Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/42M 140734-02 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Advanced Vibration Monitor Module |

| Monitoring channels | 4 independent high-resolution vibration channels |

| Input type | Proximity probes (3300/3500 series), velocity transducers, IEPE accelerometers |

| Measurement parameters | Displacement, velocity, acceleration, phase, orbit analysis |

| Measurement range | 0-2000 μm (displacement); 0-50 mm/s (velocity); 0-100 g (acceleration) |

| Frequency range | 0.1 Hz to 15 kHz (baseband); 10 Hz to 20 kHz (high-frequency) |

| Accuracy | ±0.1% of full scale |

| Data capture | 128 kS/s waveform capture, FFT analysis, transient recording |

| Alarm capability | Configurable dual alarm levels per channel, logic-based alarm combinations |

| Communication interface | 3500 system backplane, integrated with 3500/92-02-01-00 interface |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15-05-05-00 power supply) |

| Power consumption | 9 W typical, 11 W maximum |

| Operating temperature | -10°C to +70°C (-14°F to +158°F) |

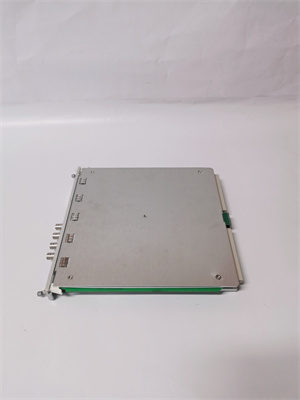

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 3500/92-02-01-00 interface modules, 3500/25-01-01-00 relay modules |

| Certification | UL, CE, RoHS compliant, IEC 61010-1, ATEX, IECEx approved |

BENTLY 3500/42M 140734-02

Product introduction

The 3500/42M 140734-02 from Bently Nevada is a high-performance vibration monitoring module engineered for advanced machinery protection and diagnostic applications within the 3500 Machinery Protection System. This 2-slot rack-mounted module represents a specialized solution for critical rotating equipment, delivering precise vibration measurement, detailed diagnostic data, and comprehensive protection capabilities that go beyond the transmission-focused functionality of modules like the 3500/72M.

Unlike transmitter modules designed primarily for signal distribution, 3500/42M 140734-02 focuses on deep vibration analysis and machinery health diagnostics, providing high-resolution data to both the 3500 system’s central interface (3500/92-02-01-00) and specialized analysis software. It excels at detecting early-stage machinery degradation through advanced signal processing, making it ideal for protecting high-value assets where unplanned downtime would have significant operational and financial impacts.

In industrial monitoring architectures, 3500/42M 140734-02 plays a critical role in predictive maintenance programs by identifying subtle vibration patterns indicative of developing faults. Its robust design and advanced measurement capabilities make it suitable for demanding applications across power generation, oil and gas, and heavy manufacturing industries, where precise vibration analysis is essential for maximizing equipment reliability and lifespan.

Core advantages and technical highlights

Advanced diagnostic capabilities: 3500/42M 140734-02 delivers sophisticated vibration analysis including orbit plots, phase measurements, and high-resolution FFT spectra that provide deep insights into machinery condition—capabilities beyond the basic measurement functionality of 3500/72M. This diagnostic depth enables detection of early-stage faults like bearing degradation, gear misalignment, and rotor imbalance long before they reach critical levels.

High-fidelity data acquisition: With 128 kS/s waveform capture and extended frequency range (up to 20 kHz), the module captures high-frequency vibration components that often indicate incipient failures. This high-resolution data is essential for identifying specific fault signatures, such as bearing defect frequencies or gear mesh anomalies, which would be missed by lower-performance monitoring systems.

Flexible sensor configuration: Each of the four channels can be independently configured for different sensor types, including proximity probes for shaft relative vibration, velocity transducers for general vibration, and IEPE accelerometers for high-frequency measurements. This versatility allows the module to adapt to diverse monitoring requirements across different machinery types within a facility.

