Description

Key Technical Specifications

-

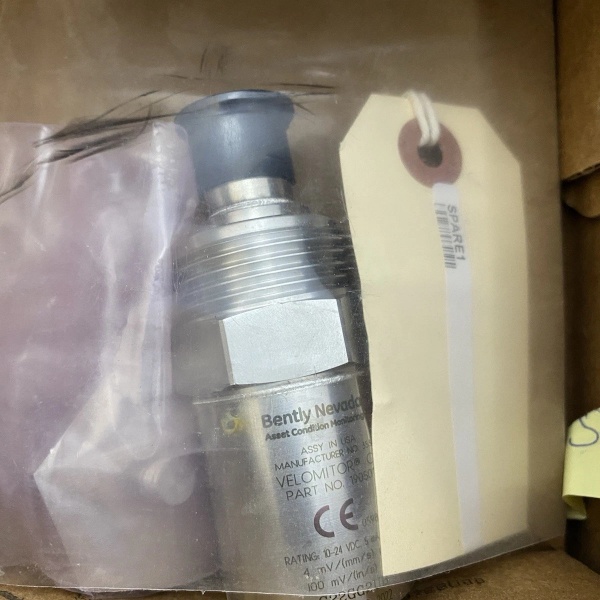

Model Number: 190501-12-00-04

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Measurement Type: Acceleration (vibration)

-

Sensitivity: 10mV/g (±5% tolerance)

-

Measurement Range: ±50g (peak)

-

Frequency Response: 0.5Hz to 10kHz (±3dB)

-

Output Signal: Buffered voltage output (±5V full scale)

-

Target Mounting: 1/4-28 UNF stud (top exit)

-

Operating Temperature: -40°C to +125°C (sensor), -29°C to +66°C (cable)

-

Supply Voltage: Not required (self-generating piezoelectric element)

-

Electrical Isolation: 500Vrms (case-to-signal, per IEC 60664-1)

- Weight: 0.12kg (sensor head only)

Field Application & Problem Solved

In the field, vibration monitoring for pumps, motors, and compressors often fails with contact sensors (wear out) or low-sensitivity units (miss early faults). This accelerometer solves that with a rugged piezoelectric design that survives grease, oil, and high temps. You’ll find it on refinery charge pumps detecting bearing wear, power plant draft fans monitoring imbalance, or paper mill dryer rolls tracking roll eccentricity. Its core value is sensitivity: 10mV/g picks up subtle 0.1g changes (early bearing spalls), while the 10kHz response captures gear mesh frequencies. For example, in a chemical plant’s centrifugal pump, it detected a 0.3g increase in axial vibration—flagging a worn thrust bearing 2 weeks before catastrophic failure. The top-exit connector (12-foot integral cable) also simplifies wiring in tight spaces (e.g., motor topside), cutting installation time by 30% vs. side-exit models.

Installation & Maintenance Pitfalls (Expert Tips)

-

Improper Mounting Torque: Rookies over-tighten the 1/4-28 stud (max 15 ft-lbs), cracking the sensor case. Use a torque wrench—too loose causes resonance (false peaks), too tight risks damage. Apply Loctite 243 to prevent loosening.

-

Ignoring Cable Routing: The integral cable must avoid sharp bends (>90°) or proximity to VFDs (min. 6 inches). Kinks break the internal conductor; VFD noise mimics 5-10kHz vibration. Route along conduit with cable ties.

-

Skipping Baseline Calibration: New sensors drift 1-2mV/g initially. After installation, record baseline vibration (at operating speed) with a Fluke 805. Compare monthly—drift >5% means the crystal is degrading.

-

Mounting on Non-Rigid Surfaces: Attaching to thin motor housings (<1/4 inch) causes “soft foot” resonance. Use a mounting pad (Bently 21000-00) to decouple the sensor from structure-borne noise.

-

Neglecting Temperature Compensation: Above +100°C, sensitivity drops 0.1%/°C. In furnaces or kilns, use the high-temp variant (190501-HT) or install a cooling jacket.

Technical Deep Dive & Overview

The 190501-12-00-04 is a piezoelectric accelerometer from Bently’s 1900 Series, designed for industrial vibration monitoring. It works on the piezoelectric effect: a quartz crystal inside the sensor deforms under acceleration, generating a proportional charge. This charge is buffered by an internal amplifier and output as a voltage signal (10mV/g). The ±50g range covers most machinery faults (e.g., 0.1-5g for imbalance, 5-20g for bearing defects). The 0.5Hz-10kHz frequency response captures both low-frequency imbalance (1-10Hz) and high-frequency bearing tones (1-5kHz). It pairs with Bently 3500/42M monitors or third-party systems (via signal conditioners) to provide acceleration trends (RMS, peak). The top-exit connector (12-foot cable) simplifies routing on vertical shafts. In short, it’s a “canary in the coal mine” for rotating machinery—sensitive enough to catch trouble early, tough enough to last in harsh plants.