Description

1. Product Overview

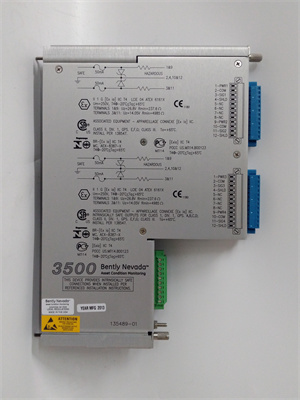

The 135489-01 is a 4-channel I/O module with built-in intrinsic safety barriers, serving as the interface between sensors and the 3500 monitoring system. It supports Proximity (Prox) and Acceleration (Accel) sensor inputs, making it ideal for measuring parameters like radial vibration, axial position, eccentricity, and differential expansion in turbines, compressors, and motors. The module’s intrinsic safety design ensures compliance with explosion-proof requirements in hazardous areas, while its compact form factor fits seamlessly into the 3500 rack system .

2. Parameter List

| Parameter Name | Parameter Value |

| Product Model | 135489-01 |

| Manufacturer | BENTLY NEVADA |

| Product Category | 4-channel I/O module with intrinsic safety barriers for 3500 series |

| Sensor Compatibility | Proximity probes, velocity sensors, acceleration sensors |

| Measurement Functions | Radial vibration, axial position, eccentricity, differential expansion, velocity |

| Input Channels | 4 (configurable for Prox/Accel) |

| Power Supply | -24 VDC (typical consumption: 7.7 W) |

| Signal Output | 0–12 VDC (analog), relay outputs (optional) |

| Barrier Type | Intrinsic safety barriers for hazardous area applications |

| Communication | Direct integration with 3500 system; supports Modbus RTU via 3500/15 module |

| Operating Temperature | -40°C to +85°C |

| Environmental Rating | IP65 (dust and water jet protection) |

| Certifications | CE, ATEX (hazardous area compliance) |

| Weight | ~0.46 kg (with barriers) |

BENTLY 135489-01

3. Technical Features and Advantages

Multi-Functional Signal Conditioning

The module processes signals from proximity probes (for shaft displacement) and acceleration sensors (for casing vibration), providing real-time data for predictive maintenance. For example, it can measure turbine shaft vibration with a sensitivity of 3.94 mV/µm (100 mV/mil) or 7.87 mV/µm (200 mV/mil), ensuring early detection of misalignment or bearing wear .

Intrinsic Safety Design

The built-in barriers isolate sensor signals, preventing sparking in explosive environments (e.g., oil refineries or chemical plants). This eliminates the need for external safety barriers, simplifying system architecture and reducing installation costs .

High Precision and Reliability

With an accuracy of ±0.33% of full scale for vibration measurements, the module ensures precise monitoring of machinery health. Its robust design includes EMI/RFI shielding and temperature compensation, maintaining performance in harsh industrial conditions .

Flexible Configuration

Each channel can be independently configured via the 3500 Configuration Software to support different sensor types and measurement ranges. For instance, in a power plant, one channel might monitor turbine shaft vibration (Prox), while another tracks compressor casing acceleration (Accel) .

Seamless System Integration

The module directly connects to the 3500 rack, enabling real-time data sharing with other modules (e.g., 3500/15 communication module for Modbus TCP/IP integration with SCADA systems). This allows operators to analyze vibration trends alongside temperature or pressure data for comprehensive equipment diagnostics .

4. Typical Application Scenarios

Power Generation

Turbine Monitoring: Installed in steam or gas turbines to measure shaft displacement and casing vibration. For example, detecting blade fouling in a steam turbine by analyzing vibration patterns .

Generator Protection: Monitoring stator winding temperature and bearing vibration to prevent catastrophic failures.

Oil & Gas

Compressor Surveillance: Detecting rotor unbalance in centrifugal compressors using proximity probes, ensuring safe operation in hazardous zones .

Pump Condition Monitoring: Using acceleration sensors to identify cavitation or bearing wear in hydrocarbon pumps.

Manufacturing

Motor Health Analysis: Monitoring vibration in high-speed motors driving conveyor belts or machining centers to schedule predictive maintenance .

Gearbox Diagnostics: Analyzing gear mesh frequencies to detect tooth damage in industrial gearboxes.

BENTLY 135489-01

5. Installation and Maintenance Guidelines

Installation:

Insert the module into a full-height slot in the 3500 rack, ensuring proper grounding.

Connect Prox/Accel sensors to the terminals, following the wiring diagram provided in the manual.

Configure channel parameters (e.g., sensor type, alarm thresholds) using the 3500 Configuration Software.

Verify signal integrity by simulating sensor inputs (e.g., applying a known vibration signal to test alarm functionality) .

Maintenance:

Routine Checks: Inspect connectors for corrosion and cable integrity monthly.

Calibration: Recalibrate sensors and the module annually using BENTLY NEVADA’s calibration tools to maintain accuracy.

Firmware Updates: Regularly update firmware via BENTLY’s official portal to access new features and bug fixes.

Troubleshooting: Use the 3500 system’s diagnostic tools to identify communication errors or sensor malfunctions .

6. Service and Support

Warranty: 12-month warranty covering defects in materials and workmanship .

Technical Support: 24/7 global support from BENTLY NEVADA’s engineering team for installation, configuration, and troubleshooting.

Documentation: Online access to user manuals, wiring diagrams, and safety guidelines via BENTLY’s official website.

Training: Customized training programs on sensor installation, module configuration, and predictive maintenance strategies.

By integrating the BENTLY 135489-01 into machinery monitoring systems, industries can achieve proactive maintenance, reduce downtime, and enhance operational safety in both standard and hazardous environments. Its rugged design, multi-functionality, and seamless compatibility with the 3500 series make it a cornerstone for critical equipment protection.