Description

1. Product overview

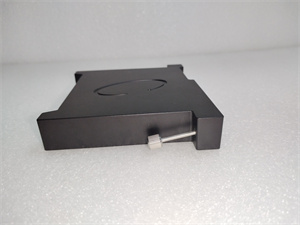

The BENTLY 170180 – 01 – 05 is a sophisticated field monitor transducer I/O module, playing a pivotal role in BENTLY’s machinery condition monitoring ecosystem. Engineered to interface seamlessly with proximity sensors and accelerometers, it serves as a crucial link in collecting, processing, and relaying vital data about the operational state of industrial machinery. By integrating with a BENTLY field monitor, this module enables real – time assessment of parameters such as vibration levels, shaft displacement, and acceleration, which are fundamental for ensuring the reliable and efficient operation of rotating equipment.

2. Parameter list

| Parameter name | Parameter value |

| Product model | 170180 – 01 – 05 |

| Manufacturer | BENTLY NEVADA |

| Product category | Field monitor transducer I/O module |

| Input voltage | Operates within a range of 18 – 32 VDC, allowing for compatibility with various power sources in industrial setups. This wide input voltage range ensures stable operation even in environments where power supply fluctuations might occur. |

| Input current | Draws 20 mA, indicating its relatively low power consumption while still maintaining high – performance data acquisition capabilities. |

| Output voltage | Capable of providing an output voltage in the range of 0 – 10 VDC, which is suitable for transmitting processed sensor data to control systems or data loggers. This voltage output can be easily interpreted by downstream equipment for further analysis. |

| Output current | The output current is set at 20 mA, ensuring reliable signal transmission over different types of connections. |

| Frequency response | Covers a broad frequency range from 10 Hz to 10 kHz. This wide frequency response enables the module to accurately capture and process signals from a variety of industrial machinery, whether it’s low – speed rotating equipment or high – speed turbines. |

| Accuracy | Achieves an accuracy of ±1% full scale, providing highly precise measurements of machinery parameters. This level of accuracy is essential for detecting even the slightest deviations in equipment performance, which could be early indicators of potential failures. |

| Temperature range | Designed to function in extreme temperature conditions, with an operating temperature range spanning from – 40 °C to + 85 °C. This makes it suitable for use in a wide array of industrial applications, from cold storage facilities to high – temperature industrial furnaces. |

| Humidity range | Can operate in humidity levels ranging from 0% to 100% relative humidity (RH). Its resistance to high humidity environments ensures reliable performance in industries such as food and beverage processing, where moisture is often present. |

| Vibration resistance | Can withstand vibrations of up to 2 g peak acceleration in the frequency range of 10 to 500 Hz. This makes it robust enough to be installed directly on vibrating machinery without being affected by the mechanical vibrations, ensuring continuous and accurate data collection. |

| Shock resistance | Capable of enduring shocks of 30 g for 11 ms. This high shock resistance protects the module from damage during sudden impacts, which might occur during equipment startup, shutdown, or in case of mechanical failures. |

| EMC compliance | Complies with EMC standards such as EN 50081 – 2 and EN 50082 – 2, ensuring that it can operate in electromagnetic – rich industrial environments without interference issues. This compliance is crucial for maintaining the integrity of the sensor data being processed and transmitted. |

| Number of channels | Features two channels, allowing it to interface with up to two transducers simultaneously. This enables the monitoring of multiple parameters or multiple points on a single piece of equipment. |

| Mounting | Occupies one slot in a field monitor terminal base, providing a convenient and standardized way of integrating it into existing BENTLY field monitoring systems. |

| Weight | Weighs approximately 270 grams, making it a lightweight yet highly functional component. The lightweight design facilitates easy installation and reduces the overall load on the monitoring system infrastructure. |

| Certification | Holds the lbl # 143542 – 01 rev a ex na IIC T4 @ Ta = 70 °C certification, making it suitable for use in Class 1, Division 2 groups A, B, C & D environments. This certification ensures safety and compliance in hazardous industrial areas. |

BENTLY 170180-01-05

3. Product features and technical highlights

High – precision data acquisition: The 170180 – 01 – 05 is engineered to acquire data with remarkable precision. Its ±1% full – scale accuracy allows it to detect even the most minute changes in machinery parameters. For example, in a gas turbine power plant, it can accurately measure the slightest vibrations in the turbine blades. These precise measurements are crucial for early detection of blade fatigue or misalignment, enabling preventive maintenance and avoiding costly breakdowns.

