Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/44M 176449-03 |

| Manufacturer | Bently Nevada |

| Product category | High-performance 4-channel dynamic signal analysis module |

| Electrical performance | 24V DC power supply (from 3500/91 190782-01 or 3500/15 127610-01); Power consumption: 7.8W max |

| Physical size | Width: 48.8mm, Height: 241.3mm, Depth: 242mm |

| Input channels | 4 high-speed dynamic signal channels |

| Input types supported | Proximity probes (3300 XL/5000 series), IEPE accelerometers, piezoelectric sensors, 4-20 mA dynamic signals |

| Signal processing | 24-bit ADC; Sampling rate: 51.2 kHz per channel; FFT analysis (up to 65536 points); Time waveform capture |

| Frequency response | 0.05 Hz to 20 kHz (configurable with advanced filtering) |

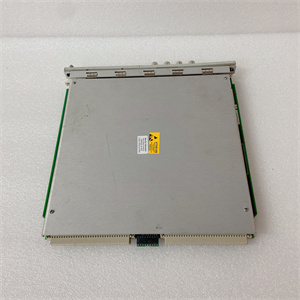

| Interface type | Backplane connector; BNC input connectors; Ethernet (10/100Base-T) for data export; LED status indicators per channel |

| Data storage | 64GB SSD for waveform captures and spectral data archives |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing); IP20 front panel |

| Installation method | Rack-mountable in 3500 series racks; Occupies 2 standard slots |

| Compatibility | Works with 3500/53M, 3500/53 133388-01, 3500/60, 3500/91 190782-01, and 170180-01-00 software (v7.0+) |

BENTLY 3500/44M 176449-03

Product introduction

The Bently Nevada 3500/44M 176449-03 is a high-performance 4-channel dynamic signal analysis module, engineered to deliver advanced diagnostic capabilities for critical rotating machinery. Building on the foundational monitoring features of the 3500/44-01-00, this module elevates signal processing precision and data capture capacity, making it indispensable for applications requiring deep insights into machinery health—such as gas turbines, large compressors, and high-speed generators.

Unlike the 3500/44-01-00, which focuses on reliable mid-range monitoring, the 3500/44M 176449-03 is designed for predictive diagnostics. It captures high-resolution time waveforms and performs sophisticated frequency analysis to detect incipient faults—like early-stage bearing degradation or gear tooth wear—that might elude standard monitoring modules. This makes it a cornerstone of predictive maintenance programs in industries where unplanned downtime carries significant costs.

Powered by stable supplies such as the 3500/91 190782-01, the module operates reliably in harsh industrial environments, from offshore platforms to power plant turbine halls. Its seamless integration with controllers like the 3500/53M allows for centralized analysis, while Ethernet connectivity enables secure export of diagnostic data to enterprise systems—bridging the gap between local monitoring and global asset management.

Core advantages and technical highlights

Superior signal fidelity: Equipped with a 24-bit ADC (vs. 16-bit in the 3500/44-01-00) and 51.2 kHz sampling rate (double the 3500/44-01-00’s 25.6 kHz), the 3500/44M 176449-03 captures micro-variations in vibration signals. This precision is critical for detecting subtle fault indicators, such as the high-frequency harmonics generated by early bearing fatigue, which would be filtered out by lower-resolution systems.

Advanced spectral analysis: With FFT capability up to 65536 points (8x more than the 3500/44-01-00’s 8192), the module generates ultra-detailed frequency spectra. This allows engineers to distinguish between closely spaced frequencies—for example, identifying a 1 Hz difference between gear mesh harmonics in a high-speed compressor, which indicates progressive tooth wear.

Onboard data archiving: The 64GB SSD (a feature absent in the 3500/44-01-00) stores hours of high-resolution waveforms and spectra, triggered automatically by alarms from the 3500/53M or manually via the 3500/50 286566-02 interface. This archive is invaluable for post-failure analysis—for instance, reconstructing the vibration signature leading up to a turbine trip to determine root cause.

Enhanced connectivity: Unlike the 3500/44-01-00, which relies solely on backplane communication, the 3500/44M 176449-03 includes an Ethernet port for direct data export. This enables real-time sharing of diagnostic data with 170180-01-00 software, supporting remote analysis by experts without onsite visits—critical for offshore or remote installations.

