Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/05-01-01-00-00-01 |

| Manufacturer | Bently Nevada |

| Product category | Enhanced rack interface module |

| Electrical performance | 24V DC power supply (from 3500/15 127610-01); Power consumption: 3.8W max |

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

| Interface type | Backplane connector for 3500 series rack; 10/100/1000Base-T Ethernet port; RS-485 serial port; USB Type-C port |

| Communication protocols | Modbus TCP/IP; Bently Nevada proprietary protocol; ASCII; Profinet |

| Data transfer rate | Ethernet: 1000 Mbps; RS-485: 230.4 kbps max; USB: 5 Gbps |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing) |

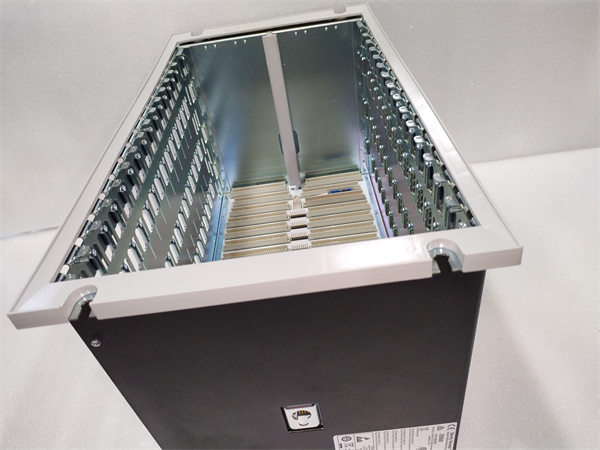

| Installation method | Rack-mountable in 3500 series racks; Occupies 1 standard slot |

| Compatibility | Works with 330851-02-000-060-10-00-00, 3500/33-01-00, 3500/42M 140734-02, and 170180-01-00 software (v5.0+) |

BENTLY 3500/05-01-01-00-00-01

Product introduction

The Bently Nevada 3500/05-01-01-00-00-01 is an upgraded rack interface module, building on the capabilities of the 3500/05-01-01-00-00-00 with enhanced connectivity and protocol support. It serves as a high-performance communication gateway for the 3500 series machinery protection system, enabling faster data transmission and broader integration with modern industrial networks.

Designed to meet the demands of Industry 4.0, this module retains the core function of aggregating data from sensors like the 330851-02-000-060-10-00-00 and modules such as the 3500/33-01-00, while introducing gigabit Ethernet and Profinet support. This makes it ideal for large-scale industrial environments where high-speed data transfer and compatibility with advanced automation systems are critical.

Powered by the 3500/15 127610-01 redundant power supply, the 3500/05-01-01-00-00-01 ensures uninterrupted communication, even in safety-critical applications. Its rugged design mirrors the reliability of its predecessor, with added features to support future-proofing industrial monitoring networks.

Core advantages and technical highlights (compared to 3500/05-01-01-00-00-00)

Gigabit Ethernet performance: The 3500/05-01-01-00-00-01 upgrades to a 1000 Mbps Ethernet port, 10x faster than the 100 Mbps port in the 3500/05-01-01-00-00-00. This high-speed connectivity enables real-time transmission of large datasets—such as continuous vibration waveforms from the 3500/33-01-00 or high-resolution spectral data from the 3500/42M 140734-02—critical for advanced analytics and machine learning applications in smart factories.

Expanded protocol support: In addition to Modbus TCP/IP and RS-485 protocols, this module adds Profinet compatibility, a key industrial Ethernet standard used in automotive, packaging, and process industries. This allows seamless integration with Profinet-based PLCs and SCADA systems, eliminating the need for protocol converters and simplifying network architecture compared to the 3500/05-01-01-00-00-00.

USB Type-C interface: A new USB Type-C port (5 Gbps) facilitates direct local connectivity for quick configuration, firmware updates, or data logging. This feature streamlines maintenance—technicians can connect a laptop to configure the module without network access, a significant improvement over the 3500/05-01-01-00-00-00, which relies solely on Ethernet or RS-485 for setup.

