Description

1. Detailed parameter table

| Parameter name | Parameter value |

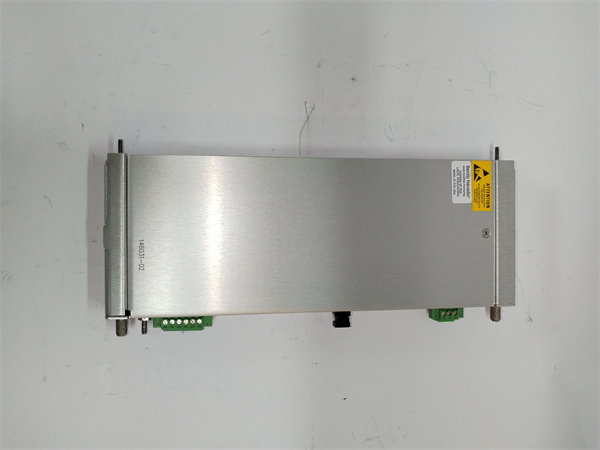

| Product model | 146031 – 02 |

| Manufacturer | BENTLY NEVADA |

| Product category | Transient Data Interface I/O Module (presumed based on related model 146031 – 01) |

| Series | N/A (specific to this module) |

| Interface type | Designed for seamless connection within industrial control systems; likely supports data communication protocols relevant to vibration monitoring and control setups |

| Operating voltage | 220 V (similar to related model 146031 – 01, subject to confirmation) |

| Output frequency | 50 kHz (akin to 146031 – 01, needs verification) |

| Environmental resistance | Built to endure harsh industrial conditions; resistant to factors like temperature fluctuations, humidity, and electromagnetic interference |

| Dimensions | N/A (awaiting official details) |

| Weight | N/A (pending official information) |

| Certifications | Expected to meet industry – standard certifications for industrial control modules, such as those related to safety and quality in industrial environments |

BENTLY 146031-02

2. Product introduction

The BENTLY NEVADA 146031 – 02 is a sophisticated industrial control module, likely a transient data interface I/O module, given its relation to the 146031 – 01 model. Engineered with precision, it plays a pivotal role in industrial settings where accurate data monitoring and control are non – negotiable.

This module is designed to integrate seamlessly into existing industrial control systems, facilitating the transfer and processing of data related to various industrial processes. It serves as a crucial link in ensuring that operations run smoothly and efficiently, especially in applications where real – time data analysis and response are essential for maintaining optimal performance and preventing equipment failures.

3. Core advantages and technical highlights

Robust construction for harsh environments: Just like its related model 146031 – 01, the 146031 – 02 is crafted to endure the rigors of harsh industrial environments. It can withstand extreme temperature variations, high humidity levels, and intense electromagnetic interference. This resilience ensures consistent performance over extended periods, minimizing the risk of disruptions due to environmental factors.

Advanced signal processing capabilities: Equipped with state – of – the – art signal processing technology, the 146031 – 02 is capable of real – time data collection and analysis. It can swiftly and accurately process incoming data, providing valuable insights for predictive maintenance and condition – based monitoring systems. By detecting early signs of equipment malfunctions, it enables proactive measures to be taken, reducing unplanned downtime and maintenance costs.

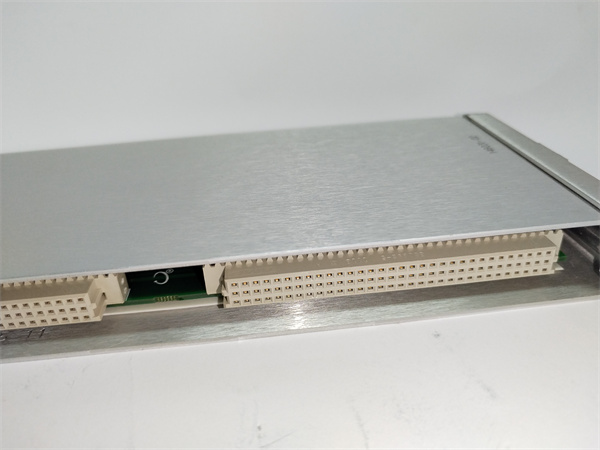

Durable materials for long – term reliability: The module features a robust construction using durable materials that resist corrosion and wear. This not only contributes to its long service life but also ensures minimal downtime. In industrial settings where continuous operation is crucial, the 146031 – 02’s reliability is a key advantage, allowing for uninterrupted data transfer and control.

