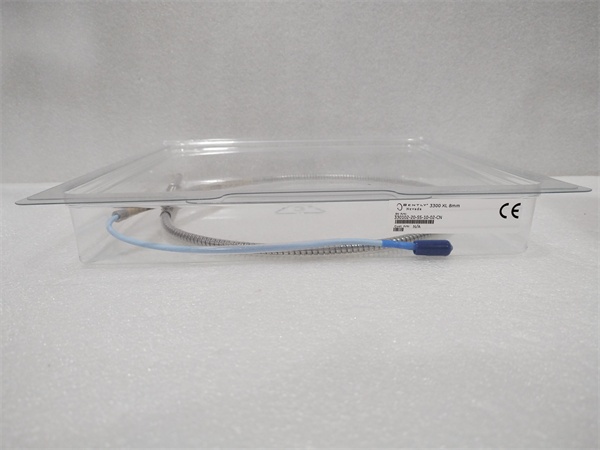

Description

Key Technical Specifications

-

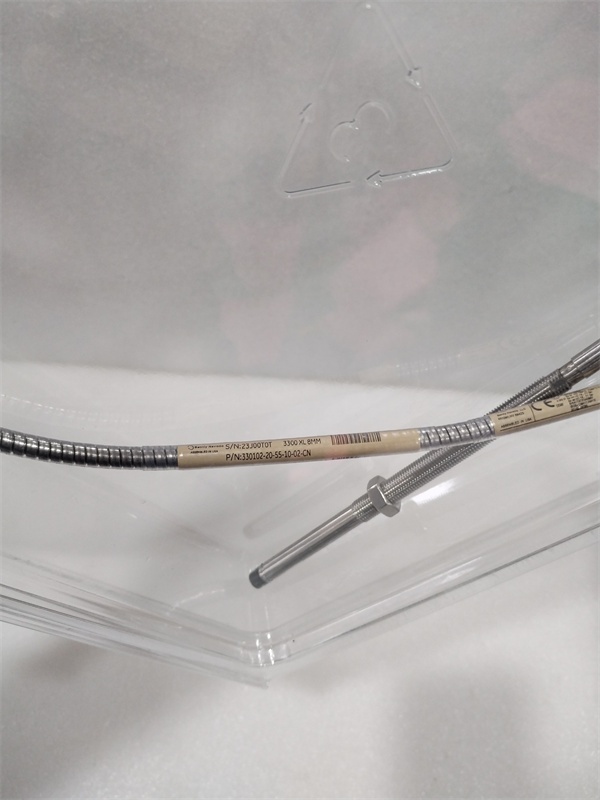

Model Number: 330102-00-72-10-02-05

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Measurement Range: 0-12mm (0-472 mils) linear displacement (extended range for large gaps)

-

Output Signal: -18V to -2V DC (proportional to target displacement, 1V/6mm sensitivity)

-

Frequency Response: 0-10 kHz (covers full spectrum of machinery vibration)

-

Target Material: Ferrous metals (steel, cast iron; non-ferrous requires special calibration)

-

Probe Length: 72 inches (1829mm, extended reach for large machines)

-

Thread Size: M10 x 1.5 (metric, for mounting bracket attachment)

-

Operating Temperature: -34°C to +177°C (probe), -29°C to +66°C (extension cable)

-

Supply Voltage: -24V DC (±10%, intrinsically safe power supply required for Zone 0/1)

-

Electrical Isolation: 500Vrms (probe-to-cable, per IEC 60664-1)

-

Hazardous Area Rating: Ex ia IIC T4 Ga (05 suffix denotes intrinsic safety for Zone 0/1)

-

Weight: 1.2kg (probe only, due to extended length)

Bently 330102-00-72-10-02-05

Field Application & Problem Solved

In the field, large rotating machinery—think 500MW steam turbines, multi-stage compressors, or hydro generators—operate with wider shaft-to-bearing gaps than smaller equipment. Older 18mm-range sensors can’t cover the full orbit, leading to clipped data and missed faults (e.g., bearing erosion, rotor bow). Worse, in hazardous areas (refinery compressor buildings, chemical plant turbine skids), non-rated sensors require bulky explosion-proof enclosures, adding cost and complexity. This extended-range sensor solves both issues. You’ll find it on boiler feedwater turbines (tracking 10mm shaft shifts), gas compressors (monitoring thrust collar wear), or offshore platform generators (detecting rotor imbalance in H2-rich zones). Its core value is dual: the 12mm range captures full vibration amplitudes without saturation, and the 05 certification enables intrinsic safety—no enclosures needed in Zone 0/1. For example, in a Gulf Coast refinery, it detected a 0.5mm shaft migration in a catalytic cracker compressor, flagging bearing failure 4 weeks before rub—all while meeting ATEX Zone 1 requirements. The 72-inch probe reaches deep into large bearing housings where shorter sensors can’t fit.

Installation & Maintenance Pitfalls (Expert Tips)

-

Probe Sag in Extended Lengths: At 72 inches, the probe can sag under its own weight, misaligning the coil with the shaft. Use a rigid mounting bracket (Bently 330130-XL) and torque the M10x1.5 thread to 15 ft-lbs—loose mounting caused a 3mm reading error in a Louisiana turbine.

-

Intrinsic Safety Wiring Neglect: The 05 suffix mandates intrinsically safe (IS) cabling (Belden 8761) and barriers. Standard cable bypasses the rating—risk of ignition in Zone 0/1. Verify barrier power limits (max 250mW) match the -24V supply; a Texas plant once fried a barrier by exceeding this.

-

Gap Setting for Extended Range: Rookies use the 1-1.5mm gap for smaller sensors. For 12mm range, set initial gap to 1.2-1.5mm (feelar gauge). Too wide misses 0.2mm shifts; too tight risks rubbing in large clearances. Fine-tune with the 3500 monitor’s live trend.

-

Target Surface Contamination: Large shafts (e.g., 12-inch diameter) accumulate scale/pitting. Polish the target to Ra ≤ 1.6μm (63μin) with a flap wheel—pitting adds 0.1mm error, masking real displacement. A West Virginia generator had false trips until we cleaned the shaft.

-

Cable Routing Near Heat Sources: The 72-inch cable passes near turbine casings (200°C+). Use high-temp cable (Bently 3300-TG) or shield with ceramic sleeving—melting insulation caused a short in a Canadian plant.

Bently 330102-00-72-10-02-05

Technical Deep Dive & Overview

The 330102-00-72-10-02-05 is a Proximitor eddy current sensor from Bently’s 3300 Series, engineered for large-gap displacement measurement in hazardous-area machinery. It operates on electromagnetic induction: a high-frequency oscillator in the 72-inch probe generates a magnetic field; as a ferrous shaft moves closer, eddy currents form in the target, altering the coil’s impedance. This change is linearly converted to a -18V to -2V output (1V/6mm sensitivity), covering 0-12mm gaps. The extended 72-inch length uses a reinforced cable assembly to prevent sag, while the M10x1.5 thread ensures rigid mounting. The 05 suffix adds intrinsic safety (Ex ia IIC T4 Ga) via galvanic isolation and power limitation, capping spark energy at 250mW for Zone 0/1. It pairs with Bently 3500/42M monitors to provide shaft orbit plots and displacement trends—critical for large-machine predictive maintenance. In short, it’s the “long arm” of the 3300 system: reaching deep into large machines, measuring precisely, and staying safe in explosive atmospheres.