Description

1. Detailed parameter table

| Parameter name | Parameter value |

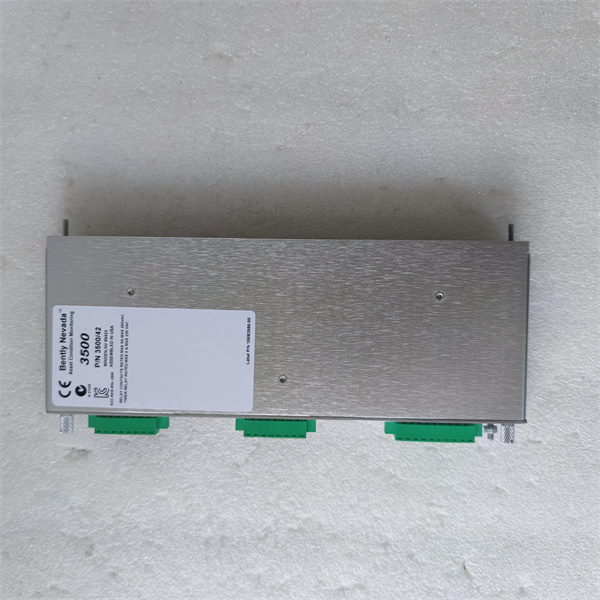

| Product model | 128229 – 01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Proximitor Seismic I/O Module, part of the 3500/42M series |

| Series | 3500/42M |

| Input type | Accepts input from proximity and seismic transducers |

| Output type | Provides various vibration and position measurements, and outputs alarm signals based on user – programmable alarms |

| Channel number | Four – channel monitor |

| Power consumption | 8.25 watts typical |

| Storage temperature | – 40 °C to + 85 °C |

| Operating temperature | – 30 °C to + 65 °C |

| Weight | Approximately 300 g (as per some sources, may vary slightly) |

| Dimensions | 2.5 x 11.2 x 24.2 cm |

| Certification | Meets industry – relevant safety and quality standards, though specific certifications may need to be confirmed with BENTLY NEVADA directly. Likely compliant with standards related to industrial monitoring equipment |

| Termination type | Internal terminations, which simplify installation and reduce wiring complexity |

| Mounting option | Designed to be installed within a relevant industrial monitoring rack system, such as the 3500 series rack |

BENTLY 128229-01

2. Product introduction

The BENTLY NEVADA 128229 – 01 is a high – performance Proximitor Seismic I/O Module, belonging to the well – regarded 3500/42M series. Engineered with precision and expertise, this module plays a pivotal role in industrial machinery health monitoring. It serves as a crucial interface that can receive signals from both proximity and seismic transducers, process these signals, and then output valuable data related to machinery vibrations and positions. This data is essential for maintaining the optimal performance and safety of industrial equipment, making the 128229 – 01 a go – to choice for industries that rely on accurate and reliable machinery condition assessment.

3. Core advantages and technical highlights

Multi – channel and versatile signal processing: With four channels, the 128229 – 01 can simultaneously handle inputs from multiple proximity and seismic transducers. It has advanced signal – conditioning capabilities, which are able to process the incoming signals to provide highly accurate vibration and position measurements. These measurements cover a wide range of parameters, including radial vibration, thrust position, differential expansion, eccentricity, and more. This versatility allows it to be used in a variety of industrial machinery, from large – scale turbines to precision – engineered manufacturing equipment. By accurately measuring these parameters, it enables early detection of potential machinery issues, such as misalignment, bearing wear, or abnormal vibrations, which can prevent costly breakdowns and extended downtime.

User – programmable alarm system: One of the key features of the 128229 – 01 is its user – programmable alarm functionality. Operators can set specific alarm thresholds based on the normal operating parameters of their machinery. The module continuously compares the measured values of vibrations and positions against these pre – set alarm setpoints. When the measured values exceed the set thresholds, it immediately triggers an alarm. This real – time alarm system is invaluable for ensuring the safety and reliability of industrial processes. It gives operators the ability to take immediate corrective actions, such as shutting down the equipment for maintenance or adjusting the operating conditions, before a minor issue escalates into a major failure.

Robust construction for harsh environments: Constructed with high – quality materials, the 128229 – 01 is designed to withstand the harsh conditions often found in industrial environments. It can endure exposure to extreme temperatures, high humidity, and mechanical vibrations without compromising its performance. The module’s internal components are well – protected, ensuring long – term reliability and minimal downtime. This robust construction makes it suitable for use in industries such as oil and gas, power generation, mining, and manufacturing, where equipment is often subjected to challenging operating conditions.

4. Typical application scenarios

Industrial machinery vibration monitoring: In manufacturing plants, power generation facilities, and other industrial setups with complex machinery, the 128229 – 01 is extensively used for vibration monitoring. For example, in a large – scale power plant’s steam turbine, the module can be connected to proximity and seismic transducers installed on the turbine’s shaft and casing. By continuously monitoring the vibrations of the turbine, it can detect any abnormal behavior, such as unbalanced forces or misalignment. In a manufacturing plant’s high – speed conveyor system, the 128229 – 01 can monitor the vibrations of the motors and rollers, ensuring smooth operation and preventing conveyor belt slippage or damage.

