Description

Detailed parameter table

| Parameter name | Parameter value |

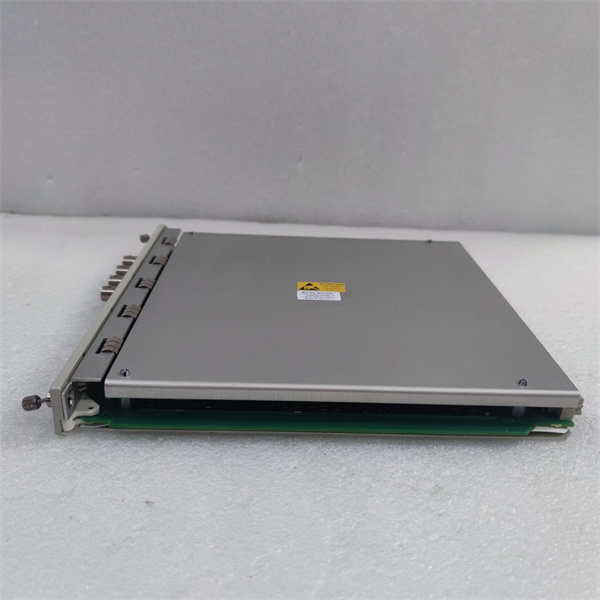

| Product model | 3500/05-01-03-00-00-00 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Communication Interface Module |

| Communication protocols | Modbus RTU, RS-485, 3500 system backplane protocol |

| Data transfer rate | Up to 115.2 kbps (serial); backplane: 10 Mbps |

| Supported modules | All 3500 series monitoring modules |

| Connection ports | 1 x RS-485 (terminal block), 3500 system backplane interface |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15 127610-01 power supply) |

| Power consumption | 4 W typical, 6 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 72 mm (W) × 229 mm (D) (5.2″ × 2.8″ × 9.0″) |

| Compatibility | 3500/42M 176449-02 monitors, 3500/60 163179-01 displays, 3500 racks |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 3500/42M 176449-02

Product introduction

The 3500/05-01-03-00-00-00 from Bently Nevada is a specialized communication interface module designed to facilitate data exchange between the 3500 Machinery Protection System and external devices using serial protocols. This 1-slot rack-mounted module serves as a critical bridge for legacy and serial-based control systems, enabling seamless transmission of machinery health data from monitoring modules like the 3500/42M 176449-02 to SCADA systems, data loggers, and other industrial devices that rely on Modbus RTU communication.

Unlike Ethernet-focused communication modules, 3500/05-01-03-00-00-00 is optimized for serial connectivity, making it ideal for installations where legacy infrastructure remains in place or where long-distance serial communication is required. It integrates natively with the 3500 system backplane, collecting data from vibration, position, and process modules while converting it to industry-standard Modbus RTU protocol for compatibility with a wide range of industrial equipment.

In industrial networks, 3500/05-01-03-00-00-00 plays a vital role in extending the reach of machinery protection data to systems that might not support modern Ethernet protocols. By enabling this connectivity, it ensures that critical vibration and position data from modules like 3500/42M 176449-02 is accessible to both legacy control systems and modern monitoring platforms, supporting comprehensive asset management across power generation, manufacturing, and oil and gas facilities.

Core advantages and technical highlights

Legacy system integration: 3500/05-01-03-00-00-00 specializes in connecting 3500 systems to legacy industrial equipment through its Modbus RTU/RS-485 interface, eliminating the need for costly control system upgrades when implementing machinery protection. This capability is particularly valuable for brownfield installations where existing SCADA or DCS systems rely on serial communication, allowing them to leverage data from advanced monitors like 3500/42M 176449-02 without protocol translation issues.

Reliable serial communication: The module delivers stable, long-distance communication over RS-485 networks, supporting data transmission up to 1200 meters (4000 feet) at lower baud rates—ideal for industrial facilities with distributed machinery. Its robust design includes surge protection and isolation (2.5 kV) to withstand electrical noise and transient voltage events common in industrial environments, ensuring uninterrupted data flow even in harsh conditions.

