Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/33-01-00 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Standard Process Variable Monitor |

| Monitoring channels | 8 configurable process input channels |

| Input type | 4-20 mA, 0-10 VDC, thermocouples (J, K, T, E), RTDs (Pt100) |

| Measurement range | 4-20 mA (0-100% scale); 0-10 VDC; -100°C to +1000°C (temperature) |

| Accuracy | ±0.1% of full scale (electrical); ±0.2°C (temperature) |

| Alarm capability | Configurable dual alarm levels per channel, basic alarm logic |

| Update rate | 50 Hz per channel |

| Communication interface | 3500 system backplane, integrated with 3500/92 136188-02 |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15-05-05-00 power supply) |

| Power consumption | 7 W typical, 9 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

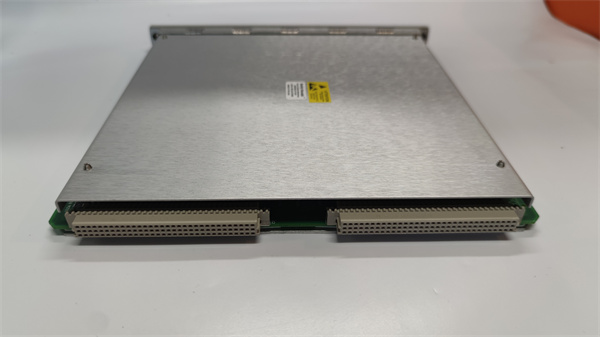

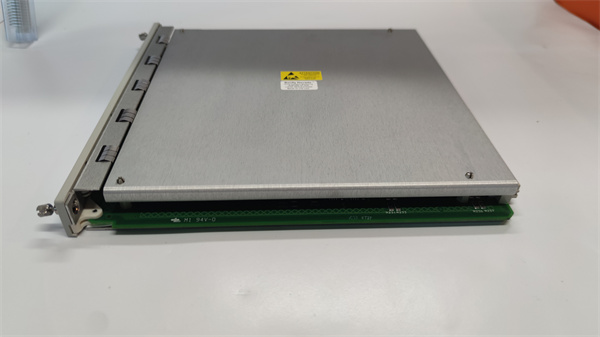

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 3500/15-05-05-00 power modules, 3500/40M 176449-01 vibration monitors |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 3500/33-01-00

Product introduction

The 3500/33-01-00 from Bently Nevada is a standard process variable monitoring module designed to bridge machinery health data with operational process parameters in the 3500 Machinery Protection System. This 2-slot rack-mounted module serves as a versatile data acquisition solution for industrial environments, offering reliable monitoring of temperature, pressure, flow, and other critical process variables through its 8 configurable channels.

Unlike advanced process monitor variants, 3500/33-01-00 is optimized for cost-effective operation in standard industrial settings, providing essential measurement capabilities without the extended temperature ranges or complex diagnostic features required for extreme applications. It integrates seamlessly with core system components like the 3500/15-05-05-00 power supply and 3500/92 136188-02 rack interface, forming a cohesive monitoring ecosystem that links process conditions to machinery performance.

In industrial monitoring architectures, 3500/33-01-00 plays a vital role in creating a unified view of equipment health by correlating process data with vibration and position measurements. Its reliable performance and straightforward configuration make it suitable for medium-complexity applications across manufacturing, power generation, and medium-duty oil and gas facilities, where accurate process monitoring supports both protection and efficiency goals.

Core advantages and technical highlights

Configurable channel flexibility: 3500/33-01-00 features 8 independently configurable channels that support multiple input types—4-20 mA transmitters, voltage signals, common thermocouples (J, K, T, E), and Pt100 RTDs—without requiring hardware modifications. This flexibility allows the module to monitor diverse process variables using the optimal sensor technology for each application, from bearing temperatures via RTDs to flow rates via 4-20 mA transmitters, all within a compact 2-slot design.

Balanced measurement performance: The module delivers reliable accuracy (±0.1% of full scale for electrical inputs and ±0.2°C for temperature) suitable for standard industrial monitoring requirements. This performance ensures detection of meaningful process variations that could impact machinery health, such as temperature increases indicating bearing degradation or pressure fluctuations signaling pump cavitation, without the premium features of higher-precision models.