Seismic monitoring in critical infrastructure: In industries where the safety of critical infrastructure is of utmost importance, such as petrochemical plants and nuclear power stations, the 128229 – 01 can be used for seismic monitoring. It can detect even the slightest seismic activity that could potentially affect the integrity of the equipment. For instance, in a petrochemical plant, if there is a minor earthquake or ground vibration, the module can quickly detect the changes in the position and vibration of storage tanks, pipelines, and other critical components. This early detection allows plant operators to take preventive measures, such as shutting down non – essential operations and ensuring the safety of personnel.

Condition assessment of rotating equipment: For rotating machinery like pumps, compressors, and motors, the 128229 – 01 is an essential tool for condition assessment. It can measure parameters such as shaft eccentricity and thrust position, which are key indicators of the health of the rotating parts. In a compressor, the module can monitor the position of the piston and the alignment of the crankshaft. By detecting any deviations from normal operating conditions, maintenance can be scheduled at the appropriate time, reducing the risk of catastrophic failures and extending the lifespan of the equipment.

BENTLY 128229-01

5. Related model recommendations

BENTLY 3500/45M: This is another module in the 3500 series. While the 128229 – 01 focuses on proximitor and seismic I/O functions, the 3500/45M may have additional features or capabilities, such as more advanced signal analysis or additional input/output options. In some industrial setups where more comprehensive data analysis is required, the 3500/45M can be used in combination with the 128229 – 01. The two modules can work together to provide a more complete picture of machinery health, with the 128229 – 01 handling the basic signal input and initial processing, and the 3500/45M performing in – depth analysis of the data.

3500/92M Communication Gateway: When the 128229 – 01 needs to communicate with other systems or networks, the 3500/92M Communication Gateway can be a valuable addition. It can enable seamless data transfer between the 128229 – 01 and other industrial control systems, such as a plant’s distributed control system (DCS) or a remote monitoring station. For example, in a large – scale industrial complex, the 3500/92M can collect the data from multiple 128229 – 01 modules installed on different pieces of equipment and transmit this data to a central control room for real – time monitoring and analysis.

133323 – 01 Vibration Transmitter (if applicable): If the output signals from the 128229 – 01 need to be converted or transmitted in a different format to be compatible with other devices in the industrial network, the 133323 – 01 Vibration Transmitter can be used. This can improve the overall connectivity and compatibility of the 128229 – 01 within the industrial monitoring system. For instance, if the receiving device requires a different voltage or current signal standard, the 133323 – 01 can convert the output of the 128229 – 01 to the required format, ensuring smooth data flow and integration.

6. Installation, commissioning and maintenance instructions

Installation preparation: Before installation, carefully review the detailed installation manual provided by BENTLY NEVADA. Ensure that the installation environment meets the module’s requirements in terms of temperature, humidity, and electromagnetic compatibility. The 128229 – 01 is designed to be installed within a relevant rack system, such as the 3500 series rack. When installing, follow the provided mounting instructions precisely, ensuring proper alignment and secure fastening. Make sure to connect the proximity and seismic transducers correctly to the appropriate input channels, and check all wiring connections for tightness and integrity.

Commissioning: After installation, power up the 128229 – 01 and check for any error indicators. Use diagnostic tools provided by BENTLY or compatible third – party tools to verify the module’s basic functionality. Test its ability to receive signals from the transducers by introducing some controlled vibrations or changes in proximity. Calibrate the module if necessary, following the calibration procedures outlined in the manual. Ensure that all communication protocols between the module and the connected data acquisition or control system are correctly configured to enable seamless data transfer. Also, program the alarm thresholds according to the normal operating parameters of the machinery being monitored.

Maintenance suggestions: Regularly inspect the 128229 – 01 for any signs of physical damage, such as cracks in the housing or loose connections. Check the data output accuracy periodically to ensure optimal performance. Clean the module’s surface and connectors with a non – abrasive cleaner to remove any dirt or oxidation that could affect the signal quality. In harsh environments, consider more frequent inspections. If the module is used in a location with high levels of dust or moisture, ensure that the protective features are maintained. In case of any issues, refer to the troubleshooting guide in the manual or contact BENTLY’s technical support team promptly. Also, periodically review and update the alarm thresholds as the machinery’s operating conditions may change over time.

7. Service and guarantee commitment

BENTLY NEVADA typically offers a warranty for the 128229 – 01, covering defects in materials and workmanship. The exact duration of the warranty can be confirmed through official BENTLY channels. Their global technical support team is available around the clock to assist customers with installation, commissioning, and troubleshooting. Customers can access a wealth of online resources, including detailed installation manuals, calibration guides, and comprehensive technical documentation, through BENTLY’s official website. In case of module failure, BENTLY stocks a sufficient range of spare parts, ensuring quick replacement and minimizing downtime for industrial operations relying on this module. They also offer training programs for customers to better understand the operation and maintenance of the 128229 – 01, enhancing the overall user experience and promoting long – term reliable use of the product.