Description

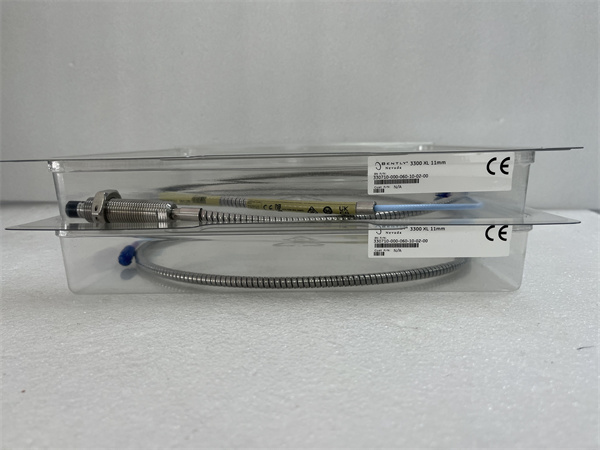

1. Product overview

The BENTLY 330710 – 000 – 60 – 10 – 02 – 00 is an extension cable that is an integral part of the BENTLY 3300 series proximity sensor systems. These systems are widely renowned in the industrial domain for their role in machinery health monitoring, especially in measuring the displacement, vibration, and position of rotating equipment components. The 330710 – 000 – 60 – 10 – 02 – 00 extension cable plays a crucial part in ensuring seamless connectivity between the various components of the sensor system, facilitating the accurate transmission of data from the sensor to the monitoring and control units.

2. Parameter list

| Parameter name | Parameter value |

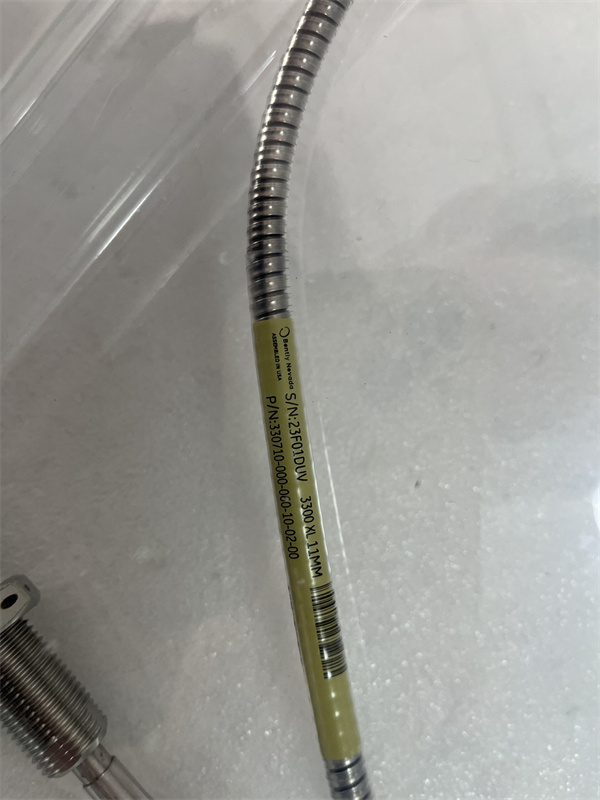

| Product model | 330710 – 000 – 60 – 10 – 02 – 00 |

| Manufacturer | BENTLY NEVADA |

| Product category | Extension cable for 3300 series proximity sensor systems |

| Cable length | The ’10’ in the model indicates a length of 1.0 metre (3.3 feet), providing sufficient reach for installations where the sensor and the receiving unit are not in close proximity. This length can be adjusted according to specific application requirements, and the cable is designed to maintain signal integrity over this distance. |

| Connector type | Features a ’02’ type miniature coaxial click – loc connector. This type of connector is known for its secure connection, which minimizes the risk of signal loss due to accidental disconnection. It also ensures easy and quick installation and removal, which is beneficial during maintenance or system reconfiguration. |

| Cable construction | Built with high – quality materials to withstand the rigors of industrial environments. The cable is shielded to protect against electromagnetic interference, which is common in industrial settings where there are multiple electrical and electronic devices operating simultaneously. This shielding helps in maintaining the purity of the sensor signals being transmitted. |

| Overall case length | The ‘060’ in the model corresponds to an overall case length of 60 mm. This dimension is important for proper integration within the sensor system housing or mounting brackets, ensuring a compact and neat installation. |

| Unthreaded length | The ‘000’ in the model indicates an unthreaded length of 00 mm, which might be relevant for specific mounting or connection requirements where a non – threaded section is preferred. |

| Operating temperature range | Designed to operate within a wide temperature range, typically from – 40 °C to + 85 °C. This allows the cable to be used in various industrial applications, whether in cold storage facilities or high – temperature manufacturing plants. |

| Certification | Likely meets relevant industry certifications such as RoHS (Restriction of Hazardous Substances) to ensure environmental compliance. However, it is advisable to check with BENTLY NEVADA directly for the exact list of certifications. |

BENTLY 330710-000-60-10-02-00

3. Product features and technical highlights

Signal integrity over distance: One of the key features of the 330710 – 000 – 60 – 10 – 02 – 00 extension cable is its ability to maintain signal integrity over its 1 – metre length. The high – quality shielding and cable construction materials are engineered to minimize signal attenuation and interference. In industrial settings, where there are often electromagnetic fields generated by motors, transformers, and other electrical equipment, this is crucial. For example, in a large power generation plant, the proximity sensors need to be installed at various locations on the turbines. The 330710 – 000 – 60 – 10 – 02 – 00 extension cable can be used to connect these sensors to the control room, ensuring that the data about turbine shaft vibration and displacement is accurately transmitted without any loss or distortion of the signal.

