Description

Detailed parameter table

| Parameter name | Parameter value |

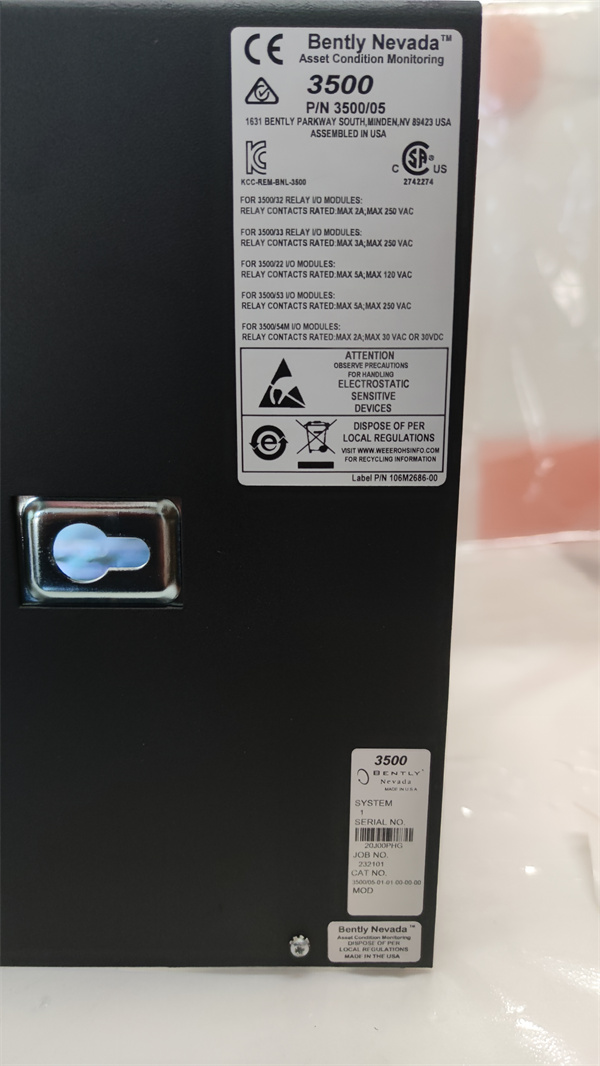

| Product model | 3500/05-01-03-00-00-00 |

| Manufacturer | Bently Nevada |

| Product category | Advanced rack interface module with enhanced security |

| Electrical performance | 24V DC power supply (from 106M1079-01 or 3500/15 127610-01); Power consumption: 3.9W max |

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

| Interface type | Backplane connector for 3500 series rack; 10/100/1000Base-T Ethernet port; RS-485 serial port; Optical fiber port (multimode) |

| Communication protocols | Modbus TCP/IP; Bently Nevada proprietary protocol; ASCII; Modbus RTU over fiber; SNMPv3 |

| Data transfer rate | Ethernet: 1000 Mbps; RS-485: 230.4 kbps max; Optical fiber: 100 Mbps |

| Security features | SSL/TLS encryption; Role-based access control (RBAC); Secure firmware updates |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing) |