Robust environmental adaptability: With its wide temperature, humidity, vibration, and shock resistance capabilities, this module can thrive in some of the harshest industrial environments. In an offshore oil rig, it can endure the extreme temperatures, high humidity, and constant vibrations associated with the operation of drilling equipment. The ability to function reliably in such conditions ensures continuous monitoring of critical machinery, regardless of the external environment.

Hot – swappable design: One of the notable features of the 170180 – 01 – 05 is its hot – swappable design. This means that it can be replaced or inserted into the field monitor terminal base while the system is still operational. In a large manufacturing plant where downtime is costly, this feature allows for quick replacement of a faulty module without having to shut down the entire monitoring system. This significantly reduces maintenance time and increases the overall availability of the machinery condition monitoring system.

Built – in diagnostics: The module comes equipped with built – in diagnostic capabilities. It can continuously assess its own integrity as well as that of the connected transducers. If any issues are detected, such as a malfunctioning transducer or a problem with the module itself, it can generate an alarm signal. In a chemical processing plant, this built – in diagnostic feature can quickly alert operators to a problem with a vibration sensor connected to the module, allowing for prompt corrective action to be taken.

Compatibility and ease of integration: It is fully compatible with all BENTLY field monitors, ensuring seamless integration into existing monitoring systems. Its two – wire loop I/O design simplifies the wiring process, reducing installation complexity. In an industrial automation setup, this compatibility and ease of integration mean that it can be easily added to an existing BENTLY – based machinery health monitoring network, allowing for the expansion of monitoring capabilities without major system overhauls.

4. Typical application scenarios

Power generation industry: In power plants, whether they are coal – fired, gas – fired, or hydro – electric, the 170180 – 01 – 05 is used to monitor the health of turbines, generators, and pumps. By connecting proximity sensors and accelerometers to the module, it can measure shaft vibration, displacement, and acceleration. For instance, in a steam turbine, it can detect any abnormal vibrations that might be caused by bearing wear or blade imbalance. This data is then used to predict equipment failures and schedule maintenance, ensuring the continuous and efficient operation of the power plant.

Industrial manufacturing: In manufacturing plants, high – speed motors, conveyor belts, and robotic arms are critical components. The 170180 – 01 – 05 is used to monitor the performance of these devices. In an automotive manufacturing plant, it can be used to monitor the vibration of robotic arms during the assembly process. If the vibration levels exceed the set thresholds, it can indicate a problem with the arm’s joints or motors, allowing for timely maintenance to prevent production disruptions.

Oil and gas industry: In the oil and gas sector, pumps, compressors, and drilling equipment are constantly under stress. The 170180 – 01 – 05 helps in monitoring the condition of these assets. For example, on an offshore drilling rig, it can connect to sensors on a mud pump. By measuring the pump’s vibration and acceleration, it can detect signs of wear in the pump’s impellers or bearings. This early detection of potential problems helps in reducing downtime and ensuring the safe and efficient operation of the drilling process.

BENTLY 170180-01-05

5. Installation and maintenance guidelines

Installation: Prior to installation, carefully study the detailed installation manual provided by BENTLY NEVADA. Ensure that the installation area is clean and free from any debris that could potentially damage the module. When installing, align the module correctly with the slot in the field monitor terminal base and gently insert it until it clicks into place. Check all the electrical connections for tightness to prevent loose connections that could lead to signal interference or power issues. Route the cables connecting the module to the sensors and other components in a way that avoids contact with moving parts, hot surfaces, or areas with high electromagnetic fields.

Maintenance: Regularly inspect the 170180 – 01 – 05 for any signs of physical damage, such as cracks in the casing or loose connectors. Clean the module surface periodically to remove dust and debris, especially in dusty industrial environments. Use the built – in diagnostic features to check the integrity of the module and the connected transducers. If any alarms are triggered, refer to the troubleshooting guide in the manual. In case of a malfunction, contact BENTLY’s technical support team for assistance. Periodically, check for any software or firmware updates from BENTLY to ensure that the module is operating at its optimal performance level.

6. Service and support

BENTLY NEVADA offers a comprehensive service and support package for the 170180 – 01 – 05. The product typically comes with a 12 – month warranty covering defects in materials and workmanship. Their global technical support team is available around the clock to assist customers with installation, commissioning, and troubleshooting. Customers can access a wealth of online resources, including detailed installation manuals, wiring diagrams, and technical documentation, on BENTLY’s official website. In the event of a product failure, BENTLY maintains a sufficient inventory of replacement modules, ensuring quick turnaround times and minimizing downtime for industrial operations that rely on this critical component. They also offer training programs for customers to help them better understand the operation, installation, and maintenance of the 170180 – 01 – 05, enhancing the overall user experience and promoting long – term reliable use of the product.