Description

Key Technical Specifications

-

Model Number: 3500/05 130768-01

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Function: Rack backplane interface (slot management, data routing, power distribution)

-

Supported Slots: Up to 16 half-height or 8 full-height 3500 series modules per rack

-

Backplane Protocol: Proprietary high-speed serial (for module-to-module communication)

-

Power Distribution: 24V DC (from 3500/15 power supply), 150W total capacity per rack

-

Redundancy: Supports dual 3500/15 power supplies (load-sharing, failover)

-

Hot-Swap Support: Yes (module replacement without rack shutdown)

-

Operating Temperature: 0°C to +65°C (rack-mounted)

-

Storage Temperature: -40°C to +85°C

-

Dimensions: 483mm x 25mm x 305mm (WxHxD, full rack width, half-height)

-

Weight: 0.85kg

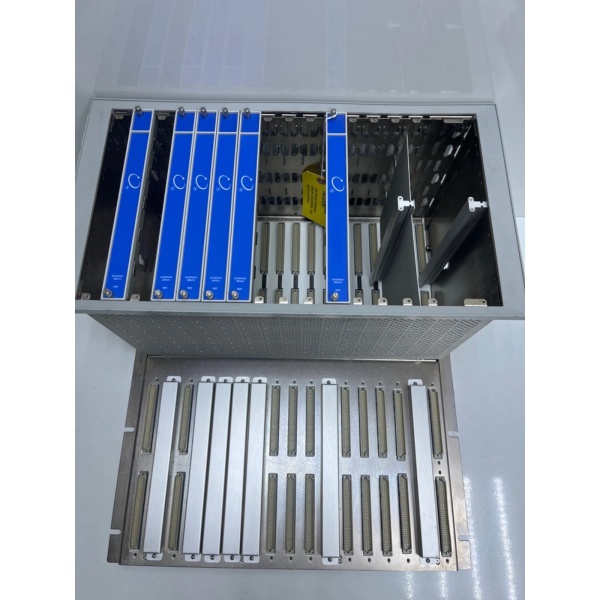

Bently Nevada 3500/05 130768-01

Field Application & Problem Solved

In the field, the 3500 Monitoring System’s strength lies in its modularity—but without a stable rack interface, that modularity falls apart. I’ve seen plants lose entire protection networks because a loose backplane connection caused intermittent communication between vibration monitors (3500/42M) and keyphasor modules (3500/25), or a single power feed failure took down half the rack. This interface module solves that by acting as the “central nervous system” of the 3500 rack. It manages slot assignments (ensuring modules like power supplies, monitors, and comms are in the right order), routes data via the backplane bus, and distributes 24V DC power from redundant 3500/15 supplies. You’ll find it in power plants housing turbine protection racks, refineries integrating compressor monitors, or paper mills linking 3500 systems to DCS. Its core value is reliability: dual power support means no single point of failure, and hot-swap capability allows replacing a faulty module without shutting down the entire protection system. For example, in a Gulf Coast gas plant, it prevented a 12-hour outage by maintaining communication between modules during a 3500/42M monitor swap—something the old fixed-backplane design couldn’t do.

Installation & Maintenance Pitfalls (Expert Tips)

-

Incorrect Slot Sequencing: Rookies place communication modules (3500/92) before power supplies (3500/15), causing boot failures. Always follow 3500 manual slot priority: power first, then communication, then monitors. Use the 3500 Configuration Software to auto-validate slot order.

-

Loose Backplane Connectors: Vibration from nearby pumps loosens the 3500/05’s backplane fingers over time. Inspect quarterly—wiggle each module to check for play. Tighten the rack’s mounting screws if the entire assembly shifts.

-

Ignoring Redundant Power Testing: Dual 3500/15 supplies share the load, but leaving one unplugged disables redundancy. Pull the primary supply’s cord while watching the 3500 rack LEDs—secondary should take over in <100ms. If not, check the “parallel” dip switch.

-

Poor Rack Grounding: The 3500/05’s backplane relies on a single ground point. Ensure the rack is bonded to the plant’s main ground grid (≤1 ohm resistance). I’ve fixed “phantom trips” in steel mills by improving rack grounding.

-

Outdated Firmware Risks: The 130768-01 firmware fixes a rare “slot conflict” bug (v3.5 and earlier). Update via Bently Update Manager—unpatched modules may reject new 3500/42M revisions.

Bently Nevada 3500/05 130768-01

Technical Deep Dive & Overview

The 3500/05 130768-01 is the rack interface module for Bently’s 3500 Monitoring System, serving as the physical and logical hub for the entire framework. Physically, it spans the full width of the 19-inch rack, with backplane connectors that mate with every 3500 module slot. Logically, it assigns each module a unique address, routes data (alarms, trends, configuration) via a proprietary serial bus, and distributes 24V DC power from the 3500/15 supplies. Internally, it uses a microcontroller to manage slot mapping and a power switch matrix for load sharing. The 130768-01 variant adds enhanced error checking for backplane data (CRC validation) and improved power monitoring (reports voltage sag/droop to the 3500/15). It works with all 3500 series modules—monitors, keyphasors, TDIs, and gateways—by enforcing the framework’s electrical and protocol standards. In short, it’s the “backbone” of the 3500 system—without it, the modular design collapses into a pile of uncoordinated parts.