Enhanced data throughput: With a 230.4 kbps max rate on the RS-485 port (double the 115.2 kbps of the 3500/05-01-01-00-00-00), the module can handle more concurrent data streams from legacy devices. This is particularly useful in retrofit projects where multiple older sensors or actuators (paired with the 3500/62 module) need to communicate with the 3500 system.

Typical application scenarios

In an automotive manufacturing plant, the 3500/05-01-01-00-00-01 connects a 3500 series rack monitoring robotic arm motors to the factory’s Profinet network. It transmits vibration data from 330851-02-000-060-10-00-00 transducers (processed by the 3500/33-01-00) via gigabit Ethernet, enabling real-time analysis in the plant’s MES system. The Profinet support allows direct integration with the robotic control system, triggering maintenance alerts before motor failure disrupts production—a capability not possible with the 3500/05-01-01-00-00-00’s protocol set.

At a large-scale LNG plant, the module aggregates data from 20+ 3500/42M 140734-02 signal conditioners monitoring compressors and pumps. Its gigabit Ethernet port streams high-frequency vibration data to a cloud-based analytics platform, while the RS-485 port communicates with legacy pressure controllers. During a scheduled shutdown, technicians use the USB Type-C port to quickly update firmware, reducing maintenance time by 50% compared to using network-based updates with the 3500/05-01-01-00-00-00.

In a smart grid substation, the 3500/05-01-01-00-00-01 monitors transformer vibration via the 330851-02-000-060-10-00-00 and 3500/33-01-00. Its Profinet interface connects to the substation’s Siemens S7 PLC, while gigabit Ethernet links to a central SCADA system. The high data transfer rate ensures that transient vibration spikes (indicating internal arcing) are transmitted in milliseconds, allowing the PLC to trigger cooling system adjustments faster than with the 3500/05-01-01-00-00-00.

BENTLY 3500/05-01-01-00-00-01

Related model recommendations

3500/05-01-01-00-00-00: Predecessor model, useful for comparison in mixed-system environments.

330851-02-000-060-10-00-00: Proximity transducer whose high-resolution data benefits from the 3500/05-01-01-00-00-01’s gigabit Ethernet.

3500/15 127610-01: Redundant power supply ensuring stable operation for the module’s enhanced features.

3500/42M 140734-02: Signal conditioner whose multi-channel data is efficiently transmitted via the module’s high-speed ports.

170180-01-00 (v5.0+): Updated software supporting the 3500/05-01-01-00-00-01’s Profinet configuration.

3500/92: Advanced gateway that pairs with the module to extend Profinet connectivity across multiple 3500 racks.

3500/62: Digital I/O module whose status data is transmitted faster via the module’s upgraded RS-485 port.

Installation, commissioning and maintenance instructions

Installation preparation: Similar to the 3500/05-01-01-00-00-00, mount the 3500/05-01-01-00-00-01 in a single rack slot with screws torqued to 0.6 Nm, ensuring the 3500/15 127610-01 power supply is disconnected during installation. Use Cat6a cable for gigabit Ethernet connections to maximize throughput, and shielded twisted-pair for RS-485. The USB Type-C port can be used for initial configuration via 170180-01-00 software (v5.0+), simplifying setup in network-isolated environments.

Maintenance suggestions: In addition to the quarterly inspections recommended for the 3500/05-01-01-00-00-00, verify gigabit Ethernet link speed monthly using network diagnostic tools. Test Profinet communication with downstream devices semi-annually to ensure compatibility. Use the USB Type-C port for firmware updates (preferred over network updates for speed and reliability). If data throughput drops, check for Cat6a cable damage or network congestion—common issues with gigabit connections not faced by the 100 Mbps predecessor.

Service and guarantee commitment

The 3500/05-01-01-00-00-01 comes with a 24-month warranty (extended from the 18-month coverage of the 3500/05-01-01-00-00-00), covering defects in its enhanced components such as the gigabit Ethernet port, USB interface, and Profinet circuitry. Bently Nevada’s global service team provides specialized support for Profinet configuration, with remote diagnostics via the gigabit port for faster troubleshooting. Extended warranty options (up to 4 years) include annual performance validation of high-speed communication features, ensuring the module remains optimized for advanced industrial networks.