Description

330101-00-25-10-02-05: Product Overview

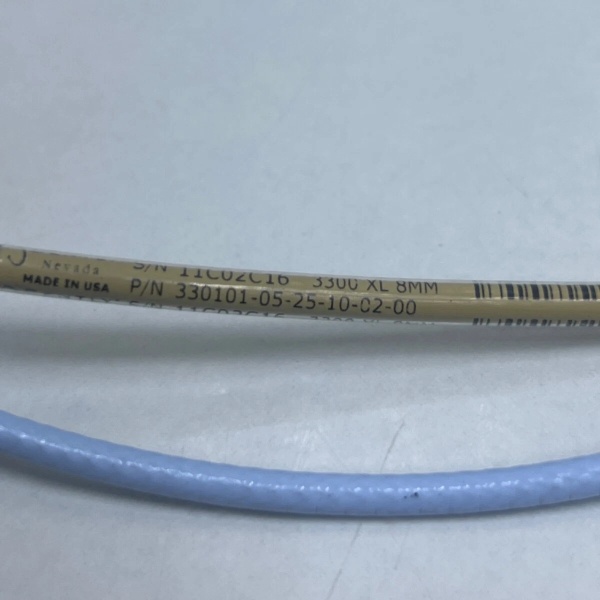

This component is a Proximitor probe within the 3300 XL Proximity Transducer System, designed for non-contact measurement of shaft displacement, vibration, and position in rotating machinery. In an automation system, it serves as the primary sensing element, mounted on machine casings to monitor ferrous targets (e.g., pump shafts, small turbine rotors). It operates by generating a high-frequency electromagnetic field; as a target approaches, eddy currents alter the coil impedance, producing a voltage output proportional to displacement. The 3300 XL system, known for its precision and reliability, integrates this probe with Proximitor signal conditioners (e.g., 330180) and 3500-series monitoring modules (e.g., 3500/42M) to feed data into condition-based maintenance and protection systems (DCS/SIS). The 05 suffix denotes intrinsic safety (Ex ia IIC T4 Ga), enabling deployment in hazardous areas (Zone 0/1) without additional enclosures. This probe enables early detection of wear, imbalance, or misalignment in compact machinery where space constraints limit larger sensors.

Bently Nevada 330101-00-25-10-02-05

330101-00-25-10-02-05: Technical Specifications

-

Model Number: 330101-00-25-10-02-05

-

Manufacturer: Bently Nevada

-

Product Type: Proximitor Probe (Eddy Current)

-

Measurement Range: 0-5 mm (0-197 mils) linear displacement

-

Output Signal: -18V to -2V DC (proportional to target displacement, 1V/2.5mm sensitivity)

-

Probe Length: 2.5 inches (63.5 mm)

-

Thread Size: M10 x 1.5 (metric, for mounting bracket attachment)

-

Target Material: Ferrous metals (steel, cast iron; non-ferrous requires calibration)

-

Operating Temperature: -34°C to +177°C (probe tip), -29°C to +66°C (cable)

-

Connector Type: 7-pin Micro (compatible with 3300 XL Proximitors)

-

Weight: 0.28 kg (probe only)

-

Electrical Isolation: 500Vrms (probe-to-cable, per IEC 60664-1)

-

Hazardous Area Rating: Ex ia IIC T4 Ga (05 suffix denotes intrinsic safety for Zone 0/1)

-

Certifications: CE, ATEX, CSA, IECEx

Core Features & Customer Value

Precision Measurement for Compact Machinery: The probe’s 0-5mm range and 1V/2.5mm sensitivity are optimized for small shafts (e.g., 1-3 inch diameter), resolving displacements as low as 0.1mm. For engineers, this supports predictive maintenance in space-constrained assets like boiler feedwater pumps or auxiliary turbines, where larger probes cannot fit.

Intrinsic Safety for Hazardous Environments: The 05 certification (Ex ia IIC T4 Ga) allows direct installation in Zone 0/1 areas (e.g., refinery compressor skids, chemical plant reactors) without explosion-proof enclosures. This reduces installation costs and complexity while meeting ATEX/IECEx standards.

Robust Mechanical Design: The 2.5-inch length and M10x1.5 thread enable mounting in tight bearing housings. The FEP-insulated cable resists oil, moisture, and abrasion—critical for paper mills or wastewater treatment plants. The 7-pin Micro connector ensures secure, quick-connect wiring, minimizing setup time.

Seamless System Integration: As part of the 3300 XL family, the probe is compatible with all 3300-series Proximitors and 3500 monitoring modules. For procurement managers, this standardization simplifies spares inventory and reduces training overhead.

Low Maintenance Operation: The non-contact eddy current principle eliminates mechanical wear, unlike LVDTs or potentiometers. Annual calibration with a dry-block furnace maintains accuracy, supporting long-term reliability.

Bently Nevada 330101-00-25-10-02-05

Typical Applications

This probe is deployed in compact rotating machinery where space and hazardous area compliance are critical. In power plants, it monitors shaft displacement in boiler feedwater pumps (2.5-inch probe fits between bearing housings) and auxiliary turbines. Refineries use it in catalytic cracker charge pumps, where the 05 certification allows installation in flammable vapor zones. Chemical plants deploy it on reactor agitator shafts, tracking bearing wear via 3500/42M monitors. Wastewater treatment facilities utilize it on submersible pump shafts, withstanding humid, abrasive environments. Its 2.5-inch length also suits small gas turbines (e.g., 5MW) for rotor bow detection during startup.