Description

1. Detailed parameter table

| Parameter name | Parameter value |

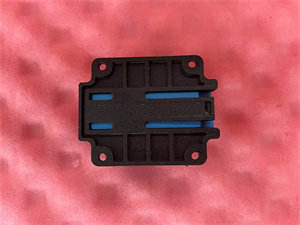

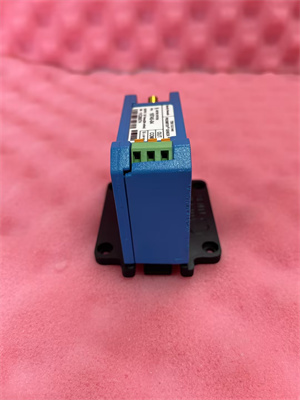

| Product model | 18745 – 04 |

| Manufacturer | BENTLY NEVADA |

| Product category | Proximitor Sensor |

| Series | 7200 |

| Probe diameter | 5mm |

| Part voltage rating | -18 to -24 VDC |

| Cable length | 9m |

| Dimensions (HxWxD) | Approx: 8.13 cm x 6.12 cm x 6.35 cm |

| Shipping weight | 2 kg |

| Frequency response | 0 Hz (DC) to 10 kHz |

| Measuring range | 80 mils (2 mm) of linear measuring range |

| Compatibility | Compatible with 3300 and 9000 monitoring systems, and all 5 & 8 mm 7200 probes |

| Measurement technique | Inductive proximity measurement |

BENTLY 18745-04

2. Product introduction

The BENTLY NEVADA 18745 – 04 is a high – precision proximitor sensor belonging to the 7200 series. Engineered for industrial applications, this sensor is designed to measure the distance between the probe tip and the target object accurately. It operates on the principle of inductive proximity measurement, where it generates a magnetic field and detects changes in that field as the target object approaches or moves away.

This sensor is a crucial component in a proximity transducer system, which also includes a probe with an integral coaxial cable and an extension cable. The 18745 – 04 converts the gap between the probe and the target into a proportional voltage output, making it suitable for monitoring both static and dynamic distances. Its applications span a wide range of industries, with a primary focus on rotating and reciprocating machinery, where accurate displacement measurements are essential for maintaining optimal performance and safety.

3. Core advantages and technical highlights

Wide frequency response: With a frequency response ranging from 0 Hz (DC) to 10 kHz, the 18745 – 04 can effectively capture both slow – moving (static) and high – speed (dynamic) changes in the position of the target object. This makes it suitable for applications where machinery operates at varying speeds, such as in a power plant where turbines may ramp up or down during startup and shutdown procedures.

Non – contacting measurement: The inductive proximity measurement technique employed by the 18745 – 04 eliminates the need for physical contact between the sensor and the target. This not only reduces wear and tear on the sensor and the machinery but also allows for continuous monitoring without interfering with the normal operation of the equipment. In a chemical plant, for example, the non – contacting nature of the sensor ensures that it can operate in harsh environments without being affected by corrosive substances that could damage contact – based sensors.

API 670 compatibility: The sensor’s system offers an 80 – mil (2 mm) linear measuring range and is compatible with API 670 requirements. API 670 is a widely recognized standard in the oil, gas, and petrochemical industries for machinery protection systems. This compatibility ensures that the 18745 – 04 can be seamlessly integrated into existing monitoring and protection systems in these industries, providing reliable data for machinery health assessment.

Compatibility with multiple monitoring systems: The 18745 – 04 is compatible with both 3300 and 9000 monitoring systems. This flexibility allows for easy integration into different industrial setups, whether they are using older or more advanced monitoring infrastructure. It also simplifies the process of upgrading or replacing existing sensors, as it can work with a variety of systems without requiring a complete overhaul of the monitoring system.

4. Typical application scenarios

Turbine shaft monitoring: In a power generation facility, gas or steam turbines are critical components. The 18745 – 04 can be used to monitor the shaft position and vibration of the turbine. By measuring the displacement of the shaft relative to its housing, it can detect early signs of misalignment, which could lead to increased vibration and potential damage to the turbine blades. For example, if the shaft displacement exceeds a certain threshold, it could indicate a problem with the bearing system, and maintenance can be scheduled before a major failure occurs.

