Description

Detailed parameter table

| Parameter name | Parameter value |

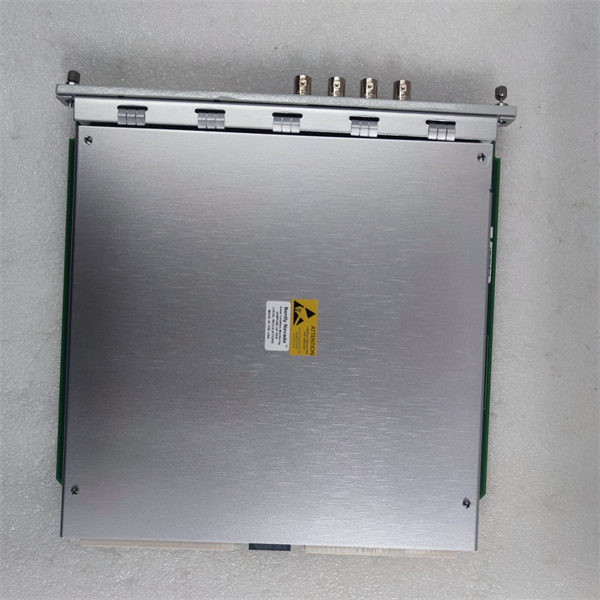

| Product model | 3500/40M 176449-01 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Advanced Vibration Monitor |

| Monitoring channels | 4 independent vibration channels with enhanced processing |

| Input type | Proximity probes, velocity transducers, accelerometers, IEPE sensors |

| Measurement range | ±50 mm peak-to-peak displacement; 0-100 mm/s velocity; 0-1000 m/s² acceleration |

| Frequency range | 0.05 Hz to 20 kHz |

| Accuracy | ±0.05% of full scale |

| Alarm capability | Configurable dual alarm levels, user-defined alarm logic, trend-based alerts |

| Data capture | High-speed waveform recording (256 kS/s), transient capture, spectral analysis |

| Communication interface | 3500 system backplane, Ethernet (10/100 Base-T), integrated with 3500/05-01-02-00-00-01 |

| Operating voltage | 5 VDC, ±15 VDC, +24 VDC (from 3500/15 133292-01 power supply) |

| Power consumption | 10 W typical, 12 W maximum |

| Operating temperature | -10°C to +70°C (-14°F to +158°F) |

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 3500/05-01-02-00-00-01 communication modules, 3500/60 163179-01 displays, all 3500 series modules |

| Certification | UL, CE, RoHS compliant, IEC 61010-1, ATEX, IECEx approved |

BENTLY 3500/40M 176449-01

Product introduction

The 3500/40M 176449-01 from Bently Nevada represents an advanced iteration of vibration monitoring technology within the 3500 Machinery Protection System, engineered to deliver enhanced precision and diagnostic capabilities for critical rotating equipment. This 2-slot rack-mounted module builds upon the foundation of its predecessor while introducing expanded measurement ranges, higher frequency capabilities, and advanced data processing features that make it suitable for the most demanding industrial monitoring applications.

Unlike standard vibration monitors, 3500/40M 176449-01 combines broad sensor compatibility with high-speed data acquisition, enabling both machinery protection and detailed predictive diagnostics in a single unit. It integrates seamlessly with communication modules like 3500/05-01-02-00-00-01 for legacy system connectivity while offering native Ethernet for modern network integration, creating a flexible solution that bridges traditional and advanced monitoring architectures.

In industrial protection strategies, 3500/40M 176449-01 plays a pivotal role in detecting early-stage machinery degradation across a wider range of operating conditions. Its enhanced measurement capabilities and extended environmental tolerance make it ideal for harsh environments in power generation, oil and gas, and heavy manufacturing, where reliable vibration monitoring is essential for preventing unplanned downtime and ensuring equipment safety.

Core advantages and technical highlights

Enhanced measurement performance: 3500/40M 176449-01 delivers superior accuracy (±0.05% of full scale) across an expanded frequency range (0.05 Hz to 20 kHz) compared to previous models, enabling detection of both very low-frequency vibrations (indicative of rotor instability) and high-frequency components (signaling bearing defects or gear issues). The extended measurement ranges accommodate larger displacement, velocity, and acceleration values, making it suitable for monitoring both large slow-speed machinery and high-speed turbomachinery.

Advanced sensor compatibility: The module supports a wider range of sensors including IEPE (Integrated Electronics PiezoElectric) accelerometers, in addition to traditional proximity probes and velocity transducers. This expanded compatibility eliminates the need for external signal conditioning for IEPE sensors, simplifying installation while providing higher fidelity data from modern sensor technologies. Each of the four channels can be independently configured for different sensor types to match specific monitoring requirements.