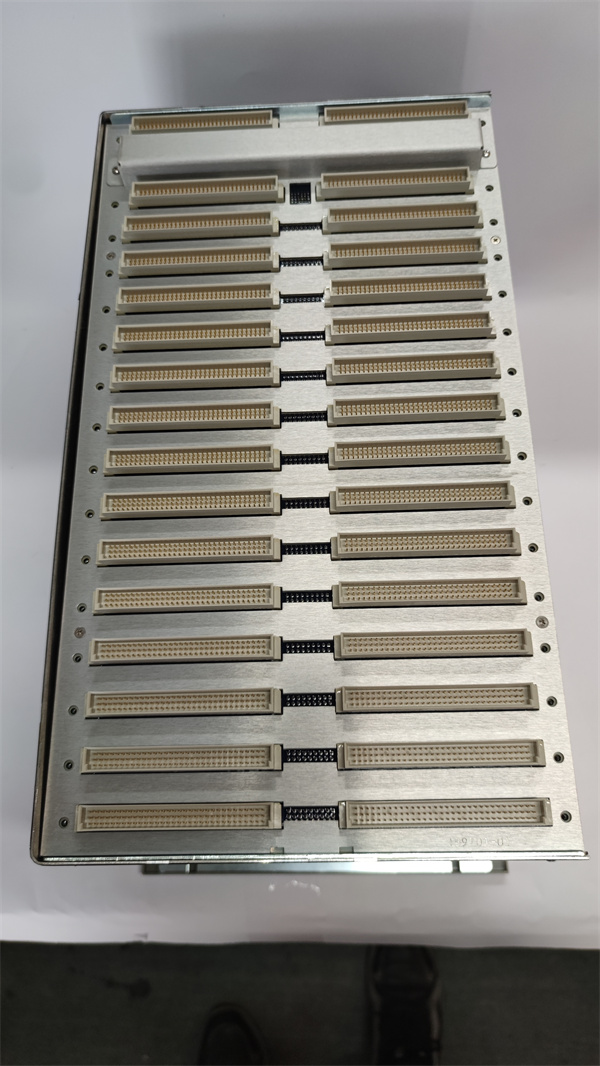

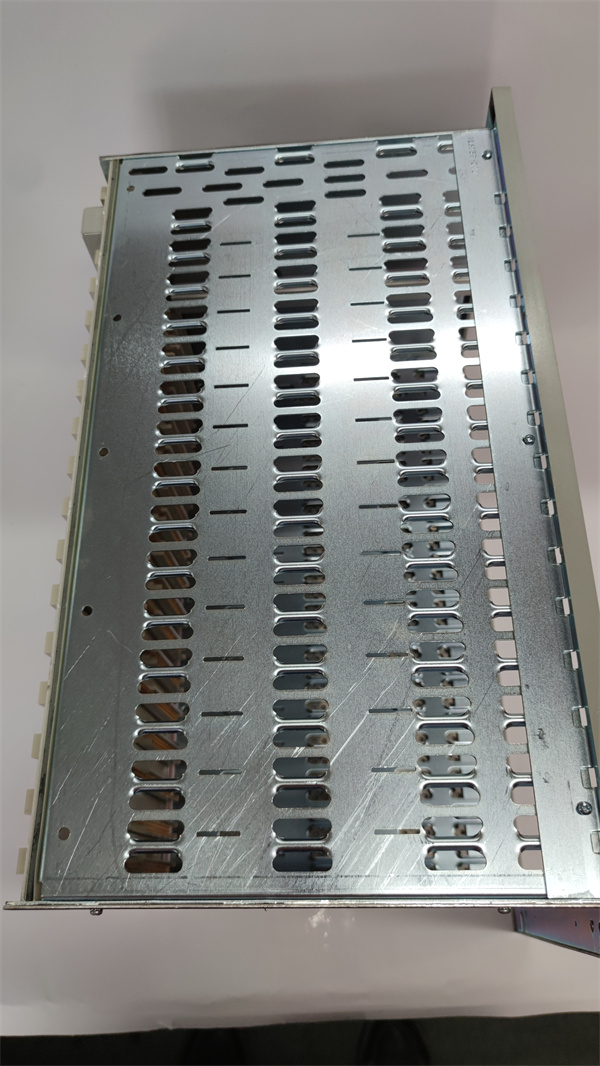

| Installation method | Rack-mountable in 3500 series racks; Occupies 1 standard slot |

| Compatibility | Works with 3500/50 286566-02, 3500/33-1-00, 85515-02, 106M1079-01, and 170180-01-00 software (v6.0+) |

BENTLY 3500/05-01-03-00-00-00

Product introduction

The Bently Nevada 3500/05-01-03-00-00-00 is an advanced rack interface module with enhanced security features, designed to serve as a secure communication gateway for 3500 series machinery protection systems. Building on the capabilities of previous interface modules, it integrates high-speed connectivity with robust security protocols, making it ideal for industrial environments where data integrity and protection against unauthorized access are critical.

As a central communication hub, this module aggregates data from key components such as the 3500/33-1-00 vibration monitoring module and 85515-02 vibration transmitter, then securely transmits it to operator interfaces like the 3500/50 286566-02 and remote systems. Its gigabit Ethernet and optical fiber ports ensure high-speed, reliable data transfer, while advanced security features—including encryption and role-based access control—safeguard sensitive machinery data from cyber threats.

Powered by reliable supplies such as the 106M1079-01 or 3500/15 127610-01, the 3500/05-01-03-00-00-00 is engineered to withstand harsh industrial conditions, from power plants to chemical facilities. Its compatibility with the 3500/50 286566-02 ensures seamless integration into existing monitoring ecosystems, providing operators with secure, real-time access to critical machinery health data.

Core advantages and technical highlights

Enhanced security architecture: The 3500/05-01-03-00-00-00 incorporates industry-leading security features, including SSL/TLS encryption for data in transit and role-based access control (RBAC) to restrict configuration changes. This protects against unauthorized access to sensitive vibration data from the 3500/33-1-00, a critical safeguard in industries like energy and chemicals where cyber threats could disrupt operations. Secure firmware updates prevent tampering during module upgrades, ensuring the system remains protected against emerging vulnerabilities.

Gigabit Ethernet performance: With a 1000 Mbps Ethernet port, this module delivers 10x faster data transfer than 100 Mbps predecessors, enabling real-time transmission of large datasets—such as high-resolution vibration waveforms from the 3500/33-1-00 or continuous trend data from the 85515-02. This speed is particularly valuable for integrating with the 3500/50 286566-02’s color touchscreen, which relies on fast data refresh rates to display detailed graphs and heat maps without lag.

Dual-path communication redundancy: Combining gigabit Ethernet, RS-485, and optical fiber ports, the 3500/05-01-03-00-00-00 offers multiple communication paths, ensuring uninterrupted data flow even if one channel fails. For example, if the Ethernet link to the 3500/50 286566-02 is disrupted, data automatically routes through the optical fiber port, maintaining visibility of critical alarms from the 3500/33-1-00. This redundancy is essential for safety-critical applications where data loss could lead to equipment damage.