Compressor vibration analysis: In an oil refinery, compressors are used to increase the pressure of gases. The 18745 – 04 can monitor the vibration of the compressor shaft. Unusual vibration patterns can be an indication of issues such as worn bearings, imbalanced rotors, or misaligned components. By continuously monitoring the vibration using this sensor, plant operators can take proactive measures to prevent compressor failures, which could disrupt the production process and result in significant downtime and financial losses.

Centrifuge operation control: In a wastewater treatment plant, centrifuges are used to separate solids from liquids. The 18745 – 04 can be installed to monitor the position and vibration of the centrifuge’s rotating drum. Any deviation from normal operating parameters, such as excessive vibration due to uneven distribution of solids in the drum, can be detected. This allows operators to adjust the centrifuge’s operation or perform maintenance as needed to ensure efficient and reliable separation of solids from wastewater.

BENTLY 18745-04

5. Related model recommendations

7200 series probes: These probes are specifically designed to work with the 18745 – 04 proximitor sensor. They come in various diameters (5mm and 8mm) and lengths, allowing for customization based on the specific application requirements. For example, in a compact machinery setup, a shorter 5mm probe may be more suitable, while in a larger industrial equipment, an 8mm probe with a longer reach might be necessary.

Extension cables: When the standard 9m cable length of the 18745 – 04 is not sufficient, extension cables can be used. These cables are designed to maintain the integrity of the signal transmission over longer distances, ensuring accurate measurement data. They are available in different lengths and are compatible with the 7200 series proximity transducer systems.

3300 monitoring system: As the 18745 – 04 is compatible with the 3300 monitoring system, this combination provides a comprehensive solution for machinery condition monitoring. The 3300 system offers advanced features such as data analysis, trending, and alarm capabilities, which can be used to further analyze the data collected by the 18745 – 04 sensor and make more informed decisions about machinery maintenance.

9000 monitoring system: Similar to the 3300 system, the 9000 monitoring system can be paired with the 18745 – 04. The 9000 system may offer additional features or different levels of functionality, depending on the specific needs of the industrial application. It can also be used to integrate the sensor data with other monitoring parameters in a more complex industrial setup.

6. Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the area where the sensor will be mounted is clean and free from any debris. Check the compatibility of the 18745 – 04 with the selected probe and extension cable (if required). Mount the sensor securely using appropriate mounting brackets, ensuring that it is aligned correctly with the target object. Route the cable away from high – voltage lines and other sources of electromagnetic interference to minimize signal distortion.

Commissioning: Once installed, power on the sensor and check for any error indicators. Use a calibration tool to verify the accuracy of the sensor’s output. Adjust the calibration if necessary to ensure that the voltage output is proportional to the distance between the probe tip and the target object. Test the sensor’s response to changes in the target object’s position by gently moving the object within the sensor’s measuring range and observing the corresponding changes in the output signal.

Maintenance suggestions: Regularly inspect the sensor for any signs of physical damage, such as cracks in the housing or loose cable connections. Check the cable for any signs of wear or damage, and replace it if necessary. Periodically (e.g., annually) perform a calibration check using a certified calibration device to ensure that the sensor is still providing accurate measurements. If the sensor is used in a harsh environment, such as one with high humidity or extreme temperatures, consider more frequent inspections and calibration checks to maintain its performance.

7. Service and guarantee commitment

BENTLY NEVADA typically offers a 12 – month warranty for the 18745 – 04, covering defects in materials and workmanship. Their technical support team is available to provide assistance for installation, calibration, and troubleshooting. Customers can access online resources, including installation manuals and calibration guides, through BENTLY’s official website. In case of sensor failure, BENTLY stocks a range of spare parts, ensuring quick replacement and minimizing downtime for industrial operations relying on this sensor. For critical applications, on – site support may be available upon request to ensure proper installation and calibration.