4. Typical application scenarios

Industrial machinery vibration monitoring: In manufacturing plants, power generation facilities, and other industrial setups with complex machinery, the 146031 – 02 can be integrated into vibration monitoring systems. It can collect and process data from vibration sensors, such as the BENTLY NEVADA 330500 – 00 – 00 or 330709 – 000 – 050 – 10 – 02 – 00. By analyzing the vibration data in real – time, it can help detect issues like bearing wear, misalignment, or imbalance in rotating machinery, enabling timely maintenance to prevent catastrophic failures.

Process control in chemical plants: In chemical plants, where precise control of processes is essential for safety and product quality, the 146031 – 02 can be used to interface with various sensors and control valves. It can collect data on parameters such as temperature, pressure, and flow rate, and transmit processed signals to control systems. This ensures that chemical reactions occur within the desired ranges, optimizing production efficiency and minimizing the risk of accidents.

Automated production lines: In modern automated production lines, the 146031 – 02 can play a vital role in coordinating the operation of different components. It can communicate with sensors that detect the position and movement of products on the line, as well as with actuators that perform tasks like sorting, packaging, and assembly. By processing the data from these sensors and sending appropriate control signals, it helps ensure the smooth flow of production and reduces errors.

5. Related model recommendations

BENTLY 146031 – 01: As a closely related model, the 146031 – 01 shares many similarities with the 146031 – 02. It can be used in parallel or as a backup in industrial control setups, providing redundancy and enhanced reliability. The two models may have slight differences in features or performance, allowing users to choose the most suitable one for their specific applications.

3500/42M Vibration Monitor: When combined with the 146031 – 02 in a BENTLY 3500 system, the 3500/42M Vibration Monitor can enhance the capabilities of the overall vibration monitoring solution. It can provide in – depth frequency analysis and real – time alarm triggers based on the data processed by the 146031 – 02, helping operators quickly identify and respond to abnormal vibration conditions in critical machinery.

133323 – 01 Vibration Transmitter: If the 146031 – 02 needs to interface with devices that require a different signal format, the 133323 – 01 Vibration Transmitter can be used to convert the output of the module. This can improve the compatibility of the 146031 – 02 with various data acquisition or control devices in an industrial network.

BENTLY 146031-02

6. Installation, commissioning and maintenance instructions

Installation preparation: Before installation, carefully review the installation manual provided by BENTLY NEVADA. Ensure that the installation environment meets the module’s requirements in terms of temperature, humidity, and electromagnetic compatibility. Clean the installation area and make sure it is free of dust, debris, and corrosive substances. When connecting the module to other components in the system, follow the wiring diagrams precisely, ensuring proper grounding to prevent electrical interference.

Commissioning: After installation, power up the 146031 – 02 and check for any error indicators. Use diagnostic tools provided by BENTLY or compatible third – party tools to verify the module’s functionality. Test its data transfer capabilities by sending and receiving sample data. Calibrate the module if necessary, following the calibration procedures outlined in the manual. Ensure that all communication protocols are correctly configured to enable seamless integration with other components in the industrial control system.

Maintenance suggestions: Regularly inspect the 146031 – 02 for any signs of physical damage, such as cracks in the housing or loose connections. Check the data transfer rates and accuracy periodically to ensure optimal performance. Clean the module’s connectors and ports with a non – abrasive cleaner to remove any dirt or oxidation that could affect the electrical connection. If the module is used in a particularly harsh environment, consider more frequent inspections and maintenance. In case of any issues, refer to the troubleshooting guide in the manual or contact BENTLY’s technical support team.

7. Service and guarantee commitment

BENTLY NEVADA typically offers a warranty for the 146031 – 02, covering defects in materials and workmanship. The exact duration of the warranty can be confirmed through official channels. Their global technical support team is available to assist customers with installation, commissioning, and troubleshooting. Customers can access online resources, including installation manuals, calibration guides, and technical documentation, through BENTLY’s official website. In case of module failure, BENTLY stocks a range of spare parts, ensuring quick replacement and minimizing downtime for industrial operations relying on this module. They also offer training programs for customers to better understand and maintain the module, enhancing the overall user experience.