Description

1. Detailed parameter table

| Parameter name | Parameter value |

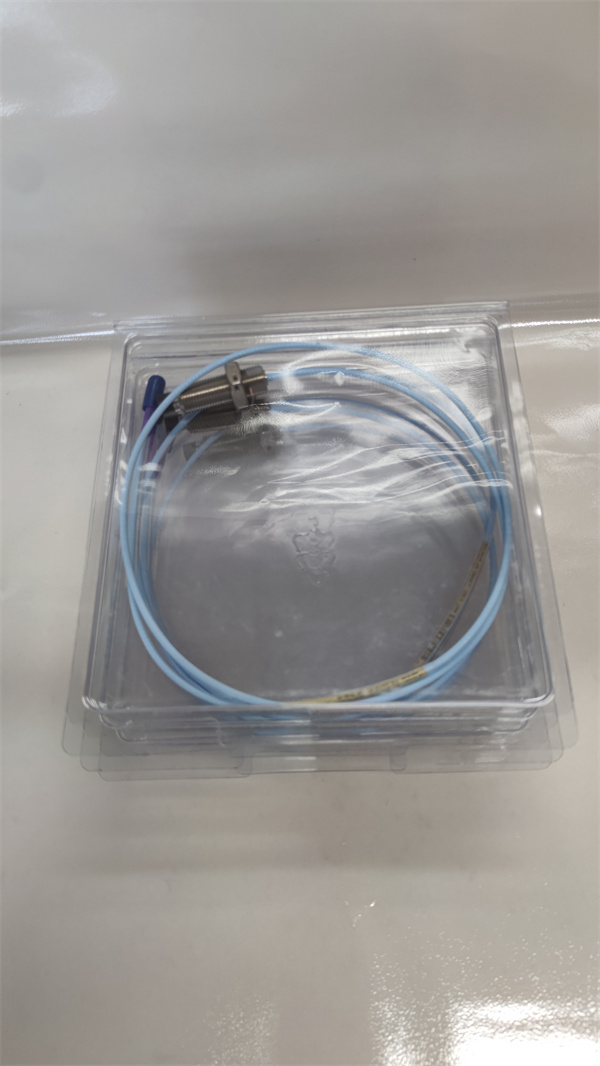

| Product model | 330709-000-050-10-02-00 |

| Manufacturer | BENTLY NEVADA |

| Product category | Accelerometer Sensor |

| Series | 3300 |

| Sensor type | Piezoelectric shear-type accelerometer |

| Measurement range | ±50 g (peak) |

| Frequency response | 0.5 Hz to 10,000 Hz |

| Sensitivity | 100 mV/g ±5% |

| Output type | Differential voltage |

| Operating temperature | -55°C to +121°C (-67°F to +250°F) |

| Storage temperature | -55°C to +163°C (-67°F to +325°F) |

| Housing material | Hermetically sealed stainless steel (316L) |

| Cable length | 10 meters (integral shielded twisted pair) |

| Weight | 155 grams (without cable) |

| Protection rating | IP68 (submersible up to 100 meters) |

| Mounting | 1/4-28 UNF threaded stud |

| Certifications | ATEX, IECEx, UL, CSA, RoHS |

BENTLY 330709-000-050-10-02-00

2. Product introduction

The BENTLY NEVADA 330709-000-050-10-02-00 is a high-performance piezoelectric accelerometer, part of the 3300 series, designed for precise measurement of vibration in industrial machinery. This shear-type sensor converts mechanical acceleration (vibration) into an electrical signal, making it ideal for monitoring dynamic forces in rotating and reciprocating equipment.

As a critical component in condition monitoring systems, the 330709-000-050-10-02-00 excels in capturing low-frequency vibrations (down to 0.5 Hz) and high-impact shocks (up to ±50 g). Its hermetic stainless steel housing and IP68 rating ensure reliability in extreme environments—from subsea pipelines to high-temperature turbine enclosures. By delivering accurate vibration data, it enables early detection of bearing wear, imbalance, or misalignment in machinery such as pumps, motors, and compressors, helping industries minimize downtime and maintenance costs.

3. Core advantages and technical highlights

Broad measurement range: With a ±50 g range, the 330709-000-050-10-02-00 handles both routine vibration and sudden shocks. In mining equipment, where crushers experience intermittent high-impact vibrations, it reliably captures both steady-state operation and transient events, ensuring comprehensive condition monitoring.

