Description

1. Detailed parameter table

| Parameter name | Parameter value |

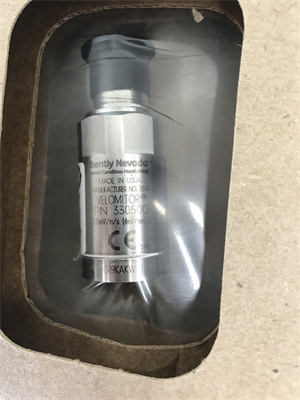

| Product model | 330500 – 00 – 00 |

| Manufacturer | BENTLY NEVADA |

| Product category | Velomitor Piezo – velocity Sensor |

| Series | N/A (specific to this piezo – velocity sensor model) |

| Sensor type | Piezoelectric with embedded integrated electronics |

| Measurement range | Suitable for typical industrial vibration levels; measures absolute (relative to free space) bearing housing, casing, or structural vibration |

| Frequency range | 10 Hz to 1 kHz |

| Sensitivity | 78.7 mV/g ± 5% or 78.7 mV/mm/s (depending on measurement unit context) |

| Output signal | 4 – 20 mA |

| Operating voltage | 24 VDC |

| Operating temperature | – 40 °C to + 125 °CSome sources also mention – 55 °C to + 121 °C |

| Storage temperature | N/A (not widely specified, but likely within a similar range considering operating conditions) |

| Housing material | 316L stainless steel |

| Connector | 2 – pin MIL – C – 5015 hermetically sealed, 316L stainless steel shell |

| Mounting | Mounting torque: 46 kg·cm (40 in – lb) max.Mounting options: Flange or studCan be mounted vertically, horizontally, or at any angle |

| Dimensions | Height: 63.2 mm (2.49 in)Diameter: 25.3 mm (0.995 in) |

| Weight | N/A (shipping weight around 2 kg including packaging) |

| Protection rating | NEMA 4X/IP67 (protection against dust, water, and other contaminants)Case is hermetically – sealed |

| Certifications | CE, UL, ATEX, IECEx (meets stringent quality and safety requirements) |

BENTLY 330500-00-00

2. Product introduction

The BENTLY NEVADA 330500 – 00 – 00 is a high – performance Velomitor Piezo – velocity Sensor, engineered to provide accurate and reliable vibration monitoring in industrial applications. Unlike traditional moving – coil velocity transducers, this sensor utilizes piezoelectric technology with embedded integrated electronics in a solid – state design.

This sensor is designed to measure the absolute vibration of bearing housings, casings, or structural components relative to free space. By precisely converting mechanical vibrations into an electrical signal, it plays a crucial role in condition monitoring systems. It enables the early detection of potential issues in rotating machinery, such as turbines, compressors, and pumps, helping industries avoid costly equipment failures and unscheduled downtime.

3. Core advantages and technical highlights

Solid – state durability: With no moving parts, the 330500 – 00 – 00 is highly resistant to mechanical degradation and wear. This makes it suitable for long – term, continuous operation in industrial environments where vibrations and mechanical stress are common. Its solid – state design also allows for flexible mounting orientations, whether vertical, horizontal, or at any other angle, without affecting its performance.

Wide temperature tolerance: Operating within a temperature range of – 40 °C to + 125 °C (and in some cases – 55 °C to + 121 °C), the sensor can withstand extreme thermal conditions. This is particularly useful in industries like power generation, where equipment may operate in high – temperature environments, or in cold – climate regions where machinery is exposed to sub – zero temperatures.

High – sensitivity measurement: Boasting a sensitivity of 78.7 mV/g ± 5% (or 78.7 mV/mm/s), the sensor can detect even subtle vibrations. This high sensitivity is essential for accurately monitoring the health of industrial machinery. It can pick up early signs of bearing wear, misalignment, or imbalance, which may manifest as small changes in vibration patterns.

Reliable output signal: The 4 – 20 mA output signal is a standard in industrial control systems, ensuring seamless integration with existing infrastructure. This allows for easy communication with other components in a condition monitoring network, such as data acquisition systems, PLCs (Programmable Logic Controllers), or DCSs (Distributed Control Systems).

Robust construction: Housed in a 316L stainless steel case with a hermetically sealed 2 – pin MIL – C – 5015 connector, the sensor is well – protected against environmental factors. The NEMA 4X/IP67 rating means it can resist dust, water, and other contaminants, making it suitable for use in harsh industrial settings, including those with high humidity, dust, or water splashing.

