Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/34 |

| Manufacturer | Bently Nevada |

| Product category | Communication Gateway Module |

| Series affiliation | 3500 Machinery Protection System |

| Communication ports | 2× Ethernet (10/100BASE-T), 1× RS-485, 1× USB (configuration) |

| Protocols supported | Modbus TCP/IP, Modbus RTU, OPC UA, Bently Nevada proprietary protocol |

| Data transfer rate | Up to 100 Mbps (Ethernet), 115.2 kbps (RS-485) |

| Operating voltage | 5 VDC, ±15 VDC (powered by 3500/05-01-02-00-00-01 power supply) |

| Power consumption | 8 W typical, 10 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 36 mm (W) × 229 mm (D) (5.2″ × 1.4″ × 9.0″) |

| Protection features | Surge protection, EMI/RFI filtering, watchdog timer |

| Compatibility | 128275-01-E sensor systems, 136188-01 signal modules, 3500/60 displays, SCADA systems |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Security features | SSL/TLS encryption, role-based access control, firewall capabilities |

BENTLY 3500/34

Product introduction

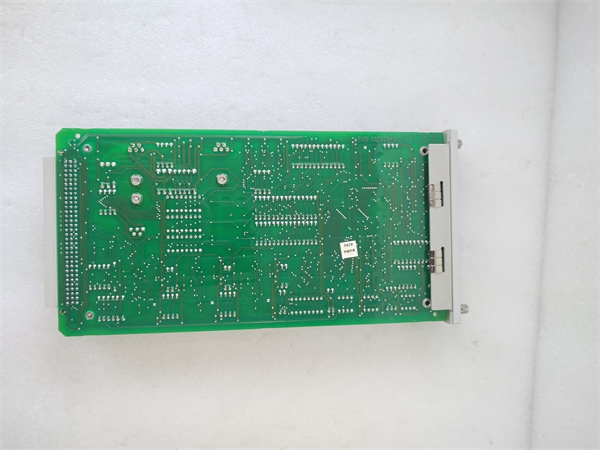

The 3500/34 from Bently Nevada is a high-performance communication gateway module designed as the critical connectivity hub for 3500 Machinery Protection Systems. This rack-mount module serves as the bridge between localized protection system components and enterprise-level monitoring platforms, enabling secure, standardized data transmission from field sensors to control room systems and cloud-based analytics platforms. Bently Nevada’s 3500/34 acts as the communication backbone of the 3500 ecosystem, aggregating measurement data from sensor systems like the 128275-01-E and signal input modules such as the 136188-01, then distributing this information to both local displays like the 3500/60 and remote monitoring systems.

Bently Nevada’s 3500/34 addresses the modern industrial need for seamless data flow between operational technology (OT) and information technology (IT) systems. Its multi-protocol support eliminates communication silos, ensuring machinery health data can be simultaneously used for real-time protection, operator visualization, and long-term analytics. Powered by the 3500/05-01-02-00-00-01 power supply within the 3500 rack, it maintains synchronized operation with all system components while providing secure data access to authorized users across the enterprise.

Core advantages and technical highlights

Multi-protocol flexibility: The 3500/34 supports industry-standard protocols including Modbus TCP/IP, Modbus RTU, and OPC UA, in addition to Bently Nevada’s proprietary protocol. This versatility enables seamless integration with diverse systems—from legacy SCADA platforms to modern cloud-based analytics solutions—without requiring custom interface development.

High-speed data aggregation: The module collects data from up to 256 monitoring points across the 3500 system at rates up to 100 Mbps, ensuring timely transmission of critical measurements from sensors like the 128275-01-E. Its parallel processing capability maintains low latency even when handling simultaneous data requests from multiple clients.

Enterprise-grade security: Incorporating SSL/TLS encryption, role-based access control, and built-in firewall capabilities, the 3500/34 protects sensitive machinery data during transmission and access. This security framework ensures compliance with industrial cybersecurity standards while enabling safe remote monitoring of critical assets.

Redundant communication paths: Equipped with dual Ethernet ports, the module supports redundant network configurations that eliminate single points of failure. Automatic failover ensures continuous data flow even if the primary network path becomes unavailable—critical for maintaining visibility of machinery health in mission-critical applications.