Seamless integration with advanced interfaces: The module is optimized for compatibility with the 3500/50 286566-02, supporting its high-speed data requirements and enabling secure communication between the rack and the operator interface. It also works with 170180-01-00 software (v6.0+) to provide encrypted remote access, allowing engineers to configure the 3500 system or analyze data without compromising security.

Typical application scenarios

In a nuclear power plant, the 3500/05-01-03-00-00-00 serves as the secure communication gateway for a 3500 system monitoring reactor coolant pumps. It encrypts vibration data from 3500/33-1-00 modules and transmits it via gigabit Ethernet to the 3500/50 286566-02 in the control room, ensuring operators have real-time access to critical parameters while protecting against cyber intrusions. The optical fiber port provides a separate, EMI-resistant link to a remote backup system, ensuring data redundancy in compliance with safety regulations.

At a large chemical processing facility, the module connects to multiple 3500/33-1-00 modules monitoring compressor vibration, aggregating data and sending it to both the 3500/50 286566-02 (local interface) and a cloud-based analytics platform (via encrypted Ethernet). Role-based access control restricts configuration changes to authorized engineers, while SSL/TLS encryption protects data as it travels to the cloud. If the primary Ethernet link fails, the RS-485 port maintains communication with legacy PLCs, preventing production disruptions.

In an offshore wind farm, the 3500/05-01-03-00-00-00 operates in a harsh marine environment, connecting 85515-02 transmitters on turbine bearings to the 3500/50 286566-02 in the on-site control container. Its optical fiber port transmits data over long distances (up to 2 km) between turbine nacelles and the control center, avoiding signal loss in the windy, EMI-prone environment. Secure remote access via 170180-01-00 software allows onshore engineers to monitor turbine health without physically accessing the offshore facility.

BENTLY 3500/05-01-03-00-00-00

Related model recommendations

3500/50 286566-02: Advanced operator interface module that receives secure data from the 3500/05-01-03-00-00-00.

3500/33-1-00: Vibration monitoring module whose data is aggregated and secured by the 3500/05-01-03-00-00-00.

85515-02: Vibration transmitter whose measurements are transmitted via the module to upstream systems.

106M1079-01: Power supply unit providing stable 24V DC to the 3500/05-01-03-00-00-00 in mid-sized systems.

3500/15 127610-01: Redundant power supply ensuring uninterrupted operation in critical applications.

170180-01-00 software (v6.0+): Tool for secure remote configuration and data analysis via the 3500/05-01-03-00-00-00.

3500/04-01: System monitoring module whose status data is encrypted and transmitted by the 3500/05-01-03-00-00-00.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3500/05-01-03-00-00-00 in a single slot of the 3500 series rack, ensuring the system is powered off (via 106M1079-01 or 3500/15 127610-01) during installation. Secure the module with screws torqued to 0.6 Nm, verifying proper alignment with the backplane connector. Connect gigabit Ethernet using shielded Cat6a cable for maximum speed, and optical fiber with appropriate connectors (ensuring minimum bend radius). Configure initial security settings (e.g., admin password) before connecting to the network.

Commissioning steps: Power on the system and confirm the module initializes (indicated by a steady power LED). Use 170180-01-00 software (v6.0+) to configure communication protocols, security settings (SSL/TLS certificates, RBAC roles), and data routing—ensuring encrypted links to the 3500/50 286566-02. Test data transmission through all ports, verifying that vibration data from the 3500/33-1-00 appears on the 3500/50 286566-02 within 500ms. Perform a security audit to confirm encryption and access controls are functioning correctly.

Maintenance suggestions: Inspect the 3500/05-01-03-00-00-00 quarterly, checking Ethernet, fiber, and RS-485 connections for corrosion or looseness. Update firmware semi-annually via secure channels (encrypted USB or Ethernet) to patch security vulnerabilities. Review access logs monthly using 170180-01-00 software to detect unauthorized access attempts. Test communication redundancy annually by disconnecting primary ports and verifying failover to secondary paths. If security features malfunction or ports fail, replace the module during a scheduled shutdown—hot-swapping is supported but requires reconfiguration of security settings.

Service and guarantee commitment

The 3500/05-01-03-00-00-00 is backed by a 30-month warranty (matching the 3500/50 286566-02) covering manufacturing defects, including security protocol failures, communication port malfunctions, or encryption issues. During this period, Bently Nevada provides free repair or replacement, along with technical support for configuring security features and integrating with the 3500/50 286566-02 and power supplies like the 106M1079-01.

Our global cybersecurity team offers specialized 24/7 support for security-related issues, including certificate management and vulnerability patching. Extended warranty options (up to 5 years) include annual security audits, firmware updates, and priority response to emerging threats. Built on Bently Nevada’s commitment to secure industrial communication, the 3500/05-01-03-00-00-00 is guaranteed to protect critical machinery data while enabling seamless integration with advanced operator interfaces.