Integrated protection logic: Beyond diagnostics, 3500/42M 140734-02 includes advanced alarm functionality with logic-based combinations that trigger protective actions via 3500/25-01-01-00 relay modules. Unlike simple threshold alarms, this intelligent protection can require multiple conditions to be met before initiating shutdowns, reducing false trips while ensuring timely response to genuine threats.

Typical application scenarios

In combined cycle power plants, 3500/42M 140734-02 modules monitor gas turbine shafts using proximity probes to measure radial vibration and thrust position, while accelerometers track bearing housing vibration. The module’s high-frequency analysis detects combustion instability and blade passing frequencies, while orbit plots identify rotor precession issues. Data is transmitted to 3500/92-02-01-00 for centralized monitoring, with critical alarms triggering protective actions via 3500/25-01-01-00 relays to prevent catastrophic failures.

Oil and gas facilities utilize 3500/42M 140734-02 to monitor centrifugal compressors, where the module’s advanced diagnostics distinguish between normal vibration and patterns indicating surge conditions or impeller fouling. Its high-resolution data capture records transient events during startup/shutdown sequences, providing valuable insights for optimizing compressor performance while ensuring protection against damaging operating conditions.

Heavy manufacturing plants employ 3500/42M 140734-02 on critical gearboxes and rolling mill drives, using its phase measurement capabilities to identify misalignment issues and its frequency analysis to detect gear tooth wear. The module’s diagnostic data, integrated with process parameters via 3500/92-02-01-00, helps maintenance teams schedule repairs during planned outages rather than responding to unexpected failures.

3500/42M 140734-02

Related model recommendations

3500/92-02-01-00: Central interface module coordinating diagnostics and alarms.

3500/25-01-01-00: Relay module executing protective actions based on vibration alarms.

3500/15-05-05-00: Power supply module providing stable power to this monitor.

3500/60 163179-01: Display module showing high-resolution vibration data.

330106-05-30-10-02-00: 3300 series proximity probe system for shaft vibration.

330180-90-00: IEPE accelerometer for high-frequency bearing monitoring.

3500/72M: Complementary vibration transmitter for process integration needs.

177230-01-01-05: Shielded cable for reliable sensor connections in harsh environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/42M 140734-02, verify the 3500 rack has two adjacent slots and that a properly sized 3500/15-05-05-00 power supply is installed. For proximity probe installation, ensure proper gap voltage (typically -10 VDC) and alignment with the shaft centerline. Use shielded twisted-pair cables (like 177230-01-01-05) for all sensor connections, with shield termination at both ends. Configure initial channel parameters via 3500/92-02-01-00 to match sensor types and machinery characteristics.

Maintenance suggestions: Include 3500/42M 140734-02 in quarterly predictive maintenance inspections, reviewing trend data and spectral analysis for emerging fault patterns. Perform annual calibration verification using NIST-traceable vibration standards across the full frequency range. Inspect sensor connections for corrosion or 松动,particularly in humid environments. Review alarm thresholds semi-annually to ensure they align with current machinery condition and operational requirements. Coordinate firmware updates with 3500/92-02-01-00 to maintain compatibility and access new diagnostic features.

Service and guarantee commitment

Bently Nevada provides the 3500/42M 140734-02 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, data capture functionality, and integration with compatible components like 3500/92-02-01-00 and 3500/25-01-01-00. Our technical support team offers specialized guidance on vibration analysis, fault diagnosis, and system optimization for critical rotating equipment.

We offer advanced training on spectral analysis interpretation, machinery fault diagnostics, and predictive maintenance methodologies specific to this module’s capabilities. Beyond the warranty period, our service agreements include priority technical support, calibration services using traceable standards, and expedited replacement options to minimize downtime for critical applications. Bently Nevada’s commitment to quality ensures reliable, high-performance vibration monitoring throughout the module’s operational lifecycle, backed by our global network of experts dedicated to protecting your most valuable machinery assets.