Description

Key Technical Specifications

-

Model Number: 3500/61-05-01 136711-02

-

Manufacturer: Bently Nevada (Baker Hughes)

-

Input Channels: 6 independent (configurable for RTD: Pt100/Pt1000; TC: J/K/T/E)

-

Input Impedance: ≥10 MΩ per channel (minimizes signal attenuation)

-

Accuracy: ±0.13% of full scale (superior to standard ±0.5% modules)

-

Alarm Outputs: 2 per channel (Alert/Warning, Danger/Trip; 1-60 sec adjustable delay)

-

Recorder Output: 4-20mA per channel (linear to temperature, for trend logging)

-

Operating Temperature: -30°C to +65°C (industrial environment tolerance)

-

Isolation: 250Vdc channel-to-channel (05 suffix denotes enhanced isolation)

-

Power Consumption: 9W nominal (low load on 3500 rack power supply)

-

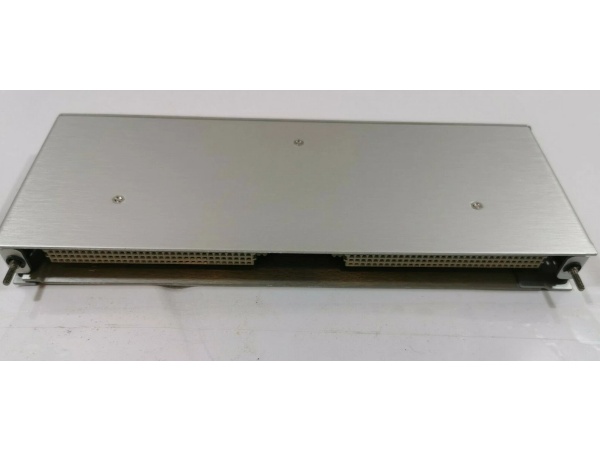

Dimensions: 241mm (H) x 24mm (W) x 242mm (D) (fits 3500 half-height slot)

-

Weight: 0.91kg (lightweight for rack mounting)

-

Firmware Variant: 136711-02 (adds automated calibration drift compensation)

Bently 3500/61-05-01 136711-02

Field Application & Problem Solved

In the field, temperature monitoring for critical machinery—turbines, generators, reactors—is a high-stakes game. The biggest challenge is getting accurate, reliable data without false alarms from EMI or sensor drift. Older single-channel modules or non-isolated units often miss subtle overtemp trends (like bearing lubrication failure) or trip unnecessarily due to ground loops in refineries. This 6-channel module, with the 136711-02 firmware, solves that by packing precision, isolation, and stability into one unit. You’ll find it on power plant turbine bearings (tracking lube oil temp), refinery catalytic crackers (monitoring reactor tubes), or generator stator windings (preventing insulation burnout). Its core value is twofold: ±0.13% accuracy catches 0.5°C shifts early (critical for turbine blades), and 250Vdc channel isolation kills noise from nearby VFDs or motors—something I’ve seen save a paper mill $100k in avoided downtime by stopping phantom “overtemp” trips. The 136711-02 firmware adds automated drift compensation, reducing annual calibration needs by 30% in chemical plants. The 4-20mA recorder output also feeds plant historians, letting engineers correlate temp spikes with process changes.

Installation & Maintenance Pitfalls (Expert Tips)

-

Wrong Sensor Wiring: Rookies mix up RTD (3/4-wire) and TC (polarity-sensitive) connections. For RTDs, always use 3-wire minimum to cancel lead resistance; for TCs, verify polarity with a multimeter—reverse wires and you’ll get negative temps. Label each sensor type on the terminal block.

-

Ignoring Shield Grounding: RTD/TC cables need shielded twisted-pair, but grounding at both endscreates ground loops. Ground shields only at the 3500 rack(not the sensor). In a Gulf Coast refinery, this mistake caused 60Hz hum in temps, masking a real 10°C rise.

-

Skipping Calibration Leveraging Firmware: The 136711-02 firmware automates drift tracking. Still, calibrate annually with a dry-block furnace (e.g., Fluke 9171). Compare module readings to a calibrated RTD—drift >0.2% means the ADC needs service.

-

Overlooking Alarm Thresholds: Setting Alert too close to normal temp (e.g., 5°C margin) causes nuisance trips during load swings. Use historical data to set thresholds 10-15°C above steady-state, and enable 30-sec delay for transients.

-

Neglecting Isolation Checks: The 250Vdc isolation degrades over time. Every 2 years, test with a megger—if <250Vdc, replace the module. I’ve seen a steel mill module fail this test, letting motor noise corrupt temp data.

Bently 3500/61-05-01 136711-02

Technical Deep Dive & Overview

The 3500/61-05-01 136711-02 is a 6-channel temperature monitor for Bently’s 3500 Machinery Protection System, engineered for precision in harsh environments. It acts as a signal conditioner and analyzer: raw RTD/TC signals enter via terminal blocks, are amplified/filtered (to remove EMI), and digitized by 16-bit ADCs. For RTDs, it applies Callendar-Van Dusen equations to convert resistance to °C; for TCs, it uses polynomial approximations. The 250Vdc channel isolation (via optocouplers) prevents cross-talk in noisy environments. The 136711-02 firmware enhances this with automated drift compensation—tracking sensor aging and adjusting readings in real time, critical for refineries with long sensor lifecycles. Processed data is compared to user-set thresholds (Alert/Danger), triggering relay contacts for alarms. Simultaneously, it outputs 4-20mA signals proportional to temp for plant recorders. It mounts in a 3500 rack, drawing 24V DC from the 3500/15 power supply, and communicates status via the backplane to 3500/92 gateways. In short, it’s the “thermometer” for your most critical machines—precise enough to catch trouble, tough enough to survive the plant floor, and smart enough to reduce maintenance overhead.