High-speed data capture: With 256 kS/s (kilosamples per second) waveform capture capability, 3500/40M 176449-01 captures transient vibration events with exceptional detail, enabling precise analysis of short-duration phenomena like impact events, surge conditions, or transient instability. This high-speed acquisition, combined with onboard spectral analysis, allows for detailed post-event diagnostics that help identify the root cause of abnormal vibration patterns.

Robust environmental design: The module operates across an extended temperature range (-10°C to +70°C) and includes enhanced protection against electrical noise and transient voltage events, making it suitable for installation in harsh industrial environments. This rugged design ensures reliable operation in areas with temperature extremes, high electromagnetic interference, or voltage fluctuations, supported by stable power from 3500/15 133292-01.

Typical application scenarios

In combined cycle power plants, 3500/40M 176449-01 modules monitor gas turbine vibration across multiple stages, utilizing its extended frequency range to detect both low-frequency rotor dynamics and high-frequency combustion-related vibrations. The module’s high-speed data capture records transient events during startup and shutdown, while its enhanced accuracy enables precise tracking of vibration trends under varying load conditions. Vibration data is transmitted via Ethernet to plant historians and via 3500/05-01-02-00-00-01 to legacy control systems, providing comprehensive monitoring for both protection and performance optimization.

Offshore oil platforms utilize 3500/40M 176449-01 in subsea compression systems, where its extended temperature tolerance and rugged design withstand harsh marine environments. The module monitors compressor vibration using IEPE accelerometers, detecting early signs of bearing degradation and impeller fouling through high-frequency vibration analysis. Its ability to capture transient events helps diagnose surge conditions in the compression system, enabling proactive adjustments to prevent machinery damage in remote, difficult-to-access locations.

Steel mills employ 3500/40M 176449-01 to monitor rolling mill drives and gearboxes, leveraging its wide frequency range to track both structural vibrations (low frequency) and gear mesh frequencies (high frequency). The module’s enhanced accuracy ensures reliable detection of subtle vibration increases that precede gear failure, while its robust design withstands the high ambient temperatures and electrical noise common in steel production environments. Integration with 3500/60 163179-01 displays provides operators with real-time vibration data alongside process parameters, supporting informed decision-making during production.

BENTLY 3500/40M 176449-01

Related model recommendations

3500/05-01-02-00-00-01: Communication module for legacy system integration with this vibration monitor.

3500/15 133292-01: Power supply module providing stable power for optimal performance.

3500/60 163179-01: Display module for visualizing high-resolution vibration data.

3500/92 136180-01: Rack interface module for centralized configuration and diagnostics.

3500/22M 138607-01: Transient module for extended recording of vibration events.

330180-90-00: IEPE accelerometer compatible with this module’s enhanced sensor inputs.

3500/32M 149986-02: Multi-parameter monitor for correlating vibration with temperature and strain data.

177230-01-01-05: Shielded extension cable for reliable sensor connections in harsh environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/40M 176449-01, verify the 3500 rack has two adjacent slots and that the 3500/15 133292-01 power supply is properly sized to accommodate the module’s power requirements. For IEPE sensors, ensure the module is configured to provide the required excitation voltage (typically 24 VDC). Use shielded twisted-pair cabling (like 177230-01-01-05) for all sensor connections, with shield termination at both ends to minimize noise. Position the rack in a location that maintains ambient temperatures within the -10°C to +70°C range, with adequate ventilation for heat dissipation.

Maintenance suggestions: Include 3500/40M 176449-01 in quarterly system inspections, verifying all channels maintain calibration and stable baseline readings. Perform annual calibration using certified vibration standards that cover the full frequency range (0.05 Hz to 20 kHz). Inspect sensor connections for corrosion, especially in humid or corrosive environments, and clean terminals with approved contact cleaner as needed. Review high-speed waveform captures periodically to identify developing issues not detected by standard alarm thresholds. Coordinate firmware updates with 3500/05-01-02-00-00-01 and other system components to ensure compatibility and access to new diagnostic features.

Service and guarantee commitment

Bently Nevada provides the 3500/40M 176449-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including enhanced measurement accuracy, sensor compatibility, and communication reliability when used with compatible components like 3500/05-01-02-00-00-01 and 3500/15 133292-01. Our technical support team offers specialized guidance on advanced vibration analysis, sensor selection for specific applications, and integration with both legacy and modern control systems.

We offer advanced training on high-frequency vibration analysis, transient data interpretation, and predictive maintenance methodologies tailored to this enhanced module’s capabilities. Beyond the warranty period, our service agreements include priority technical support, calibration services using NIST-traceable standards, and expedited replacement options to minimize downtime. Bently Nevada’s commitment to quality ensures reliable, high-performance vibration monitoring throughout the module’s operational lifecycle, backed by our global network of experts dedicated to protecting your critical machinery assets.