Description

330102-00-28-05-02-00: Product Overview

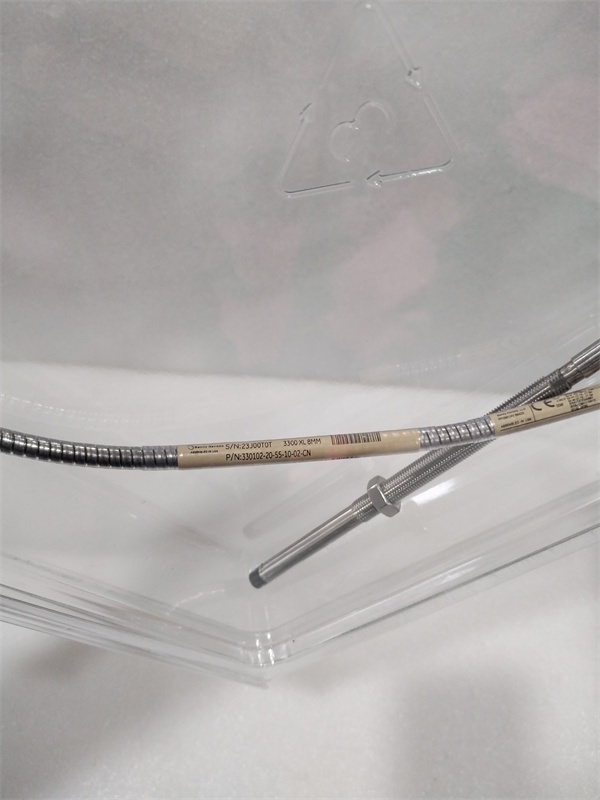

This component is a Proximitor probe within the 3300 Series Proximity Transducer System, designed for non-contact measurement of shaft displacement, vibration, and position in rotating machinery. In an automation system, it serves as the primary sensing element, mounted directly on machine casings to monitor ferrous targets such as pump shafts, small turbine rotors, or compressor impellers. It operates by generating a high-frequency electromagnetic field; when a target approaches, eddy currents alter the coil impedance, producing a voltage output proportional to displacement. The 3300 Series system is recognized for its precision and reliability, forming the basis for condition monitoring in critical assets managed by distributed control systems (DCS) and machinery protection systems (MPS). This probe enables accurate trending of wear, imbalance, or misalignment—critical for preventing unplanned downtime in high-value assets. Its compact 2.8-inch length is specifically suited for applications where space constraints preclude the use of longer probes.

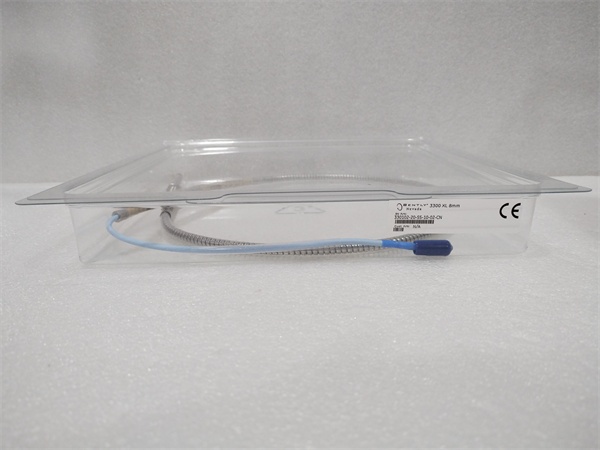

Bently Nevada 330102-00-28-05-02-00

330102-00-28-05-02-00: Technical Specifications

-

Model Number: 330102-00-28-05-02-00

-

Manufacturer: Bently Nevada

-

Product Type: Proximitor Probe (Eddy Current)

-

Measurement Range: 0-10 mm (0-400 mils) linear displacement (dependent on Proximitor)

-

Output Signal: -18V to -2V DC (proportional to target displacement, 1V/5mm sensitivity typical)

-

Probe Length: 2.8 inches (71.1 mm)

-

Thread Size: M10 x 1.5 (metric, for mounting bracket attachment)

-

Target Material: Ferrous metals (steel, cast iron; non-ferrous requires calibration)

-

Operating Temperature: -34°C to +177°C (probe tip), -29°C to +66°C (cable)

-

Connector Type: 2-slot (high-density coaxial)

-

Weight: 0.30 kg (probe only)

-

Electrical Isolation: 500Vrms (probe-to-cable, per IEC 60664-1)

-

Certifications: CE, ATEX, CSA

Core Features & Customer Value

Compact Design for Space-Constrained Applications: The 2.8-inch probe length allows installation in tight bearing housings where larger sensors cannot fit. For engineers working on auxiliary equipment like boiler feedwater pumps or small gearboxes, this eliminates the need for custom mounting solutions.

Standardized Mounting and Connection: The M10x1.5 metric thread is compatible with standard Bently Nevada mounting brackets, ensuring a rigid and repeatable installation. The 2-slot high-density connector provides a secure, low-noise connection to extension cables and Proximitor signal conditioners, reducing setup time and potential wiring errors.

Precise Non-Contact Measurement: The eddy current principle provides high-resolution displacement data without physical contact, eliminating wear and tear common with contact-based sensors. This ensures long-term reliability in harsh environments, such as refineries or paper mills, where contamination and vibration are prevalent.

Seamless System Integration: As part of the 3300 Series family, the probe is compatible with all 3300-series Proximitors (e.g., 330180) and 3500-series monitoring modules (e.g., 3500/42M). For procurement managers, this standardization simplifies inventory and spares planning across diverse machinery.

Cost-Effective Solution for Small Machines: It provides the same high-quality data as larger probes but at a lower cost and in a smaller package, making it an efficient choice for monitoring less critical or smaller-scale rotating equipment.

Bently Nevada 330102-00-28-05-02-00

Typical Applications

This probe is deployed in compact rotating machinery where space limitations and precise measurement are both important. In power plants, it monitors shaft displacement in boiler feedwater pumps and small auxiliary turbines. Refineries use it on charge pumps and small compressor units, where the 2.8-inch length fits between bearing housings. Chemical plants deploy it on reactor agitator shafts and small mixer drives. Wastewater treatment facilities utilize it on submersible pump shafts, withstanding humid, abrasive environments. Its M10x1.5 thread and 2-slot connector also make it a common choice for retrofitting older machinery where the original sensor has been removed. The probe’s compatibility with 3500/42M monitors allows integration into existing Bently Nevada protection systems, providing a unified view of machine health.