Description

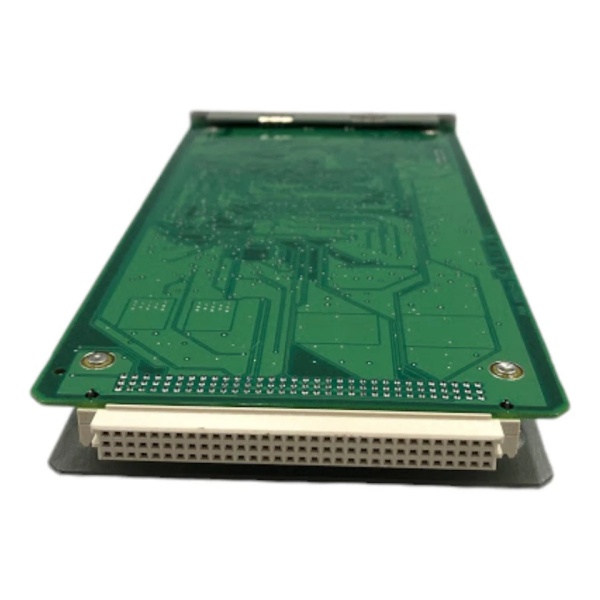

3500/25-02-01-00-00: Product Overview

The Bently Nevada 3500/25-02-01-00-00 is a 2-channel Keyphasor Module designed for the 3500 Machinery Protection System. A keyphasor is an essential once-per-revolution timing signal derived from a rotating shaft, used as a phase reference for advanced vibration analysis. This module accepts input from eddy current proximity probes (with a keyphasor tip), magnetic pickups (MPUs), or geartooth sensors, converts the raw signal into a clean, buffered pulse, and distributes it to other monitoring modules in the 3500 rack (such as the 3500/42M Vibration Monitor). The “-02-” in the model number indicates it has two independent channels, allowing it to monitor the speed of two separate shafts simultaneously (e.g., in a multi-spool turbine). The “01-00-00” configuration denotes specific internal termination options and a standard hardware setup. By providing reliable phase data, the 3500/25-02-01-00-00 enables critical diagnostic tools like full spectrum plots, Bode plots, and polar plots, which are indispensable for identifying complex faults like rotor rub, misalignment, and aerodynamic instability.

3500/25-02-01-00-00

3500/25-02-01-00-00: Technical Specifications

-

Model Number: 3500/25-02-01-00-00

-

Manufacturer: Bently Nevada (a Baker Hughes Business)

-

Product Type: Keyphasor Module (Machinery Protection)

-

Number of Channels: 2 independent keyphasor inputs

-

Transducer Compatibility:

-

Proximity Probes: 3300 XL, 3300 NSv, and other eddy-current probes with a keyphasor tip (generates a digital pulse)

-

Magnetic Pickups (MPUs): Standard 3300 series or equivalent (generates a sine wave)

-

Geartooth Sensors: For ferrous gears

-

-

Input Signal Range:

-

Proximity Probe: Digital pulse (>+6V threshold)

-

MPU: Sine wave (0.5 Vrms to 30 Vrms, 1 Hz to 20 kHz)

-

-

Output Signal: Buffered keyphasor pulse (TTL-compatible) transmitted to the 3500 rack backplane for use by other modules

-

Internal Termination: Configurable via board jumper (options typically include 50 Ω, 100 Ω, 200 Ω, or no termination); the “01” in the model number specifies a default termination setting.

-

Configuration: Via 3500 Configuration Software (defines sensor type, gap voltage, etc.)

-

Supply Voltage: 24V DC (±10%), sourced from the 3500 Power Supply Module

-

Operating Temperature: 0°C to +65°C (rack-mounted, IEC 60068-2-1/2 compliant)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Dimensions: 119mm (H) x 25mm (W) x 102mm (D) (3500 half-height slot)

-

Weight: 0.16 kg (rack-mountable)

-

Certifications: CE, UL/cUL Listed, ATEX Zone 2 (optional), IECEx

Core Features & Customer Value

Dual-Channel Phase Detection: With two independent channels, the 3500/25-02-01-00-00 can monitor the rotational speed of two separate shafts, such as the high-pressure and low-pressure spools in a gas turbine. This is critical for synchronizing vibration data from multiple rotors, enabling accurate cross-channel analysis.

Support for Multiple Sensor Types: The module is flexible and works with both proximity probes (which offer high resolution and can be installed near the shaft) and magnetic pickups (which are robust and suitable for high-temperature environments). This versatility simplifies integration into existing machinery setups.

Essential for Advanced Diagnostics: Phase information provided by the keyphasor is not available from simple vibration amplitude readings. It is crucial for performing tasks like balancing rotating components, diagnosing synchronous and non-synchronous vibrations, and analyzing rotor dynamics. Without a keyphasor, these advanced diagnostic capabilities are lost.

Seamless System Integration: The module operates transparently within the 3500 rack. Once configured, it automatically supplies keyphasor signals to any other module that requires them, such as the 3500/40M, /42M, /44M, etc., without additional wiring.

Configurable Signal Conditioning: The ability to configure internal termination resistors ensures signal integrity by matching the impedance of the connected sensor and cabling, preventing signal reflections that could lead to erroneous readings.

3500/25-02-01-00-00

Typical Applications

The 3500/25-02-01-00-00 is fundamental for any application requiring phase-based vibration analysis:

-

Power Generation: Steam turbines (monitoring HP, IP, and LP rotors), gas turbines (compressor and turbine sections), and generators (rotor speed reference).

-

Oil & Gas: Centrifugal compressors (multi-stage shafts), gearboxes (input and output shafts), and expanders.

-

Aerospace & Marine: Jet engines, ship propulsion turbines, and auxiliary power units (APUs).

-

Industrial Manufacturing: Paper machine dryer sections (multiple rolls), steel mill drives, and large pumps/motors with coupled shafts.

In a steam turbine, for example, one channel of the 3500/25-02-01-00-00 might be connected to a proximity probe on the high-pressure rotor, while the second channel monitors the low-pressure rotor. This setup allows engineers to correlate vibration events across both rotors relative to their own rotation, simplifying the diagnosis of complex interactions like blade passing frequency vibrations.