Reliable and secure connector: The miniature coaxial click – loc connector offers a reliable and secure connection. Its design allows for a quick and easy connection process, reducing installation time. At the same time, the click – loc mechanism ensures that the connection remains firm during operation, even in environments with vibrations or mechanical stress. In a manufacturing plant where machinery is constantly in motion, this secure connection prevents any accidental disconnection of the cable, which could lead to inaccurate data readings or system malfunctions.

Durability in harsh environments: With its wide operating temperature range and robust construction, the cable can withstand harsh industrial environments. In outdoor applications, such as wind turbines, it can endure extreme cold or hot weather conditions. In addition, it is resistant to dust, moisture, and chemical exposure to some extent, depending on the specific environmental conditions. For instance, in a chemical processing plant, where there may be exposure to corrosive chemicals in the air, the cable’s construction materials help protect it from degradation, ensuring long – term reliable operation.

4. Typical application scenarios

Rotating machinery monitoring in power plants: In power plants, steam turbines, generators, and other rotating machinery are critical components. The 330710 – 000 – 60 – 10 – 02 – 00 extension cable is used to connect proximity sensors to the monitoring systems. These sensors measure the shaft vibration, displacement, and axial position of the rotating parts. By accurately transmitting the sensor data, the cable enables operators to monitor the health of the machinery in real – time. For example, if there is a sudden increase in shaft vibration due to a bearing problem in a steam turbine, the proximity sensor connected via this extension cable will send the data to the control system, allowing for timely maintenance and preventing potential catastrophic failures.

Industrial manufacturing equipment: In manufacturing plants, high – speed motors, conveyor belts, and robotic arms often require precise monitoring of their movement and position. Proximity sensors connected by the 330710 – 000 – 60 – 10 – 02 – 00 extension cable can provide this information. For instance, in an automotive assembly line, the cable can be used to connect sensors on robotic arms that are responsible for assembling parts. By accurately measuring the position and movement of the robotic arms, the cable – sensor combination ensures that the parts are assembled with high precision, reducing the risk of defective products.

Oil and gas industry: In the oil and gas industry, pumps, compressors, and other equipment are used in various processes. The 330710 – 000 – 60 – 10 – 02 – 00 extension cable is used to connect proximity sensors to the monitoring systems in these applications. These sensors can detect the wear and tear of pump impellers or the misalignment of compressor shafts. In an offshore oil rig, where equipment is exposed to harsh marine environments, the cable’s ability to withstand these conditions while maintaining signal integrity is highly valuable. The data transmitted through the cable helps in predicting equipment failures and scheduling maintenance, reducing downtime and increasing the overall efficiency of the operation.

BENTLY 330710-000-60-10-02-00

5. Installation and maintenance guidelines

Installation: Before installation, carefully review the installation manual provided by BENTLY NEVADA. Ensure that the installation environment is clean and free from any sharp objects that could damage the cable. When installing, make sure to align the miniature coaxial click – loc connector correctly and firmly click it into place. Check the cable for any signs of damage, such as cuts or kinks, before connecting it. Route the cable in a way that avoids contact with hot surfaces, moving parts, or areas with high electromagnetic fields. Secure the cable using appropriate cable ties or mounting brackets to prevent it from moving or getting tangled. Connect the cable to the sensor and the receiving unit according to the wiring diagram provided in the manual, and double – check all connections for tightness.

Maintenance: Regularly inspect the 330710 – 000 – 60 – 10 – 02 – 00 extension cable for any signs of physical damage, such as cracks in the outer sheath, loose connections, or exposed wires. Clean the cable surface periodically to remove dust and debris, especially in dusty environments. Check the signal transmission quality by comparing the data received at the monitoring unit with the expected values. If there are any issues with the signal, such as weak or erratic readings, first check the connections. If the problem persists, refer to the troubleshooting guide in the manual. In case of a malfunction, contact BENTLY’s technical support team for assistance. Periodically, check for any updates or advisories from BENTLY regarding the cable to ensure optimal performance.

6. Service and support

BENTLY NEVADA typically offers a warranty for the 330710 – 000 – 60 – 10 – 02 – 00 extension cable, covering defects in materials and workmanship. The exact duration of the warranty can be obtained through official BENTLY channels. Their global technical support team is available to assist customers with installation, commissioning, and troubleshooting. Customers can access a wealth of online resources, including detailed installation manuals, wiring diagrams, and technical documentation, on BENTLY’s official website. In the event of a product failure, BENTLY stocks a sufficient inventory of replacement cables, ensuring quick replacement and minimizing downtime for industrial operations that rely on this component. They also offer training programs for customers to help them better understand the proper installation and maintenance of the extension cable, enhancing the overall user experience and promoting long – term reliable use of the product.