Backplane data aggregation: 3500/05-01-03-00-00-00 collects data from all connected 3500 modules via the system backplane, including vibration and position measurements from 3500/42M 176449-02, alarms, and diagnostic information. It organizes this data into a Modbus register map that can be easily configured in external systems, providing consistent access to critical machinery parameters without requiring in-depth knowledge of 3500-specific protocols.

Flexible configuration: The module offers configurable baud rates (300 to 115200 bps), parity settings, and data formats to match the requirements of target serial devices. This flexibility ensures compatibility with a wide range of industrial equipment, from legacy data loggers to modern PLCs using Modbus RTU. Configuration can be performed locally via the 3500/60 163179-01 display module or remotely through system software.

Typical application scenarios

In hydroelectric power plants with legacy control systems, 3500/05-01-03-00-00-00 modules connect turbine vibration and position monitoring systems to existing SCADA platforms. The module collects data from 3500/42M 176449-02 monitors tracking generator shaft vibration and turbine position, converting it to Modbus RTU for transmission to the plant’s legacy DCS. This integration allows the existing control system to receive real-time machinery health data without expensive upgrades, supporting both protective actions and maintenance planning.

Paper mills utilize 3500/05-01-03-00-00-00 to connect rotating equipment monitors to production line control systems, which often use serial communication for legacy machinery. The module transmits vibration and position data from 3500/42M 176449-02 modules monitoring dryer rolls and main drives to the mill’s production control system via RS-485. This enables operators to correlate machinery health with production quality, adjusting processes proactively when vibration patterns indicate potential issues that could affect paper quality.

Remote pipeline pump stations employ 3500/05-01-03-00-00-00 for serial communication between pump monitoring systems and remote telemetry units. The module collects data from 3500/42M 176449-02 monitors tracking pump vibration and shaft position, transmitting it over long-distance RS-485 links to telemetry equipment that forwards data to central monitoring centers. This serial connectivity ensures reliable data transmission in remote locations where Ethernet infrastructure may be limited or cost-prohibitive.

BENTLY 3500/42M 176449-02

Related model recommendations

3500/42M 176449-02: Vibration/position monitor whose data is transmitted by this communication module.

3500/60 163179-01: Display module used to configure and monitor this communication interface.

3500/15 127610-01: Power supply module providing regulated power to this interface module.

3500/53 133388-01: Ethernet communication module that complements this serial interface.

3500/22M 138607-01: Transient module whose data is accessible via this communication interface.

177230-01-01-05: Extension cable supporting sensor networks feeding data to this system.

3500/32 125712-01: Multi-parameter monitor whose process data is transmitted via this module.

3500/25 184684-01: Relay module whose status is communicated through this interface.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/05-01-03-00-00-00, verify the 3500 rack has an available slot and a properly sized 3500/15 127610-01 power supply. Prepare RS-485 cabling using twisted-pair shielded wire, ensuring proper termination with 120Ω resistors at both ends of the bus. Route serial cables separately from power wiring to minimize electromagnetic interference. Confirm the installation environment maintains temperatures within 0°C to +60°C with adequate ventilation.

Maintenance suggestions: Include 3500/05-01-03-00-00-00 in quarterly communication system inspections, verifying RS-485 bus integrity and checking for communication errors in system logs. Inspect terminal block connections for corrosion or loosening, especially in humid environments. Test data transmission periodically by comparing values on 3500/60 163179-01 displays with those received by connected serial devices. Update firmware during scheduled maintenance to ensure compatibility with newer 3500 modules like 3500/42M 176449-02. In case of communication issues, check baud rate and parity settings to ensure they match between the module and connected devices.

Service and guarantee commitment

Bently Nevada provides the 3500/05-01-03-00-00-00 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including communication reliability, protocol compliance, and backplane integration when used with compatible 3500 series components like 3500/42M 176449-02 and 3500/15 127610-01. Our technical support team offers expert guidance on serial network configuration, Modbus mapping, and integration with legacy control systems.

We offer specialized training on RS-485 network design, Modbus protocol implementation, and troubleshooting methodologies specific to this communication module. Beyond the warranty period, our service agreements include technical support, firmware updates, and replacement services to ensure continued reliable operation. Bently Nevada’s commitment to quality ensures secure, uninterrupted data transmission between 3500 systems and serial-based industrial equipment, backed by our global network of service professionals dedicated to maintaining the integrity of your machinery protection data.