Comparison with 3500/44-01-00

| Feature | 3500/44M 176449-03 | 3500/44-01-00 |

| ADC resolution | 24-bit | 16-bit |

| Max sampling rate | 51.2 kHz | 25.6 kHz |

| FFT points | Up to 65536 | Up to 8192 |

| Data storage | 64GB SSD | None (relies on controller) |

| Connectivity | Backplane + Ethernet | Backplane only |

| Power consumption | 7.8W | 6.2W |

| Ideal application | Critical machinery (turbines, compressors) requiring predictive diagnostics | Mid-range assets (pumps, fans) needing reliable monitoring |

Typical application scenarios

In a combined-cycle power plant, the 3500/44M 176449-03 monitors a gas turbine’s high-pressure rotor, paired with the 3500/53M controller. Its 24-bit ADC detects faint vibration spikes at 3x rotor speed—indicative of incipient blade damage—months before the 3500/44-01-00 (monitoring a secondary pump) would flag issues. The SSD archives waveforms, and Ethernet transmission allows remote experts to analyze data via 170180-01-00 software, scheduling a repair during a planned outage.

At an LNG processing facility, the module monitors a large centrifugal compressor. Its high-resolution FFT identifies sidebands around the impeller frequency, indicating impeller unbalance due to liquid carryover. The 3500/53M uses this data to trigger a warning via the 3500/60, while the 3500/44M 176449-03 stores pre-alarm waveforms for later analysis. This prevents catastrophic failure, which would cost millions in downtime.

On an offshore drilling rig, the module monitors a subsea mud pump, operating in a harsh environment powered by the 3500/91 190782-01. Its 51.2 kHz sampling rate captures high-frequency vibration from bearing defects in the pump’s gearbox—signals that would be missed by the 3500/44-01-00 monitoring a nearby auxiliary pump. Ethernet connectivity transmits data to onshore engineers, who recommend proactive bearing replacement during the next rig shutdown.

BENTLY 3500/44M 176449-03

Related model recommendations

3500/53M: Advanced controller that leverages the 3500/44M 176449-03’s diagnostic data for complex alarm logic.

3500/91 190782-01: Redundant power supply ensuring stable operation during high-speed data capture.

3500/50 286566-02: Operator interface for real-time visualization of FFT spectra and waveform captures.

3300 XL Proximity Probes: High-precision sensors whose signals are optimally processed by the module’s 24-bit ADC.

170180-01-00 software (v7.0+): Tool for advanced analysis of archived waveforms and frequency spectra.

3500/05-01-03-00-00-00: Secure rack interface for encrypted transmission of diagnostic data.

3500/60: Digital output module that executes protective actions based on critical faults detected by the 3500/44M 176449-03.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3500/44M 176449-03 in 2 consecutive slots of the 3500 rack, adjacent to the 3500/53M for low-latency data transfer. Power off via the 3500/91 190782-01 before installation. Secure with screws torqued to 0.6 Nm, verifying backplane alignment. Connect sensors using low-noise shielded cables; IEPE devices use integrated 24V excitation. Link Ethernet to the plant network for remote access.

Commissioning steps: Power on via the 3500/91 190782-01 and confirm all LEDs illuminate. Use 170180-01-00 software to configure sampling rates, FFT resolution, and trigger conditions (e.g., “Vibration > 20 mm/s” or “Manual trigger via 3500/50 286566-02”). Calibrate with a precision signal generator, verifying amplitude accuracy across 0.05 Hz to 20 kHz. Test data export by capturing a waveform and confirming it appears in the software. Validate communication with the 3500/53M by checking that spectral data triggers configured alarms.

Maintenance suggestions: Inspect quarterly, cleaning BNC connectors with isopropyl alcohol to prevent noise. Verify ADC linearity semi-annually using a multi-frequency calibrator. Monitor SSD health annually—replace if write errors exceed 0.1%. Update firmware quarterly via Ethernet to access new diagnostic features. Coordinate module replacement with 3500/91 190782-01 maintenance to avoid data loss. Unlike the 3500/44-01-00, schedule annual performance validation by Bently-certified technicians for critical applications.

Service and guarantee commitment

The 3500/44M 176449-03 is backed by a 30-month warranty (extended from the 3500/44-01-00’s 24 months) covering ADC inaccuracies, SSD failures, or Ethernet port issues. During this period, Bently provides free repair/replacement and dedicated technical support for advanced configuration—including optimizing FFT settings for specific machinery types.

Our diagnostic experts offer 24/7 remote assistance via the 3500/05-01-03-00-00-00, analyzing archived waveforms to help identify fault patterns. Extended warranty options (up to 5 years) include annual calibration, firmware updates, and priority access to replacement modules. Built on Bently’s legacy of precision diagnostics, this module guarantees the actionable insights needed to maximize uptime of critical machinery.