Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/33-1-00 |

| Manufacturer | Bently Nevada |

| Product category | Vibration monitoring module |

| Electrical performance | 24V DC power supply (from 106M1079-01 or 3500/15 127610-01); Power consumption: 5.5W max |

| Measurement channels | 4 vibration channels |

| Measurement range | ±25 mm/s peak velocity; ±500 μm peak-to-peak displacement |

| Frequency response | 10 Hz to 1000 Hz |

| Interface type | Backplane connector for 3500 series rack; BNC input connectors |

| Alarm capabilities | 2 programmable alarm levels per channel (Warning, Danger); Relay outputs for system integration |

| Data output | 4-20 mA analog outputs; Digital status via backplane |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing) |

| Installation method | Rack-mountable in 3500 series racks; Occupies 1 standard slot |

| Compatibility | Works with 3500/04-01, 3500/50M, 85515-02, and 170180-01-00 software |

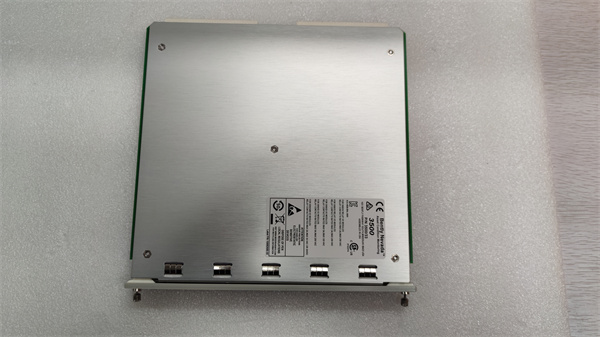

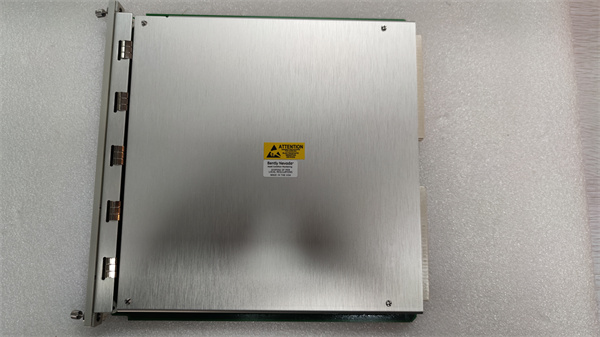

BENTLY 3500/33-1-00

Product introduction

The Bently Nevada 3500/33-1-00 is a high-performance vibration monitoring module, specifically engineered to track the dynamic behavior of rotating machinery. As a key component of the 3500 series machinery protection system, it processes vibration signals from sensors like the 85515-02 vibration transmitter, converting raw data into actionable insights for operators and maintenance teams.

Unlike general-purpose monitoring modules, the 3500/33-1-00 is dedicated to vibration analysis, offering 4 independent channels to monitor multiple points on a single machine or across several pieces of equipment. It communicates seamlessly with the 3500/04-01 system monitoring module, providing real-time health status updates to ensure the entire monitoring infrastructure remains aware of machinery conditions.

Powered by reliable supplies such as the 106M1079-01 or 3500/15 127610-01, this module is built to thrive in harsh industrial environments—from power plant turbine halls to offshore oil rigs. Its ability to detect early signs of machinery degradation, such as bearing wear or rotor imbalance, makes it indispensable for preventing unplanned downtime and ensuring operational safety.

Core advantages and technical highlights

Multi-channel precision monitoring: With 4 independent channels, the 3500/33-1-00 can simultaneously track vibration levels at critical points on rotating machinery—such as motor bearings, pump impellers, or turbine shafts. Each channel offers a wide measurement range (±25 mm/s velocity, ±500 μm displacement) and precise frequency response (10 Hz to 1000 Hz), ensuring accurate detection of both low-frequency issues (e.g., misalignment) and high-frequency problems (e.g., gear mesh faults).

Configurable alarm thresholds: The module supports 2 programmable alarm levels (Warning, Danger) per channel, allowing customization to specific machinery requirements. For example, a “Warning” could trigger at 10 mm/s on a pump bearing, while “Danger” activates at 15 mm/s—alerting operators via the 3500/50M interface before damage occurs. Alarm settings are easily configured via 170180-01-00 software, with thresholds stored in non-volatile memory to survive power cycles.

Seamless system integration: The 3500/33-1-00 communicates with the 3500/04-01 system monitoring module via the backplane, enabling centralized oversight of vibration monitoring health. If a channel fails or a sensor (like the 85515-02) disconnects, the 3500/04-01 detects the fault and triggers a system-level alert, ensuring no monitoring gaps go unnoticed. Its 4-20 mA analog outputs also allow direct integration with PLCs or DCS systems for broader automation integration.