4. Typical application scenarios

Power plant machinery monitoring: In a power plant, turbines and generators are critical components. The 330500 – 00 – 00 can be installed on the bearing housings of these machines to monitor vibration levels. By continuously measuring vibrations in the frequency range of 10 Hz to 1 kHz, it can detect abnormal patterns that may indicate issues such as turbine blade damage, generator rotor imbalance, or misalignment in the drive train. Early detection allows for timely maintenance, ensuring stable power generation and preventing major equipment failures.

Petrochemical and refinery applications: In petrochemical plants and refineries, compressors and pumps are used extensively. The sensor can be mounted on the casings of these devices to monitor their vibration. For example, in a reciprocating compressor, changes in vibration can signal problems with the pistons, valves, or connecting rods. In a centrifugal pump, increased vibration may indicate worn impellers or seal failures. The sensor’s ability to operate in harsh chemical environments, thanks to its stainless – steel construction and protective rating, makes it an ideal choice for such applications.

Manufacturing equipment surveillance: In manufacturing facilities, various types of machinery, such as large – scale motors driving conveyor belts or high – speed spindles in machining centers, can be monitored using the 330500 – 00 – 00. By detecting vibrations in these machines, manufacturers can prevent production disruptions. For instance, if a motor driving a conveyor belt starts to vibrate abnormally, it could cause products to be misaligned or dropped. The sensor helps in identifying such issues before they lead to costly production stoppages.

BENTLY 330500-00-00

5. Related model recommendations

BENTLY NEVADA 330709 – 000 – 050 – 10 – 02 – 00 Accelerometer Sensor: While the 330500 – 00 – 00 is a piezo – velocity sensor, the 330709 – 000 – 050 – 10 – 02 – 00 is an accelerometer. Combining both sensors in a condition monitoring system can provide a more comprehensive view of machinery health. The accelerometer can capture high – frequency vibrations and shocks, while the piezo – velocity sensor focuses on lower – frequency, more continuous vibrations.

133323 – 01 Vibration Transmitter: This vibration transmitter can be used to convert the output of the 330500 – 00 – 00 (if needed) to a format more suitable for specific control systems. It can enhance the compatibility of the sensor with different types of data acquisition or control devices in an industrial network.

3500/42M Vibration Monitor: When integrated with the 330500 – 00 – 00 in BENTLY’s 3500 system, the 3500/42M Vibration Monitor can provide real – time alarm triggers and in – depth frequency analysis. This helps in quickly identifying and responding to any abnormal vibration conditions in critical machinery.

6. Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the mounting surface is clean, flat, and free of any debris or corrosion. If using a flange or stud for mounting, torque the connection to the specified 46 kg·cm (40 in – lb) maximum. Route the cable (with a maximum length of 305m or 1000 ft in some configurations) away from high – voltage lines and other sources of electromagnetic interference. For hazardous areas, verify compliance with relevant certifications such as ATEX or IECEx.

Commissioning: Once installed, power up the sensor and check for any signs of malfunction. Use a calibration device to verify the accuracy of the sensor’s output. Adjust the calibration if necessary to ensure that the sensor is providing accurate vibration readings. Test the sensor’s response to known vibration levels by using a vibration generator or by observing the vibration of a known – good machine.

Maintenance suggestions: Regularly inspect the sensor for any signs of physical damage, such as cracks in the housing or loose cable connections. Check the calibration of the sensor annually (or more frequently depending on the application) using a certified calibration tool. Clean the sensor housing with a non – abrasive cleaner, such as isopropyl alcohol, to remove any dust or contaminants. If the sensor is used in a high – temperature or high – humidity environment, consider more frequent inspections to ensure its continued reliable operation.

7. Service and guarantee commitment

BENTLY NEVADA typically offers a 1 – year warranty for the 330500 – 00 – 00, covering defects in materials and workmanship. Their global technical support team is available to assist with installation, calibration, and troubleshooting. Customers can access online resources, including installation manuals, calibration guides, and technical documentation, through BENTLY’s official website. In case of sensor failure, BENTLY stocks a range of spare parts, ensuring quick replacement and minimizing downtime for industrial operations relying on this sensor.