Description

Key Technical Specifications

-

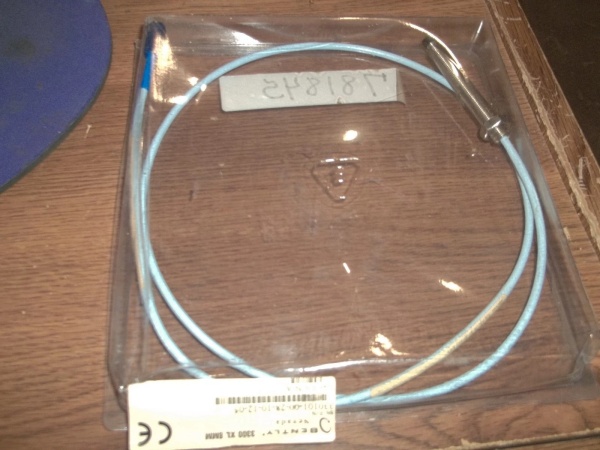

Model Number: 330101-00-28-10-12-05

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Measurement Range: 0-28mm (0-1100 mils) linear displacement

-

Output Signal: -18V to -2V DC (proportional to target displacement, 1V/14mm sensitivity)

-

Frequency Response: 0-10 kHz (covers full spectrum of machinery vibration)

-

Target Material: Ferrous metals (steel, cast iron; non-ferrous requires special calibration)

-

Probe Length: 10 inches (254mm)

-

Thread Size: M10 x 1.5 (metric, for mounting bracket attachment)

-

Operating Temperature: -34°C to +177°C (probe), -29°C to +66°C (extension cable)

-

Supply Voltage: -24V DC (±10%, from 3500 monitor or intrinsically safe power supply)

-

Electrical Isolation: 500Vrms (probe-to-cable, per IEC 60664-1)

-

Hazardous Area Rating: Ex ia IIC T4 Ga (05 suffix denotes intrinsic safety for Zone 0/1)

-

Weight: 0.48kg (probe only)

Field Application & Problem Solved

In the field, large rotating machinery (e.g., 500MW steam turbines, multi-stage compressors) often have wider shaft-to-bearing gaps than smaller equipment—older 18mm-range sensors can’t cover the full orbit, leading to clipped data and missed faults. This 28mm-range sensor solves that with extended linear coverage, capturing full vibration amplitudes without saturation. You’ll find it on hydro turbines monitoring shaft runout, gas compressors tracking thrust collar wear, or generator sets detecting rotor bow. Its core value is twofold: the 28mm range handles larger gaps (typical 0.5-15mm in heavy machinery), and the -18V to -2V output integrates directly with Bently 3500/42M monitors (or legacy 1700 systems) for real-time protection. For example, in a power plant’s boiler feedwater turbine, it detected a 0.3mm shaft shift caused by bearing erosion—flagging the issue 3 weeks before a potential rub. The 05 suffix also makes it intrinsically safe for Zone 0/1 areas (e.g., refinery compressor buildings), eliminating the need for explosion-proof enclosures.

Bently 330101-00-28-10-12-05

Installation & Maintenance Pitfalls (Expert Tips)

-

Incorrect Probe Gap Setting: Rookies set the gap to 1-1.5mm (standard for 18mm sensors), but the 28mm sensor’s optimal initial gap is 1.5-2.0mm. Too tight clips the signal; too wide loses sensitivity. Use a 1.8mm feeler gauge, then fine-tune with the 3500 monitor’s “live trend” view.

-

Ignoring Hazardous Area Wiring: The 05 suffix requires intrinsically safe (IS) cabling (Belden 8761 or equivalent) and barriers. Using standard cable bypasses the IS rating—risk of ignition in explosive atmospheres. Verify barrier ratings match the -24V supply.

-

Skipping Target Surface Inspection: Pitting or scale on large shafts (common in older turbines) distorts the eddy current field. Polish the target area to Ra ≤ 1.6μm (63 micro-inches) with a flap wheel—skip this, and you’ll see 0.1mm measurement drift.

-

Overlooking Cable Routing Near VFDs: The coaxial cable’s shield must be grounded only at the monitor end. Route away from VFDs (min. 12 inches), or use ferrite chokes to suppress 10-100kHz noise that mimics vibration signals.

-

Neglecting Calibration for Large Gaps: At 28mm range, the 1V/14mm sensitivity means a 0.5mm shift = ~35mV output. Use a calibrated simulator (e.g., Bently 9161) to verify linearity—don’t rely on the monitor’s auto-calibrate alone.

Technical Deep Dive & Overview

The 330101-00-28-10-12-05 is a Proximitor eddy current sensor from Bently’s 3300 Series, engineered for large-gap displacement measurement in heavy rotating machinery. It operates on electromagnetic induction: a high-frequency oscillator in the probe generates a magnetic field; as a ferrous target (shaft) moves closer, eddy currents form in the target, altering the probe’s coil impedance. This impedance change is linearly converted to a voltage output (-18V at 28mm gap, -2V at 0mm). The 10-inch probe houses the coil and a 7-pin connector, with an M10x1.5 thread for mounting to a rigid bracket (e.g., Bently 330130). The 28mm range is achieved via a modified coil geometry, sacrificing some sensitivity (vs. 18mm sensors) for extended linearity—ideal for machinery with loose bearings or high thermal growth. It pairs with Bently 3500/42M monitors to provide raw vibration data (peak-to-peak, RMS) and gap voltage trends for predictive maintenance. In short, it’s the go-to sensor for large machines where bigger gaps demand bigger range—rugged, precise, and built for the harshest plant environments.