Description

Key Technical Specifications

-

Model Number: 3500/25-02-01-01

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Channels: 2 independent (software-configurable for keyphasor or speed input)

-

Input Type: Eddy current pickups (e.g., 3300 Series Proximitors), magnetic pickups (variable reluctance), TTL/CMOS digital pulses

-

Input Frequency Range: 0-25 kHz (covers 0-150,000 RPM at 60 pulses/rev)

-

Output Signal: Digital pulse train to 3500 framework (via rear transition module)

-

Supply Voltage: 24V DC (±10%, from 3500 rack power supply)

-

Operating Temperature: 0°C to +65°C (rack-mounted)

-

Storage Temperature: -40°C to +85°C

-

Electrical Isolation: 500Vrms (channel-to-rack, per IEC 60664-1)

-

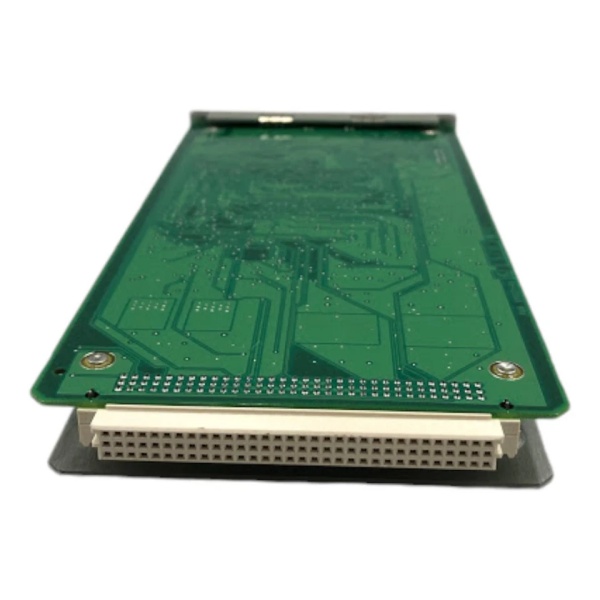

Dimensions: 119mm x 25mm x 102mm (WxHxD, 3500 half-height slot)

-

Weight: 0.15kg

Bently 3500/25-02-01-01

Field Application & Problem Solved

In the field, rotating machinery protection relies on synchronized vibration data—but without a stable keyphasor (phase reference) signal, FFT analysis becomes useless. Older single-channel keyphasor modules force technicians to daisy-chain sensors or accept gaps in coverage. This 2-channel module solves that by providing redundant phase references for critical machines. You’ll find it on steam turbines (synchronizing 360° vibration plots), gas compressors (tracking blade pass frequency), or generators (detecting rotor winding faults). Its core value is precision: it locks onto shaft keyway/pulse wheel edges with <1° phase error, even at 10,000 RPM. For example, in a refinery’s catalytic cracker compressor, it eliminated “phase drift” alarms caused by a failing single-channel module—cutting false trips by 90%. The dual channels also allow backup: if one pickup fails, the second keeps the system online until maintenance.

Installation & Maintenance Pitfalls (Expert Tips)

-

Wrong Pickup Air Gap: Magnetic pickups need 0.5-1.5mm gap (per spec sheet); eddy current probes (if used) need 1-2mm. Set too wide, and you lose signal; too tight, and you risk rubbing. Use a non-ferrous feeler gauge—neversteel.

-

Reversed Signal Polarity: If the keyphasor signal is inverted (e.g., rising edge instead of falling), phase data flips 180°. Verify polarity with a scope: the 3500/25 expects a positive-going pulse at TDC (top dead center). Swap pickup wires if needed.

-

Ignoring Shield Grounding: Coaxial cables for magnetic pickups must have shields grounded only at the rack end. Grounding at both ends creates 60Hz hum, which mimics a valid pulse at 3600 RPM. Tape exposed shields with conductive tape near VFDs.

-

Mismatched Pulse Wheel Teeth: The module assumes a standard pulse wheel (e.g., 1 tooth/rev for speed, 60 teeth/rev for phase). If the wheel has 30 teeth, you’ll get double the frequency—adjust the 3500 configuration to “teeth per rev” to fix scaling.

-

Skipping Diagnostic Logs: The 3500/25 logs “signal loss” or “noise” faults. Check these weekly—intermittent noise often precedes pickup failure (e.g., cracked magnetic tip). Replace proactively.

Bently 3500/25-02-01-01

Technical Deep Dive & Overview

The 3500/25-02-01-01 is a dual-channel keyphasor module for Bently’s 3500 Machinery Protection System. It acts as a signal conditioner: raw pulses from shaft-mounted pickups (magnetic/eddy current) are amplified, filtered (to remove EMI), and converted to digital signals. Each channel handles 0-25kHz inputs—enough for 150,000 RPM at 60 pulses/rev. The module interfaces with the 3500 rack via a rear transition module (e.g., 3500/92), sending phase data to processors (3500/42M, 3500/44M) for vibration analysis. Internally, it uses a Schmitt trigger to clean noisy signals and a counter to measure pulse frequency (for speed). Redundant channels mean if one fails, the other takes over—critical for 24/7 plants. In short, it’s the “metronome” of the 3500 system—keeping all vibration data in sync, so you know exactly whenand wherea machine is shaking.