Efficient power management: Designed to operate with standard 3500 power supplies like 3500/15-05-05-00, 3500/33-01-00 consumes just 7 W typical power, making it energy-efficient in multi-module rack configurations. Its power requirements align perfectly with the capacity of standard power supplies, enabling cost-effective system designs without sacrificing monitoring capabilities.

Basic system integration: The module communicates seamlessly with the 3500/92 136188-02 rack interface via the 3500 backplane, providing time-synchronized process data that correlates with vibration measurements from modules like 3500/40M 176449-01. This integration enables operators to identify relationships between process conditions and mechanical performance, supporting more informed diagnostic decisions and maintenance planning.

Typical application scenarios

In mid-sized manufacturing plants, 3500/33-01-00 modules monitor production line equipment such as conveyor systems, mixers, and packaging machinery. The module tracks motor bearing temperatures via RTDs, hydraulic system pressures through 4-20 mA transducers, and lubrication flow rates, with power supplied reliably by 3500/15-05-05-00 modules. By correlating this process data with vibration measurements through the 3500/92 136188-02 interface, maintenance teams can distinguish between normal operational variations and conditions requiring intervention, reducing unplanned downtime.

Power generation facilities use 3500/33-01-00 to monitor auxiliary equipment like pumps, fans, and compressors, with channels configured for bearing temperatures, discharge pressures, and cooling water flow. The module’s thermocouple inputs track motor winding temperatures, while 4-20 mA channels monitor oil pressure in lubrication systems. Integration with the 3500 system allows operators to correlate these process variables with vibration data, identifying issues like pump wear accelerated by low lubrication pressure.

Medium-duty oil and gas facilities employ 3500/33-01-00 in non-hazardous processing areas to monitor separator pressures, pump suction pressures, and ambient temperatures. The module provides essential process data that, when combined with vibration monitoring from 3500/40M 176449-01 via the central interface, helps operators optimize equipment performance while ensuring safe operation. Its compatibility with standard power supplies like 3500/15-05-05-00 simplifies system deployment in field locations.

BENTLY 3500/33-01-00

Related model recommendations

3500/15-05-05-00: Standard power supply module providing reliable power to this monitor.

3500/92 136188-02: Rack interface module managing and synchronizing this process monitor.

3500/40M 176449-01: Vibration monitor whose data correlates with process variables from this module.

3500/60 163179-01: Display module visualizing integrated process and machinery data.

3500/05-01-02-00-00-01: Serial communication module transmitting process data to legacy systems.

330180-90-00: IEPE accelerometer for vibration data correlation with process parameters.

177230-01-01-05: Shielded extension cable connecting process sensors to this module.

3500/33 149986-01: Advanced process monitor for applications requiring extended capabilities.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/33-01-00, verify the 3500 rack has two adjacent slots available and that a 3500/15-05-05-00 power supply is properly installed to provide 5 VDC and ±15 VDC. For temperature measurements, use appropriate thermocouple extension wires or RTD cabling to maintain accuracy. Route signal cables separately from power wiring to minimize interference, using shielded twisted-pair cables for all analog inputs. Configure channel types and ranges using the 3500/92 136188-02 interface or configuration software to match connected sensors.

Maintenance suggestions: Include 3500/33-01-00 in quarterly system inspections, verifying all 8 channels display stable readings within expected operating ranges. Perform annual calibration verification using calibrated signal generators and temperature references to ensure measurement accuracy. Inspect sensor connections for corrosion or looseness, particularly thermocouple junctions in humid environments. Clean terminal blocks with approved contact cleaner as needed. Review alarm settings semi-annually to ensure they remain appropriate for current operating conditions. Coordinate firmware updates with power supply and interface modules to maintain system compatibility.

Service and guarantee commitment

Bently Nevada provides the 3500/33-01-00 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, alarm functionality, and communication reliability when used with compatible components like 3500/15-05-05-00 and 3500/92 136188-02. Our technical support team offers guidance on sensor selection, channel configuration, and basic process-mechanical data correlation.

We offer training on 3500 process monitoring basics, including installation best practices, calibration procedures, and configuration techniques specific to this standard module. Beyond the warranty period, our service agreements include technical support, calibration services, and replacement options to minimize system downtime. Bently Nevada’s commitment to quality ensures reliable process parameter monitoring throughout the module’s operational lifecycle, backed by our global network of service professionals dedicated to maintaining the integrity of your machinery protection system.