Rugged design for industrial reliability: Built to withstand extreme temperatures (-40°C to +70°C) and high humidity, the 3500/33-1-00 performs reliably in harsh conditions. Its BNC input connectors are shielded to minimize electromagnetic interference, ensuring accurate signal processing even near large motors or high-voltage equipment. This durability reduces maintenance requirements and ensures consistent performance in critical applications.

Typical application scenarios

In a coal-fired power plant, the 3500/33-1-00 monitors vibration on a steam turbine generator, with 4 channels connected to 85515-02 transmitters at the front and rear bearings. During startup, it detects elevated vibration at 1X frequency (indicating rotor imbalance) and triggers a “Warning” alarm on the 3500/50M. Operators use this data to schedule a balancing procedure during the next shutdown, avoiding costly unplanned outages. The 3500/04-01 tracks the module’s health, ensuring continuous monitoring even as plant conditions fluctuate.

At a chemical processing facility, the module oversees 4 centrifugal pumps, with each channel monitoring a pump’s drive-end bearing. When a pump experiences bearing degradation, the 3500/33-1-00 detects increasing high-frequency vibration and activates a “Danger” alarm. This triggers a relay output, which shuts down the pump via the 3500/62 digital I/O module, preventing catastrophic failure and chemical leaks. The 3500/04-01 logs the event, providing a timestamped record for post-incident analysis.

On an offshore oil platform, the 3500/33-1-00 operates in a salt-laden, high-humidity environment, monitoring vibration on a gas compressor. Its rugged design resists corrosion, while the 3500/15 127610-01 redundant power supply ensures uninterrupted operation during storm-related voltage fluctuations. Data from the module is transmitted via the 3500/05-01-02-00-00-00 interface module to an onshore control center, with the 3500/04-01 ensuring the link remains stable despite harsh weather conditions.

BENTLY 3500/33-1-00

Related model recommendations

3500/04-01: System monitoring module that tracks the 3500/33-1-00’s health and channel status.

3500/50M: Operator interface module that displays vibration data and alarms from the 3500/33-1-00.

85515-02: Vibration transmitter whose signals are processed by the 3500/33-1-00.

106M1079-01: Power supply unit for smaller systems using the 3500/33-1-00.

3500/15 127610-01: Redundant power supply for critical applications requiring uninterrupted vibration monitoring.

170180-01-00 software: Tool for configuring alarm thresholds and analyzing vibration trends from the 3500/33-1-00.

3500/62: Digital I/O module that acts on alarms triggered by the 3500/33-1-00.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3500/33-1-00 in a single slot of the 3500 series rack, ensuring the system is powered off (via 106M1079-01 or 3500/15 127610-01) during installation. Secure the module with screws torqued to 0.6 Nm, verifying proper alignment with the backplane connector. Connect 85515-02 transmitters or other vibration sensors to the BNC inputs using shielded coaxial cable, ensuring tight connections to minimize noise.

Commissioning steps: Power on the system and confirm the 3500/33-1-00 initializes correctly (indicated by a steady power LED). Use 170180-01-00 software to configure each channel’s measurement type (velocity or displacement), frequency range, and alarm thresholds. Calibrate inputs using a vibration calibrator, verifying that 0 mm/s = 4 mA and full-scale = 20 mA on the analog outputs. Test alarm functionality by applying a test signal exceeding the “Danger” threshold and confirming the 3500/50M displays the alert.

Maintenance suggestions: Inspect the 3500/33-1-00 quarterly, checking BNC connectors for corrosion or loose connections. Clean connectors with a dry cloth if needed. Verify alarm settings and analog output accuracy semi-annually using calibration equipment. Download vibration trends monthly via 170180-01-00 software to identify machinery degradation patterns. If a channel fails or alarms are erratic, replace the module during a scheduled shutdown—hot-swapping is supported but should be done with caution to avoid data loss.

Service and guarantee commitment

The 3500/33-1-00 is backed by a 24-month warranty covering manufacturing defects, including measurement inaccuracies, channel failures, or alarm relay malfunctions. During this period, Bently Nevada provides free repair or replacement, along with technical support for configuring the module and integrating it with the 3500/04-01 and power supplies like the 106M1079-01.

Our global service team offers 24/7 assistance for troubleshooting vibration monitoring issues, with remote diagnostics available via the 3500/05-01-02-00-00-00 to verify signal processing and alarm settings. Extended warranty options (up to 4 years) include annual calibration checks to ensure measurement accuracy. Built on Bently Nevada’s expertise in machinery protection, the 3500/33-1-00 is guaranteed to deliver reliable vibration monitoring, helping operators detect and address machinery issues before they escalate.