog inputs), ±0.5°C (temperature inputs) |

| Operating voltage | 5 VDC, ±15 VDC (from 125744-02 rack backplane) |

| Power consumption | 6 W typical, 8 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Compatibility | 125744-02 racks, 140734-01 gateways, 136711-01 sensor cables |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

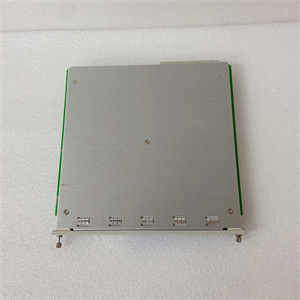

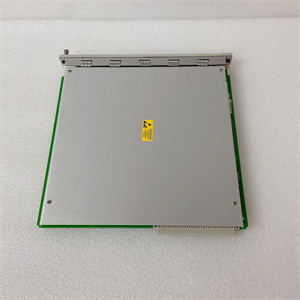

BENTLY 3500/32 125712-01

Product introduction

The 3500/32 125712-01 from Bently Nevada is a versatile input/output module designed to expand the monitoring capabilities of 3500 Machinery Protection Systems. This 1-slot module serves as the critical interface between external sensors, process instruments, and the core protection system housed in 125744-02 racks. Bently Nevada’s 3500/32 125712-01 enables the integration of diverse measurement types—from temperature and pressure to custom process variables—into the unified protection ecosystem, while providing relay outputs for control and alarm actuation.

As a key expansion component, the 3500/32 125712-01 extends the functionality of base 3500 systems by adding flexible input channels that complement vibration data from sensors connected via 136711-01 cables. Its measured values are seamlessly integrated into the system data stream, accessible through 140734-01 communication gateways for both local visualization and enterprise-level analysis. This module empowers users to create comprehensive protection strategies that combine machinery health and process parameters for complete asset monitoring.

Core advantages and technical highlights

Multi-signal integration: The 3500/32 125712-01 supports multiple input types including 4-20 mA loops, mV signals, RTDs, and various thermocouple types, eliminating the need for separate signal conditioning modules. This versatility allows users to integrate temperature, pressure, flow, and other process variables directly into the 3500 protection logic, creating more comprehensive machinery health assessments.

High-accuracy measurement: Equipped with precision analog-to-digital converters, the 3500/32 125712-01 delivers measurement accuracy of ±0.1% for analog inputs and ±0.5°C for temperature measurements. This precision ensures that critical process variables are monitored with the same reliability as vibration data, supporting accurate protection decisions and performance trending.

Configurable relay outputs: The module features four independently configurable relays rated for 5A switching, providing flexible actuation capabilities for alarms, shutdowns, or control functions. Relay logic can be programmed to respond to combined conditions from both the 3500/32 125712-01 inputs and other system modules, enabling sophisticated protection strategies.

Seamless system integration: Designed for plug-and-play installation in 125744-02 racks, the 3500/32 125712-01 automatically communicates with other system components through the backplane. Its data is immediately available to 140734-01 communication gateways and display modules without proprietary interface requirements, simplifying system expansion and configuration.

Typical application scenarios

In power generation turbine systems, the 3500/32 125712-01 installed in 125744-02 racks integrates key process variables with vibration data for comprehensive protection. The module monitors bearing temperatures via RTD inputs, lubrication pressure through 4-20 mA transmitters, and control valve positions, combining these with vibration data from 136711-01 connected sensors. Its relays actuate cooling system adjustments or alarm annunciators based on combined conditions, enhancing turbine protection beyond pure machinery vibration monitoring.

Oil and gas compressor stations utilize the 3500/32 125712-01 to incorporate process parameters into machinery protection logic. The module measures discharge pressure, interstage temperatures via thermocouples, and seal gas flow rates, integrating these with vibration measurements to detect process-induced machinery issues. Its relays trigger shutdown sequences or bypass controls when combined process and machinery conditions indicate potential failure, preventing catastrophic equipment damage.

Manufacturing facilities deploy the 3500/32 125712-01 to connect production line sensors with machinery protection systems in 125744-02 racks. The module monitors motor winding temperatures, hydraulic pressure, and lubricant quality sensors, providing the data needed to distinguish between machinery faults and process-related issues. This integration helps maintenance teams accurately diagnose problems while enabling process-aware protection strategies that minimize unnecessary shutdowns.

BENTLY 3500/32 125712-01

Related model recommendations

125744-02: Rack assembly that houses and powers the 3500/32 125712-01 module.

140734-01: Communication gateway that transmits data from 3500/32 125712-01 to external systems.

136711-01: Sensor cable whose vibration data complements measurements from 3500/32 125712-01.

3500/22M: Power supply module that provides operating power to 3500/32 125712-01 via rack.

3500/60 163179-01: Display module that visualizes data from 3500/32 125712-01 inputs.

3500/42M: Vibration monitor whose data is combined with 3500/32 125712-01 measurements.

3500/15: Auxiliary relay module that extends the output capabilities of 3500/32 125712-01.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/32 125712-01, verify compatibility with the target 125744-02 rack firmware version. Ensure the rack has an available slot and that the power supply can accommodate the additional load. Gather required tools including torque screwdriver, multimeter, and configuration laptop. Inspect the module for shipping damage, particularly checking input/output connectors and backplane pins. Review sensor specifications to confirm compatibility with module input ranges.

Maintenance suggestions: Include 3500/32 125712-01 in quarterly system checks, verifying status LEDs indicate normal operation. Calibrate analog inputs annually using certified standards to maintain accuracy. Test relay outputs during scheduled maintenance by activating them manually and verifying contact operation. Inspect input wiring connections for tightness and corrosion during shutdowns. Keep module firmware updated to ensure compatibility with latest 125744-02 rack features and 140734-01 communication protocols.

Service and guarantee commitment

Bently Nevada provides the 3500/32 125712-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, relay functionality, and communication capabilities. Our technical support team offers expert guidance on configuration, calibration procedures, and integration with 125744-02 racks and 136711-01 sensor systems.

We offer specialized training on I/O module programming, signal conditioning, and protection logic development specific to the 3500/32 125712-01. Beyond the warranty period, our service agreements include calibration verification, technical support, and expedited replacement services to minimize system downtime. Bently Nevada’s commitment to quality ensures reliable performance throughout its operational lifecycle, backed by our global network of service professionals.