Extended temperature resilience: Operating from -55°C to +121°C, it outperforms standard accelerometers in extreme thermal environments. In gas turbine exhaust sections, where temperatures exceed 100°C, the sensor maintains stable sensitivity, unlike sensors with polymer components that degrade under heat.

Hermetic durability: The 316L stainless steel housing is hermetically sealed, preventing moisture or debris ingress even at 100-meter depths. This makes it suitable for offshore applications, such as monitoring subsea pumps or shipboard machinery exposed to saltwater spray.

Low-frequency precision: Its 0.5 Hz frequency response captures slow vibrations critical for detecting resonance in large structures, like boiler feedwater pumps. This capability is vital in power plants, where low-frequency oscillations can indicate foundation loosening or impeller cavitation.

4. Typical application scenarios

Turbine vibration monitoring: In combined-cycle power plants, the 330709-000-050-10-02-00 is mounted on gas turbine casings to measure vibration across startup, operation, and shutdown cycles. By tracking frequencies between 1 Hz and 5 kHz, it identifies blade pass harmonics or bearing defects. A sudden spike at 2x rotational speed may signal misalignment, prompting maintenance before turbine damage occurs.

Chemical pump diagnostics: In petrochemical facilities, centrifugal pumps handling corrosive fluids rely on the 330709-000-050-10-02-00 for vibration analysis. The sensor’s stainless steel housing resists chemical exposure, while its 10-meter cable allows remote mounting away from hazardous areas. Data from the sensor helps detect worn impellers (via increased vibration at 1x speed) or seal failures (indicated by erratic high-frequency spikes).

Marine engine health: On offshore drilling rigs, the sensor monitors diesel engine vibration. Its IP68 rating withstands deck washdowns and saltwater immersion, while its -55°C low-temperature tolerance ensures reliability in Arctic operations. By analyzing vibration patterns, engineers predict fuel injector wear or crankshaft imbalance, preventing engine failures during critical drilling operations.

BENTLY 330709-000-050-10-02-00

5. Related model recommendations

330709-000-025-10-02-00: A 25 g range variant of the 330709-000-050-10-02-00, ideal for low-vibration applications like precision motor monitoring.

133323-01: A vibration transmitter that converts the 330709-000-050-10-02-00’s differential output to a 4-20 mA signal, enabling integration with PLCs or DCS systems.

136188-03: A 50-meter extension cable compatible with the 330709-000-050-10-02-00, extending sensor reach in large industrial facilities.

3500/42M Vibration Monitor: Integrates with the 330709-000-050-10-02-00 in BENTLY’s 3500 system, providing real-time alarm triggers and frequency analysis for critical machinery.

330180-51-00: A proximitor sensor that, paired with the 330709-000-050-10-02-00, offers a complete condition monitoring solution—tracking both vibration (accelerometer) and shaft position (proximitor).

6. Installation, commissioning and maintenance instructions

Installation preparation: Mount the 330709-000-050-10-02-00 using a 1/4-28 UNF threaded stud, torqued to 15 Nm (11 ft-lbs) for optimal coupling. Ensure the mounting surface is flat, clean, and free of paint or corrosion—use a grit blast finish (Ra 3.2 μm) for best results. Route the integral cable away from high-voltage lines and secure with cable ties to avoid movement-induced noise. For hazardous areas, verify ATEX/IECEx compliance with the installation zone.

Maintenance suggestions: Inspect the 330709-000-050-10-02-00 quarterly for cable damage or loose mounting—replace the sensor if the cable jacket is cut or the stud is stripped. Calibrate annually using a shaker table: apply 10 g at 160 Hz and confirm output is 1.0 V ±50 mV. Avoid exposing the sensor to temperatures exceeding +121°C during operation; use a heat sink for prolonged high-temperature use. Clean the housing with isopropyl alcohol—never use abrasive cleaners that damage the stainless steel surface.

7. Service and guarantee commitment

BENTLY NEVADA backs the 330709-000-050-10-02-00 with a 5-year warranty, covering defects in materials and workmanship. Their global technical support team provides 24/7 assistance for installation, calibration, and troubleshooting, including localized support for hazardous area compliance. Customers gain access to calibration certificates, installation guides, and compatibility tools via BENTLY’s online portal. Spare parts, including replacement cables and mounting studs, are stocked globally for rapid delivery. For critical applications, on-site validation services ensure the sensor meets performance specifications, reinforcing BENTLY’s commitment to reliable condition monitoring.