Typical application scenarios

In power generation facilities, the 3500/34 serves as the communication hub for turbine and generator protection systems, aggregating data from 128275-01-E proximity sensors monitoring shaft vibration and position. It transmits this data simultaneously to local 3500/60 displays for operators, to plant DCS via Modbus TCP/IP, and to corporate analytics platforms via OPC UA. This multi-directional data flow supports both immediate operational decisions and long-term asset performance management.

Oil and gas production facilities utilize the 3500/34 to connect distributed compressor station monitoring systems to centralized control centers. The module collects vibration and temperature data from remote 136188-01 modules, then sends critical alarms via Modbus RTU to local PLCs for protection actions while streaming full datasets via Ethernet to enterprise historian systems. Its rugged design ensures reliable operation in the harsh environmental conditions typical of upstream and midstream operations.

Manufacturing plants deploy the 3500/34 to integrate machinery health data with production management systems. The gateway connects to 128275-01-E sensor systems on critical production line equipment, providing real-time vibration data to both the 3500/60 local display and the plant’s MES system via OPC UA. This integration enables condition-based maintenance scheduling that aligns with production plans, maximizing equipment availability while minimizing unplanned downtime.

BENTLY 3500/34

Related model recommendations

128275-01-E (Bently Nevada): Proximity sensor system whose data is transmitted via 3500/34.

136188-01 (Bently Nevada): Signal input module connected to 3500/34 for data aggregation.

3500/60 (Bently Nevada): Display module receiving data through 3500/34 communication.

3500/05-01-02-00-00-01 (Bently Nevada): Power supply for the 3500/34 module.

3500/20 (Bently Nevada): System rack housing the 3500/34 gateway.

163179-01 (Bently Nevada): Extension cable in sensor systems feeding data to 3500/34.

125388-01H (Bently Nevada): Remote HMI receiving data via 3500/34 protocols.

330130-080-00-00 (Bently Nevada): Calibration fixture ensuring data accuracy for transmission.

Installation, configuration and maintenance instructions

Installation preparation: Before installing the 3500/34, verify compatibility with the target 3500/20 rack and ensure firmware versions match other system components. Confirm network infrastructure supports required protocols (Modbus TCP/IP, OPC UA) and bandwidth requirements. Required tools include a screwdriver set, torque wrench, network cable tester, and laptop with configuration software. Inspect the module for shipping damage, particularly checking connector pins and circuit board integrity.

Mounting and wiring: Insert the 3500/34 into an available slot in the 3500/20 rack, securing it with front panel screws torqued to specified values. Power is supplied through the rack backplane from the 3500/05-01-02-00-00-01 module, eliminating the need for external power wiring. Connect Ethernet cables to the primary and redundant network ports, using shielded Cat5e/6 cables with proper grounding. For Modbus RTU devices, connect the RS-485 port to the fieldbus network using twisted-pair cable with surge protection.

Configuration procedures: Power on the 3500 system and establish communication with the 3500/34 using configuration software via USB or network connection. Configure network parameters (IP address, subnet mask, gateway) for Ethernet ports. Define data points to be transmitted, mapping measurements from connected modules like the 136188-01 and sensor systems like the 128275-01-E to appropriate protocol tags. Set up security parameters including user accounts, access levels, and encryption settings. Configure redundancy settings for failover behavior if using dual network paths.

Maintenance suggestions: Include the 3500/34 in quarterly network infrastructure inspections, verifying network link status, error counts, and connection integrity. Monitor module temperature and power consumption through system diagnostics to detect potential issues early. Backup configuration files regularly and store them securely. Check for firmware updates annually and apply during scheduled maintenance windows to ensure compatibility with updated protocols and security standards. Test redundancy failover periodically to confirm proper operation. If communication issues occur, verify network connectivity, protocol settings, and firewall rules before isolating problems to the module.

Service and guarantee commitment

Bently Nevada provides the 3500/34 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including communication functionality and network connectivity. Our technical support team offers specialized guidance on protocol configuration, network integration, and security implementation to ensure seamless data flow between 128275-01-E sensor systems, 136188-01 modules, and enterprise systems.

We offer comprehensive training on the 3500/34‘s advanced features, including protocol mapping, security configuration, and redundancy implementation. Beyond the warranty period, our service agreements include priority technical support, firmware updates, configuration backup services, and expedited replacement options to minimize communication downtime. Bently Nevada’s commitment to quality ensures the 3500/34 delivers reliable communication functionality throughout its operational lifecycle, backed by our global network of service professionals and application engineers.